ANSI / ASME B16.5 Reducing Flange

Table of Content

- Reducing Flanges Specification

- Reducing Flange Material & Grades

- Type of ASME B16.5 Reducing Flanges

- Reducing Flange Standards

- ASME B16.5 Reducing Flanges Dimensions

- ANSI B16.5 Class 150 Reducing Threaded Flange

- ASME B16.5 Reducing Flanges Size Chart

- DIN86029 PN10 Reducing Flanges Pressure Ratings

- Reducing Flange Industries and Applications

Kaizen Steel Industries specializes in the manufacturing, stocking, supplying, and exporting of ANSI B16.5 Reducing Flanges. Also known as reducer flanges, these are used to connect pipes of different sizes without needing a separate reducer. For reducing flanges, the flange’s density should match that of the larger radius.

Reducing flanges come in various types, including blind, slip-on, threaded, and weld neck flanges. They are available in all pressure classes and provide a reliable option for connecting pipes of different sizes. The end preparations for reducing flanges include butt weld, socket weld, threaded, and slip-on, with sizes ranging from 1/2” to 24” nominal size and pressure classes from 150# to 2500#. They can have Raised Face (RF), Flat Face, or Ring Type Joint (RTJ) facing, among others.

Reducing flanges are beneficial because they are easier to bolt up compared to non-reducing flanges. They are ideal for connecting flanges of different sizes and are available in various types and pressures. These flanges are fixed by welding or using connecting pieces of equal range, offering a straightforward and cost-effective way to join flanges of different sizes.

We supply and export a wide range of reducing flanges, including ASME B16.5 SS Reducing Flanges, Reducing Copper Flanges, Reducing Threaded Flanges, Reducing Blind Flanges, Eccentric Reducing Flanges, Reducing Flat Face Flanges, Grooved Reducing Flanges, Reducing Hub Flanges, Reducing Lap Joint Flanges, NPT Reducing Slip-On Flanges, and Reducing Socket Weld Flanges.

Reducing Flanges Specification

| ASME B16.5 Reducing Flange Size Chart | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

|---|---|

| Reducing Flanges b16.5 Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Reducing Flange, ASME Reducing Flange, BS Reducing Flange, DIN Reducing Flange, EN Reducing Flange, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| ANSI B16.5 Reducing Flangese Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS Reducing Flange |

| Stainless Steel Reducing Flanges Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 Reducing Flange |

| JIS ANSI B16.5 Class 150 reducing threaded flange | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K Reducing Flange |

| UNI ASME B16.5 Reducing Flanges | 6Bar 10Bar 16Bar 25Bar 40Bar Reducing Flange |

| EN ASTM A182 SS reducing wn flange | 6Bar 10Bar 16Bar 25Bar 40Bar Reducing Flange |

| Coating For Alloy Steel reducing Flanges socket weld | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized Reducing Flange |

| Most common types of Reducing Flange | Forged / Threaded / Screwed / Plate |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production technique |

|

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Special design | As per your drawing AS, ANSI, BS, DIN and JIS |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Origin | Indian / West Europe / Japan / USA / Korean |

| Manufacturer of ASME B16.47 Series A and B Reducing Flanges | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc.

|

| Reducing Flange Uses & application |

|

| Export to Carbon Steel Reducing Flange | Ireland, Singapore, Indonesia, Ukraine, Saudi Arabia, Spain, Canada, USA, Brazil, Thailand, Korea, Iran, India, Egypt, Oman, Dubai, Peru, etc |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Reducing Flange Material & Grades

| Carbon Steel Reducing Flange | ASTM/ASME A/SA105 A/SA105N & A/SA216-WCB, DIN 1.0402, DIN 1.0460, DIN 1.0619, Die Steel, ASTM A105 / ASME SA105, A105N, ASTM A350 LF2 / ASME SA350, High Yield CS ASTM A694 / A694 (F52 F56 F60 F65 F70 F80) |

|---|---|

| Stainless Steel Reducings Flanges | ASTM/ASME A/SA182 F304, F304L, F316, F316L, ASTM/ASME A/SA351 CF8, CF3, CF8M, CF3M, DIN 1.4301, DIN 1.4306, DIN 1.4401, DIN 1.4404, DIN 1.4308, DIN 1.4408, DIN 1.4306, DIN 1.4409 |

| Alloy Steel reducings Flanges socket weld | ASTM A182 / ASME SA182 F5, F9, F11, F12, F22, F91 |

| Titanium Reducings Flange | ASTM B381 / ASME SB381, Titanium Gr. 1, Titanium Gr. 2, Titanium Gr. 4, Titanium Gr. 5, Titanium Gr. 7 ASTM R50250/GR.1 | R50400/GR.2 | R50550/GR.3 | R50700/GR.4 | GR.6 |R52400/GR.7 | R53400/GR.12 | R56320/GR.9 |R56400/GR.5 |

| Copper Reducings Flange | T1, T2, C10100, C10200, C10300, C10400, C10500, C10700, C10800, C10910,C10920, TP1, TP2, C10930, C11000, C11300, C11400, C11500, C11600, C12000,C12200, C12300, TU1, TU2, C12500, C14200, C14420, C14500, C14510, C14520, C14530, C17200, C19200, C21000, C23000, C26000, C27000, C27400, C28000, C33000, C33200, C37000, C44300, C44400, C44500, C60800, C63020, C68700, C70400, C70600, C70620, C71000, C71500, C71520, C71640, etc |

| Copper Nickel Reducings Flanges | ASTM / ASME SB 61 / 62 / 151 / 152, Copper Nickel 90/10 (C70600 ), Cupro Nickel 70/30 (C71500), UNS C71640 |

| Brass Reducings Flange | 3602 / 2604 / H59 / H62 / etc. |

| Inconel reducings pipe Flanges | ASTM B564 / ASME SB564, Inconel 600, 601, 625, 718, 783, 690, x750 Flange |

| Hastelloy C22 Reducings Flange | ASTM B564 / ASME SB564, Hastelloy C276 (UNS N10276), C22 (UNS N06022), C4, C2000, B2, B3, X Flange |

| Monel Reducings Flange | ASTM B564 / ASME SB564, Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500) |

| Alloy 20 Reducings Flanges | ASTM B462 / ASME SB462, Carpenter® 20 Alloy, Alloy 20Cb-3 |

| Aluminium Reducings Flange | 5052 /6061/ 6063 / 2017 / 7075 / etc. |

| Nickel Reducings Flange | ASTM B564 / ASME SB564, Nickel 200, Nickel 201, Nickel 205, Nickel 205LC |

| Duplex Steel reducings Flanges slip on | S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Super Duplex Steel reducings Flanges slip on | S32750 / S32760 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Inconel reducings pipe Flanges | ASTM B564 / ASME SB564, Incoloy 800, 800H, 800HT (UNS N08800), 825 (UNS N08825), 925 Flange |

| 254 Smo Reducings Flange | ASTM A182 / ASME SA182, SMO 254/6Mo, UNS S31254, DIN 1.4547 |

| Nimonic Reducings Flange | Nimonic 75, Nimonic 80A, Nimonic 90 |

| Other DIN86029 PN10 Reducings Flanges Material | Tin bronze, Alumunum bronze, Lead bronze |

Type of ASME B16.5 Reducing Flanges

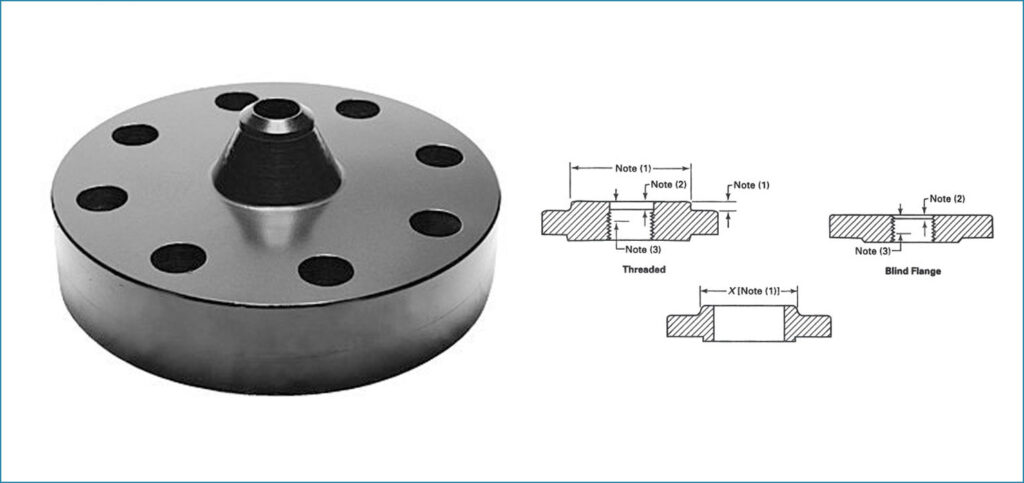

ASME B16.5 Reducing Flanges

ASME B16.5 reducing Flanges without hub

ANSI B16.5 reducing Flanges threaded

ASME B16.47 Series a reducing pipe Flanges

ASME B16.47 Series b reducing Flanges slip on

ANSI B16.5 Class 150 reducing filler flange

ASME B16.5 Class 300 raised face reducing flange

Flat face reducing flange EN 1092-1 Type 02

EN 1092-2 PN16 reducing threaded pipe Flanges

Forged stainless reducing Flanges

AWWA C207 Class d threaded reducing flange

MSS SP-44 class 150 reducing flange

Reducing Flange Standards

| ANSI/ASME B16.47 Flanges | ANSI/ASME B16.36 Flanges | ANSI/ASME B16.5 Flanges | Pr. EN1902-1 Flanges |

| DIN Flanges | JIS Flanges | BS 4504 Flanges | BS 10 Flanges |

| MSS SP-44 Flanges | JIS B2220 Flanges | KS B1503 Flanges | UNI Flanges |

| SABS/SANS 1123 Flanges | AS 2129, AS 4087 Flanges | ISO 9624, ISO 7005-1 Flanges | AWWA Flanges Standard |

| GOST Standard Flanges | API Flanges | AS/ANZ 4331.1 Flanges | Series A Flange |

| Series B Flange | SAE J518 Flanges | GB Flange | Norwegian Standard Flanges |

ASME B16.5 Reducing Flanges Dimensions

ANSI B16.5 Class 150 Reducing Threaded Flange

NPS | DIAMETER | THICKNESS | DIA. | WELDING | MIN. | MIN. | MIN. | NECK | WELDING | JOINT |

DN | O | T | A | B | C | D | E | F | G | H |

1/2 | 5.25 | 1.19 | 1.38 | 0.88 | .90 | 0.93 | 2.88 | 1.56 | 1.56 | |

15 | 133 | 30.5 | 34.9 | 22.2 | 22.9 | 23.5 | 73.0 | 40 | 40 | |

3/4 | 5.50 | 1.25 | 1.69 | 1.09 | 1.11 | 1.14 | 3.12 | 1.69 | 1.69 | |

20 | 140 | 32.0 | 42.9 | 27.8 | 28.2 | 29.0 | 79.4 | 43 | 43 | |

1 | 6.25 | 1.38 | 2.00 | 1.36 | 1.38 | 1.41 | 3.50 | 1.88 | 1.88 | |

25 | 159 | 35.0 | 50.8 | 34.5 | 34.9 | 36.0 | 88.9 | 48 | 48 | |

1 1/4 | 7.25 | 1.50 | 2.50 | 1.70 | 1.72 | 1.75 | 3.75 | 2.06 | 2.06 | |

32 | 184 | 38.5 | 63.5 | 43.3 | 43.7 | 44.5 | 95.2 | 52 | 52 | |

1 1/2 | 8.00 | 1.75 | 2.88 | 1.95 | 1.97 | 1.99 | 4.38 | 2.38 | 2.38 | |

40 | 203 | 44.5 | 73.0 | 49.6 | 50.0 | 50.5 | 111.4 | 60 | 60 | |

2 | 9.25 | 2.00 | 3.62 | To be | 2.44 | 2.46 | 2.50 | 5.00 | 2.75 | 2.75 |

50 | 235 | 51.0 | 92.1 | 61.9 | 62.5 | 63.5 | 127.0 | 70 | 70 | |

2 1/2 | 10.50 | 2.25 | 4.12 | specified | 2.94 | 2.97 | 3.00 | 5.62 | 3.12 | 3.12 |

65 | 267 | 57.5 | 104.8 | 74.6 | 75.4 | 76 | 142.9 | 79 | 79 | |

3 | 12.00 | 2.62 | 5.00 | by | 3.57 | 3.60 | 3.63 | 6.62 | 3.62 | 3.62 |

80 | 305 | 67.0 | 127.0 | 90.7 | 91.4 | 92 | 168.2 | 92 | 92 | |

4 | 14.00 | 3.00 | 6.19 | purchaser | 4.57 | 4.60 | 4.63 | 7.50 | 4.25 | 4.25 |

100 | 356 | 76.5 | 157.2 | 116.1 | 116.8 | 118 | 190.5 | 108 | 108 | |

5 | 16.50 | 3.62 | 7.31 | 5.66 | 5.69 | 5.69 | 9.00 | 5.12 | 5.12 | |

125 | 419 | 92.5 | 185.7 | 143.7 | 144.5 | 145 | 228.6 | 130 | 130 | |

6 | 19.00 | 4.25 | 8.50 | 6.72 | 6.75 | 6.75 | 10.75 | 6.0 | 6.0 | |

150 | 483 | 108.0 | 215.9 | 170.7 | 171.4 | 171 | 273.0 | 152 | 152 | |

8 | 21.75 | 5.00 | 10.62 | 8.72 | 8.75 | 8.75 | 12.50 | 7.0 | 7.0 | |

200 | 552 | 127.0 | 269.9 | 221.5 | 222.2 | 222 | 317.5 | 178 | 178 | |

10 | 26.50 | 6.50 | 12.75 | 10.88 | 10.92 | 10.88 | 16.50 | 9.0 | 9.0 | |

250 | 675 | 165.5 | 323.8 | 276.2 | 277.4 | 276 | 419.4 | 229 | 229 | |

12 | 30.00 | 7.25 | 15.00 | 12.88 | 12.92 | 12.94 | 18.25 | 10.0 | 10.0 | |

300 | 760 | 184.5 | 381.0 | 327.0 | 328.2 | 329 | 463.6 | 254 | 254 |

ASME B16.5 Reducing Flanges Size Chart

| Nominal Size | Type | Ø A | D | Liner Thickness | |

| DN1 | DN2 | ||||

| In. | In. | mm | mm | mm | |

| 3/4″ | 1/2″ | 1 | 98.5 | 30 | 5.0 |

| 1″ | 1/2″ | 1 | 108 | 30 | 5.0 |

| 1″ | 3/4″ | 1 | 108 | 30 | 5.0 |

| 1.1/2″ | 1/2″ | 1 | 127 | 30 | 5.0 |

| 1.1/2″ | 3/4″ | 1 | 127 | 30 | 5.0 |

| 1.1/2″ | 1″ | 1 | 127 | 30 | 5.0 |

| 2″ | 1/2″ | 3 | 152 | 30 | 5.0 |

| 2″ | 3/4″ | 2 | 152 | 30 | 5.0 |

| 2″ | 1″ | 2 | 152 | 30 | 5.0 |

| 2″ | 1.1/2″ | 1 | 152 | 30 | 5.0 |

| 3″ | 3/4″ | 3 | 190.5 | 35 | 5.0 |

| 3″ | 1″ | 3 | 190.5 | 35 | 5.0 |

| 3″ | 1.1/2″ | 2 | 190.5 | 35 | 5.0 |

| 3″ | 2″ | 1 | 190.5 | 35 | 5.0 |

| 4″ | 3/4″ | 3 | 228.6 | 35 | 5.0 |

| 4″ | 1″ | 3 | 228.6 | 35 | 5.0 |

| 4″ | 1.1/2″ | 3 | 228.6 | 35 | 5.0 |

| 4″ | 2″ | 3 | 228.6 | 35 | 5.0 |

| 4″ | 3″ | 2 | 228.6 | 35 | 5.0 |

| 6″ | 3/4″ | 3 | 280 | 40 | 5.0 |

| 6″ | 1″ | 3 | 280 | 40 | 5.0 |

| 6″ | 1.1/2″ | 3 | 280 | 40 | 5.0 |

| 6″ | 2″ | 3 | 280 | 40 | 5.0 |

| 6″ | 3″ | 3 | 280 | 40 | 5.0 |

| 6″ | 4″ | 2 | 280 | 40 | 5.0 |

| 8″ | 1″ | 3 | 343 | 35 | 5.0 |

| 8″ | 1.1/2″ | 3 | 343 | 35 | 5.0 |

| 8″ | 2″ | 3 | 343 | 40 | 5.0 |

| 8″ | 3″ | 3 | 343 | 40 | 5.0 |

| 8″ | 4″ | 3 | 343 | 40 | 5.0 |

| 8″ | 6″ | 2 | 343 | 40 | 5.0 |

| 10″ | 1″ | 3 | 406 | 35 | 2.5 |

| 10″ | 1.1/2″ | 3 | 406 | 35 | 2.5 |

| 10″ | 2″ | 3 | 406 | 35 | 2.5 |

| 10″ | 3″ | 3 | 406 | 35 | 2.5 |

| 10″ | 4″ | 3 | 406 | 35 | 2.5 |

| 10″ | 6″ | 3 | 406 | 35 | 2.5 |

| 10″ | 8″ | 2 | 406 | 35 | 3.5 |

| 12″ | 1″ | 3 | 483 | 35 | 3.5 |

| 12″ | 1.1/2″ | 3 | 483 | 35 | 3.5 |

| 12″ | 2″ | 3 | 483 | 35 | 3.5 |

| 12″ | 3″ | 3 | 483 | 35 | 3.5 |

| 12″ | 4″ | 3 | 483 | 35 | 3.5 |

| 12″ | 6″ | 3 | 483 | 35 | 3.5 |

| 12″ | 8″ | 3 | 483 | 35 | 3.5 |

| 12″ | 10″ | 2 | 483 | 35 | 3.5 |

| 14″ | 12″ | 1 | 533 | 40 | 3.5 |

| 16″ | 12″ | 3 | 597 | 40 | 3.5 |

| 16″ | 14″ | 2 | 597 | 35 | 3.5 |

DIN86029 PN10 Reducing Flanges Pressure Ratings

| Flanges pressure rating in psig for Reducing Flange ASME | |||||||

| Temperature (F°) | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 285 | 740 | 985 | 1480 | 2220 | 3705 | 6170 |

| 200 | 260 | 680 | 905 | 1360 | 2035 | 3395 | 5655 |

| 300 | 230 | 655 | 870 | 1310 | 1965 | 3270 | 5450 |

| 400 | 200 | 635 | 845 | 1265 | 1900 | 3170 | 5280 |

| 500 | 170 | 605 | 805 | 1205 | 1810 | 3015 | 5025 |

| 600 | 140 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

| 650 | 125 | 550 | 730 | 1100 | 1650 | 2745 | 4575 |

| 700 | 110 | 530 | 710 | 1060 | 1590 | 2655 | 4425 |

| 750 | 95 | 505 | 675 | 1015 | 1520 | 2535 | 4230 |

| 800 | 80 | 410 | 550 | 825 | 1235 | 2055 | 3430 |

| 850 | 65 | 320 | 425 | 640 | 955 | 1595 | 2655 |

| 900 | 50 | 230 | 305 | 460 | 690 | 1150 | 1915 |

| 950 | 35 | 135 | 185 | 275 | 410 | 685 | 1145 |

| 1000 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

Reducing Flange Industries and Applications

Reducing flanges are used in various industries and applications, including:

- Pumps, Valves, and Vessels: In manufacturing and food processing.

- Pipe Connections: For industrial water systems.

- Heat Exchangers and Heating Systems: In all sizes.

- Mining Support: For mining operations.

- Nuclear Power Systems: In nuclear energy facilities.

- Plumbing and Mechanical Systems: For general plumbing and mechanical uses.

- Oil, Gas, and Petrochemical Industries: In various assemblies within these sectors.

Fire Protection Systems: For fire safety applications.

Kaizen Steel Industries Export to

Burundi, Comoros, Djibouti, Eritrea, Ethiopia, Kenya, Madagascar, Malawi, Mauritius, Mayotte, Mozambique, Reunion, Rwanda, Seychelles, Somalia, Tanzania, United Republic of Uganda, Zambia, Zimbabwe, Angola, Cameroon, Central African Republic, Chad, Congo (Brazzaville), Congo, Democratic Republic of the Equatorial Guinea, Gabon, Sao Tome and Principe, Algeria, Egypt, Libyan Arab Jamahiriya, Morroco, South Sudan, Sudan, Tunisia, Western Sahara, Botswana, Lesotho, Namibia, South Africa, Swaziland, Benin, Burkina Faso, Cape Verde, Cote d\\’Ivoire (Ivory Coast), Gambia, Ghana, Guinea, Guinea-Bissau, Liberia, Mali, Mauritania, Niger, Nigeria, Saint Helena, Senegal, Sierra Leone, Togo

Anguilla, Antigua and Barbuda, Aruba, Bahamas, Barbados, Bonaire, Saint Eustatius and Saba, British Virgin Islands, Cayman Islands, Cuba, Curaçao, Dominica, Dominican Republic, Grenada, Guadeloupe, Haiti, Jamaica, Martinique, Monserrat, Puerto Rico, Saint-Barthélemy, St. Kitts and Nevis, Saint Lucia, Saint Martin, Saint Vincent and the Grenadines, Sint Maarten, Trinidad and Tobago, Turks and Caicos Islands, Virgin Islands (US), Belize, Costa Rica, El Salvador, Guatemala, Honduras, Mexico, Nicaragua, Panama, Argentina, Bolivia, Brazil, Chile, Colombia, Ecuador, Falkland Islands (Malvinas), French Guiana, Guyana, Paraguay, Peru, Suriname, Uruguay, Venezuela, Bermuda, Canada, Greenland, Saint Pierre and Miquelon, United States

Afghanistan, Armenia, Azerbaijan, Bangladesh, Bhutan, Brunei Darussalam, Cambodia, China, Georgia, Hong Kong, India, Indonesia, Japan, Kazakhstan, South Korea, Kyrgyzstan, Laos, Macao, Malaysia, Maldives, Mongolia, Myanmar (ex-Burma), Nepal, Phillipines, Singapore, Sri Lanka (ex-Ceilan), Taiwan, Tajikistan, Thailand, Timor Leste (West), Turkmenistan, Uzbekistan, Vietnam

Albania, Andorra, Belarus, Bosnia, Croatia, European Union, Faroe Islands, Gibraltar, Guerney and Alderney, Iceland, Jersey, Kosovo, Liechtenstein, Macedonia, Man, Island of Moldova, Monaco, Montenegro, Norway, Russia, San Marino, Serbia, Svalbard and Jan Mayen Islands, Switzerland, Turkey, Ukraine, Vatican City State (Holy See)

Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, United Kingdom

Bahrain, Iraq, Iran, Israel, Jordan, Kuwait, Lebanon, Oman, Palestine, Qatar, Saudi Arabia, Syria, United Arab Emirates, Yemen