Buttweld Fittings 180 Degree Bend

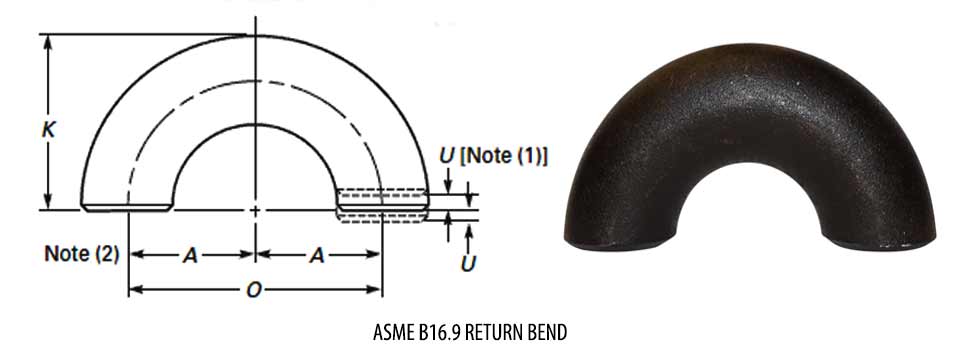

ASME B16.9 180 Degree U Bend

Table of Content

Kaizen Steel Industries is a leading exporter and supplier of high-quality 180 Degree Pipe Bends. These pipe bends are essential for changing the direction of flow in a pipe system by 180 degrees. They are used to connect two sections of pipe while altering the flow direction.

Our 180 Degree Pipe Bends are produced using advanced pipe bending machines that ensure precision and efficiency, reducing the time required for large-scale projects. The bends are commonly used in various industries including oil and gas, petrochemical, and refinery sectors.

We ensure that all our 180 Degree Bends are manufactured to the highest standards and undergo rigorous testing. Our attentive team selects only the best products for manufacturing, ensuring top performance and durability.

Kaizen Steel offers competitive pricing and reliable delivery for all your pipe bending needs.

Why Choose Kaizen Steel Industries

- 100% Tested Products: All 180 Degree Elbow fittings from Kaizen Steel Industries are rigorously tested to meet international manufacturing standards. Our elbows are produced in ISO 9001 certified factories and come with Material Test Certificates (MTC) as per EN 10204 3.1.

- Best Price Guaranteed: By sourcing directly from the manufacturer and stockholder, Kaizen Steel Industries ensures competitive pricing, allowing us to offer high quantity discounts and work closely with customers to meet their project needs.

- Fast Quotations and Delivery: We understand the urgency in procurement. With extensive stocks of standard size 180 Degree Elbows and other fittings, we are able to provide quick quotations and immediate delivery to both domestic and international clients.

- Quality Raw Materials: Kaizen Steel Industries uses only high-quality raw materials for manufacturing seamless and welded 180 Degree Elbows. Our materials undergo strict quality testing before production.

- Standard and Custom Sizes: We provide both standard and non-standard sizes for seamless and welded buttweld pipe fittings, ensuring prompt delivery regardless of size requirements.

- Complete Documentation: Kaizen Steel Industries provides comprehensive product-related documentation before delivery, ensuring transparency and compliance with customer requirements.

180 Degree Bends Specifications

| Specification | Details |

| Dimensions | ASME/ANSI B16.9, ASME B16.28 |

| Size | 1/2″ NB to 48″ NB |

| Type | Seamless / Welded / Fabricated |

| Bending Radius (R) | 1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

180 Degree Pipe Bend Material & Grades

| Material | Grades |

| Stainless Steel | ASTM A403 WP316/316L, ASTM A403 SA / A 774 WP-S, WP-W, WP-WX 304/304L, ASTM A182 F316L, 304L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 |

| Duplex & Super Duplex Steel | ASTM A815, ASME SA815 UNS NO S31803, S32205, UNS S32750, S32950, Werkstoff No. 1.4462 |

| Carbon Steel | ASTM A234, ASME SA234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70 |

| Low Temperature Carbon Steel | ASTM A420 WPL3, A420 WPL6 |

| Alloy Steel | ASTM / ASME A/SA 234 Gr. WP1, WP5, WP9, WP11, WP12, WP22, WP91 |

| Nickel Alloy | ASTM B336, ASME SB336, Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade I & II), Cupro-Nickel 70/30, CuNi10Fe1Mn, CuNi30Mn1Fe |

Sizing and Dimensions of 180 Degree Return Bend

| NPS (Inch) | Dia. Nominal | O.D. at Bevel (mm) | Center-to-Center (O) | Back-to-Face (K) | ||

|---|---|---|---|---|---|---|

| LR | SR | LR | SR | |||

| 1/2 | 15 | 21.3 | 76 | 48 | ||

| 1 | 25 | 33.4 | 76 | 51 | 56 | 41 |

| 1-1/4 | 32 | 42.2 | 95 | 64 | 70 | 52 |

| 1-1/2 | 40 | 48.3 | 114 | 76 | 83 | 62 |

| 2 | 50 | 60.3 | 152 | 102 | 106 | 81 |

| 2-1/2 | 65 | 73.0 | 190 | 127 | 132 | 100 |

| 3 | 80 | 88.9 | 229 | 152 | 159 | 121 |

| 3-1/2 | 90 | 101.6 | 267 | 178 | 184 | 140 |

| 4 | 100 | 114.3 | 305 | 203 | 210 | 159 |

| 5 | 125 | 141.3 | 381 | 254 | 262 | 197 |

| 6 | 150 | 168.3 | 457 | 305 | 313 | 237 |

| 8 | 200 | 219.1 | 610 | 406 | 414 | 313 |

| 10 | 250 | 273.0 | 762 | 508 | 518 | 391 |

| 12 | 300 | 323.8 | 914 | 610 | 619 | 467 |

| 14 | 350 | 355.6 | 1067 | 711 | 711 | 533 |

| 16 | 400 | 406.4 | 1219 | 813 | 813 | 610 |

| 18 | 450 | 457 | 1372 | 914 | 914 | 686 |

| 20 | 500 | 508 | 1524 | 1016 | 1016 | 762 |

| 22 | 550 | 559 | 1676 | 1118 | 1118 | 838 |

| 24 | 600 | 610 | 1829 | 1219 | 1219 | 914 |

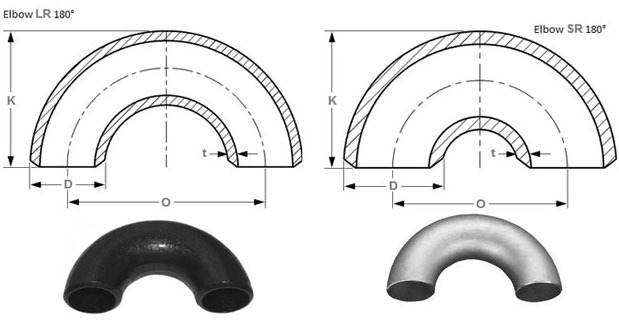

Types of 180 Degree U Bend

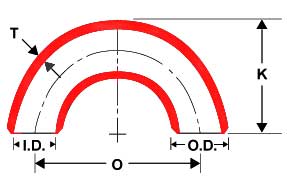

Long Radius 180 Return Bends Dimensions

| N.P.S | Wall Thickness | I.D. | Back To Face | Pipe Sch. | O.D. | Center To Center | Wgt Pounds |

|---|---|---|---|---|---|---|---|

| 1/2 | 0.109 | 0.622 | 1.88 | 40 | 0.84 | 3 | 0.32 |

| 3/4 | 0.113 | 0.824 | 1.69 | 40 | 1.05 | 2.25 | 0.34 |

| 1 | 0.133 | 1.049 | 2.19 | 40 | 1.31 | 3 | 0.74 |

| 1 1/4 | 0.14 | 1.38 | 2.75 | 40 | 1.66 | 3.75 | 1.1 |

| 1 1/2 | 0.145 | 1.61 | 3.25 | 40 | 1.9 | 4.5 | 1.6 |

| 2 | 0.154 | 2.067 | 4.19 | 40 | 2.38 | 6 | 3.2 |

| 2 1/2 | 0.203 | 2.469 | 5.19 | 40 | 2.88 | 7.5 | 6.1 |

| 3 | 0.216 | 3.068 | 6.25 | 40 | 3.5 | 9 | 9.4 |

| 3 1/2 | 0.226 | 3.548 | 7.25 | 40 | 4 | 10.5 | 12.8 |

| 4 | 0.237 | 4.026 | 8.25 | 40 | 4.5 | 12 | 17.5 |

| 5 | 0.258 | 5.047 | 10.31 | 40 | 5.56 | 15 | 29.3 |

| 6 | 0.28 | 6.065 | 12.31 | 40 | 6.63 | 18 | 47 |

| 8 | 0.322 | 7.981 | 16.31 | 40 | 8.63 | 24 | 87 |

| 10 | 0.365 | 10.02 | 20.38 | 40 | 10.75 | 30 | 164 |

| 12 | 0.375 | 12 | 24.38 | * | 12.75 | 36 | 237 |

| 14 | 0.375 | 13.25 | 28 | 30 | 14 | 42 | 311 |

| 16 | 0.375 | 15.25 | 32 | 30 | 16 | 48 | 408 |

| 18 | 0.375 | 17.25 | 36 | * | 18 | 54 | 514 |

| 20 | 0.375 | 19.25 | 40 | 20 | 20 | 60 | 636 |

Short Radius 180 Return Bends Weight

| Nominal Pipe Size | Pipe Schedule | O.D. | Center to Center O | I.D. | Wall Thickness T | Weight Pounds | Back to Face K |

|---|---|---|---|---|---|---|---|

| 1 | 40 | 1.32 | 2 | 1.05 | 0.133 | 0.5 | 1.62 |

| 1 1/4 | 40 | 1.66 | 2.5 | 1.38 | 0.14 | 0.8 | 2.06 |

| 1 1/2 | 40 | 1.9 | 3 | 1.61 | 0.145 | 1.1 | 2.44 |

| 2 | 40 | 2.38 | 4 | 2.07 | 0.154 | 1.9 | 3.19 |

| 2 1/2 | 40 | 2.88 | 5 | 2.47 | 0.203 | 4 | 3.94 |

| 3 | 40 | 3.5 | 6 | 3.07 | 0.216 | 6 | 4.75 |

| 3 1/2 | 40 | 4 | 7 | 3.55 | 0.226 | 8.7 | 5.5 |

| 4 | 40 | 4.5 | 8 | 4.03 | 0.237 | 12.2 | 6.25 |

| 5 | 40 | 5.56 | 10 | 5.05 | 0.258 | 19.2 | 7.75 |

| 6 | 40 | 6.62 | 12 | 6.07 | 0.28 | 32.9 | 9.31 |

| 8 | 40 | 8.62 | 16 | 7.98 | 0.322 | 64.9 | 12.31 |

| 10 | 40 | 10.75 | 20 | 10.02 | 0.365 | 112 | 15.38 |

| 12 | * | 12.75 | 24 | 12 | 0.375 | 157 | 18.38 |

| 14 | 30 | 14 | 28 | 13.25 | 0.375 | 208 | 21 |

| 16 | 30 | 16 | 32 | 15.25 | 0.375 | 257 | 24 |

| 18 | * | 18 | 36 | 17.25 | 0.375 | 325 | 27 |

| 20 | 20 | 20 | 40 | 19.25 | 0.375 | 416 | 30 |

| 24 | 20 | 24 | 48 | 23.25 | 0.375 | 592 | 36 |

180 Degree Bends Application Industries

180-degree pipe bends are essential components in various industries due to their ability to change the direction of flow in piping systems. These bends find applications in several sectors, including:

- Off-Shore Oil Drilling Companies: Used for connecting pipes and equipment in harsh marine environments.

- Power Generation: Facilitates the transportation of steam, water, and gases within power plants.

- Petrochemicals: Essential for handling chemicals and hydrocarbons in refining processes.

- Gas Processing: Used to navigate and control gas flow in processing plants.

- Specialty Chemicals: Important for managing the flow of specialized chemicals in production facilities.

- Pharmaceuticals: Utilized in pharmaceutical manufacturing processes for handling various fluids and chemicals.

- Pharmaceutical Equipment: Applied in equipment used for drug production and processing.

- Chemical Equipment: Integral to the functionality of equipment used in chemical manufacturing.

- Sea Water Equipment: Employed in systems dealing with seawater, often in desalination plants.

- Heat Exchangers: Used in heat exchange systems to direct fluids and optimize thermal transfer.

- Condensers: Helps in the efficient operation of condensers by guiding flow paths.

- Pulp and Paper Industry: Facilitates the movement of pulps and chemicals in paper production processes.

Kaizen Steel Industries Export to

Burundi, Comoros, Djibouti, Eritrea, Ethiopia, Kenya, Madagascar, Malawi, Mauritius, Mayotte, Mozambique, Reunion, Rwanda, Seychelles, Somalia, Tanzania, United Republic of Uganda, Zambia, Zimbabwe, Angola, Cameroon, Central African Republic, Chad, Congo (Brazzaville), Congo, Democratic Republic of the Equatorial Guinea, Gabon, Sao Tome and Principe, Algeria, Egypt, Libyan Arab Jamahiriya, Morroco, South Sudan, Sudan, Tunisia, Western Sahara, Botswana, Lesotho, Namibia, South Africa, Swaziland, Benin, Burkina Faso, Cape Verde, Cote d\\’Ivoire (Ivory Coast), Gambia, Ghana, Guinea, Guinea-Bissau, Liberia, Mali, Mauritania, Niger, Nigeria, Saint Helena, Senegal, Sierra Leone, Togo

Anguilla, Antigua and Barbuda, Aruba, Bahamas, Barbados, Bonaire, Saint Eustatius and Saba, British Virgin Islands, Cayman Islands, Cuba, Curaçao, Dominica, Dominican Republic, Grenada, Guadeloupe, Haiti, Jamaica, Martinique, Monserrat, Puerto Rico, Saint-Barthélemy, St. Kitts and Nevis, Saint Lucia, Saint Martin, Saint Vincent and the Grenadines, Sint Maarten, Trinidad and Tobago, Turks and Caicos Islands, Virgin Islands (US), Belize, Costa Rica, El Salvador, Guatemala, Honduras, Mexico, Nicaragua, Panama, Argentina, Bolivia, Brazil, Chile, Colombia, Ecuador, Falkland Islands (Malvinas), French Guiana, Guyana, Paraguay, Peru, Suriname, Uruguay, Venezuela, Bermuda, Canada, Greenland, Saint Pierre and Miquelon, United States

Afghanistan, Armenia, Azerbaijan, Bangladesh, Bhutan, Brunei Darussalam, Cambodia, China, Georgia, Hong Kong, India, Indonesia, Japan, Kazakhstan, South Korea, Kyrgyzstan, Laos, Macao, Malaysia, Maldives, Mongolia, Myanmar (ex-Burma), Nepal, Phillipines, Singapore, Sri Lanka (ex-Ceilan), Taiwan, Tajikistan, Thailand, Timor Leste (West), Turkmenistan, Uzbekistan, Vietnam

Albania, Andorra, Belarus, Bosnia, Croatia, European Union, Faroe Islands, Gibraltar, Guerney and Alderney, Iceland, Jersey, Kosovo, Liechtenstein, Macedonia, Man, Island of Moldova, Monaco, Montenegro, Norway, Russia, San Marino, Serbia, Svalbard and Jan Mayen Islands, Switzerland, Turkey, Ukraine, Vatican City State (Holy See)

Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, United Kingdom

Bahrain, Iraq, Iran, Israel, Jordan, Kuwait, Lebanon, Oman, Palestine, Qatar, Saudi Arabia, Syria, United Arab Emirates, Yemen

Request a Quote

Our Products

Related Products

Weldable Pipe Fittings

Know More

Stainless Steel Long Radius Elbow

Know More

45 Degree Elbow Manufacturers

Know More

Alloy Steel Pipe Fittings

Know More