ANSI/ASME B16.5 Blind Flange | BLRF Flange

Table of Content

- Blind Flange Specification

- Blind Flanges Material & Grades

- ASME B16.5 Blind Flanges Type

- ASME B16.5 Blind Flange Dimensions

- JIS Blind Flange Dimensions

- JIS 10K Blind Flange Dimensions

- Blind Flange Weight & Blind Flange Pressure Ratings

- Dimensional Tolerances of ASME B16.5 Blind Flanges

- Applications and Uses of Blind Flanges

Kaizen Steel Industries is a leading exporter of ANSI B16.5 SS Blind Flanges in Mumbai, India, and are also suppliers of CS BLRF Flanges. We offer a range of products including EN 1092-2 PN16 Blind Flanges and MSS SP-44 Class 150 Blind Flanges. We also provide a price list for reducing blind flanges.

Blind flanges are designed without a bore and are used to seal the ends of pipes, valves, and pressure vessel openings. Due to their design, blind flanges, especially those in larger ANSI sizes, are among the most stressed flange types in terms of internal pressure and bolt loading. Most of the stress is bending stress near the center of the flange. The PN16 blind flange dimensions are suitable for high-pressure and high-temperature applications because there is no standard inside diameter.

The B16.5 standard applies to flanges and flanged fittings made from cast or forged materials, including blind flanges and certain reducing flanges made from cast, forged, or plate materials. This standard also covers requirements and recommendations for flange bolting, gaskets, and joints.

ASME B16.5 Blind Flanges are available in a range of sizes. You can view the blind flange size chart here. These flanges typically come in sizes from NPS 1/2 to NPS 24, in both Metric and Inch measurements. The ASME B16.5 standard covers various aspects such as pressure and temperature ratings, materials, dimensions, weight charts, tolerances, testing, marking, and methods for designating openings for pipe flanges and flanged fittings.

The standard includes:

- Blind Flange Dimensions: Available in rating classes 150, 300, 400, 600, 900, and 1500 for sizes NPS 1/2 through NPS 24, and class 2500 for sizes NPS 1/2 through NPS 12. It covers both metric and U.S. Customary units, including bolt diameters and flange bolt holes expressed in inch units.

- Raised Face Fittings: Includes rating classes 150 and 300 for sizes NPS 1/2 through NPS 24. Requirements are specified in both metric and U.S. Customary units, with bolt diameters and flange bolt holes expressed in inch units.

- Flanged Fittings: Available in pressure rating classes 400, 600, 900, and 1500 for sizes NPS 1/2 through NPS 24, and class 2500 for sizes NPS 1/2 through NPS 12, as detailed in Non-Mandatory Appendix E, which provides only U.S. Customary units.

The ASME B16.5 Blind Flange standard should be used alongside equipment specified in other ASME B16 Series standards and other ASME codes, such as the Boiler and Pressure Vessel Code and the B31 Piping Codes.

We are one of the largest manufacturers of blind flanges in India and also supply, distribute, and export class 300 blind flanges.

Blind Flange Specification

| ASME B16.5 Blind Flange Size Chart | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

|---|---|

| BLRF Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Blind Flange, ASME Blind Flange, BS Blind Flange, DIN Blind Flange, EN Blind Flange, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Blind Flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS Blind Flange |

| Blind Flange Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 Blind Flange |

| JIS blind flange raised face | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K Blind Flange |

| UNI blind flange material | 6Bar 10Bar 16Bar 25Bar 40Bar Blind Flange |

| EN slip blind flange | 6Bar 10Bar 16Bar 25Bar 40Bar Blind Flange |

| Coating paddle blind flange | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized Blind Flange |

| Most common types of Blind Flange | Forged / Threaded / Screwed / Plate |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production technique |

|

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Special design | As per your drawing AS, ANSI, BS, DIN and JIS |

| Test EN 1092 blind flange | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Origin | Indian / West Europe / Japan / USA / Korean |

| blind flange manufacturers in india | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc.

|

| din blind flange Uses & application |

|

| Export to ASME B16.5 Blind Flanges | Ireland, Singapore, Indonesia, Ukraine, Saudi Arabia, Spain, Canada, USA, Brazil, Thailand, Korea, Iran, India, Egypt, Oman, Dubai, Peru, etc |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Blind Flanges Material & Grades

| Material Type | Specifications |

|---|---|

| Stainless Steel Blind Flanges | ASTM A182, A240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L |

| Carbon Steel Blind Flanges | ASTM / ASME A/SA 105, ASTM / ASME A 350, ASTM A 181 LF 2, A516 Gr.70, A36, A694 F42, F46, F52, F60, F65, F70 |

| Alloy Steel Blind Flanges | ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91 |

| Duplex Steel Blind Flanges | ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61 |

| Super Duplex Blind Flanges | ASTM / ASME A/SA 182, A240 F 44, F 45, F51, F 53, F 55, F 60, F 61 |

| Nickel Alloy Blind Flanges | Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade I & II) |

| Copper Alloy Blind Flanges | UNS No. C10100, 10200, 10300, 10800, 12000, 12200, 70600, 71500, UNS No. C 70600 (Cu-Ni-90/10), C 71500 (Cu-Ni-70/30) |

| Low Temperature Carbon Steel Blind Flanges | ASTM A350, LF2, LF3 |

ASME B16.5 Blind Flanges Type

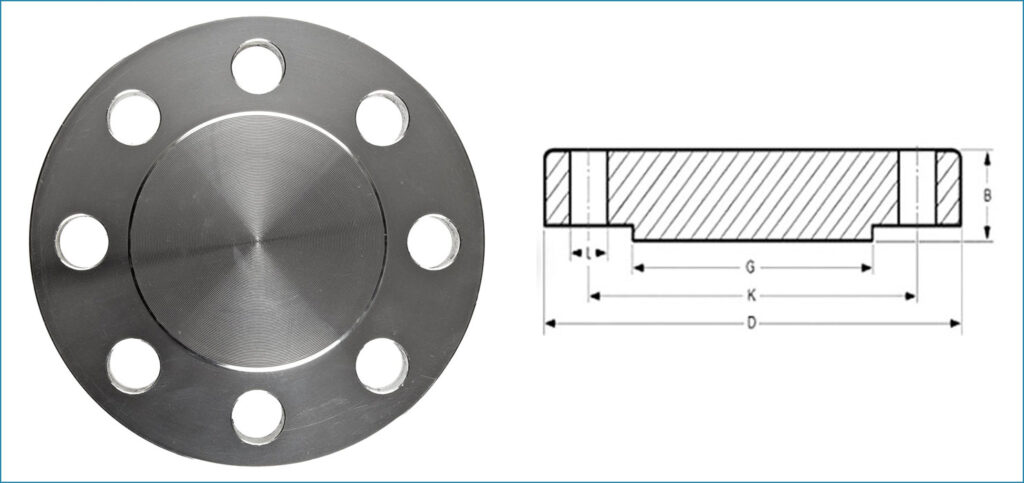

ASME B16.5 Blind Flange

ASME B16.5 BLRF Flange

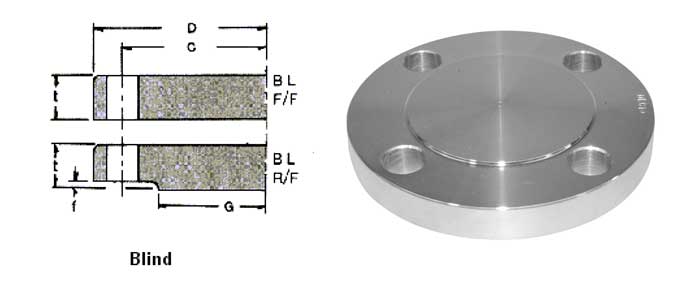

ANSI B16.5 Flat Face Blind Flange

B16.47 Series A Blind Flange Dimensions

ASME B16.5 Blind Flange Dimensions

| Material Type | Specifications |

|---|---|

| Stainless Steel Blind Flanges | ASTM A182, A240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L |

| Carbon Steel Blind Flanges | ASTM / ASME A/SA 105, ASTM / ASME A 350, ASTM A 181 LF 2, A516 Gr.70, A36, A694 F42, F46, F52, F60, F65, F70 |

| Alloy Steel Blind Flanges | ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91 |

| Duplex Steel Blind Flanges | ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61 |

| Super Duplex Blind Flanges | ASTM / ASME A/SA 182, A240 F 44, F 45, F51, F 53, F 55, F 60, F 61 |

| Nickel Alloy Blind Flanges | Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade I & II) |

| Copper Alloy Blind Flanges | UNS No. C10100, 10200, 10300, 10800, 12000, 12200, 70600, 71500, UNS No. C 70600 (Cu-Ni-90/10), C 71500 (Cu-Ni-70/30) |

| Low Temperature Carbon Steel Blind Flanges | ASTM A350, LF2, LF3 |

JIS Blind Flange Dimensions

| Pipe | Pipe | Bo | D | t | T | G | f | r | H | X | C | Holes | Bolt Dia. | |||||||||

| inch | mm | |||||||||||||||||||||

| 3/8 | 10 | 17.3 | 17.8 | +0.5 -0 | 75 | +1.0 -0 | 9 | +1.0 -0 | ±1.0 | 42 | ±0.8 | 1 | +2.0 -0 | +2.0 -0 | 55 | ±0.5 | 4 | 12 | ||||

| 1/2 | 15 | 21.7 | 22.2 | 80 | 9 | 48 | 1 | 60 | 4 | 12 | ||||||||||||

| 3/4 | 20 | 27.2 | 27.7 | 85 | 10 | 52 | 1 | 65 | 4 | 12 | ||||||||||||

| 1 | 25 | 34.0 | 34.5 | 95 | 10 | 62 | 1 | 75 | 4 | 12 | ||||||||||||

| 1-1/4 | 32 | 42.7 | 43.2 | 115 | 12 | 72 | 2 | 90 | 4 | 15 | ||||||||||||

| 1-1/2 | 40 | 48.6 | 49.1 | 120 | 12 | 78 | 2 | 95 | 4 | 15 | ||||||||||||

| 2 | 50 | 60.5 | 61.1 | 130 | 14 | 88 | 2 | 105 | 4 | 15 | ||||||||||||

| 2-1/2 | 65 | 76.3 | 77.1 | 155 | 14 | 112 | 2 | 130 | 4 | 15 | ||||||||||||

| 3 | 80 | 89.1 | 90.0 | 180 | 14 | 125 | 2 | 145 | 4 | 19 | ||||||||||||

| 3-1/2 | 90 | 101.6 | 102.6 | +1.0 -0 | 190 | 14 | 135 | 2 | 155 | 4 | 19 | |||||||||||

| 4 | 100 | 114.3 | 115.4 | 200 | 16 | 145 | 2 | 165 | 8 | 19 | ||||||||||||

| 5 | 125 | 139.8 | 141.2 | 235 | 16 | 180 | 2 | 200 | 8 | 19 | ||||||||||||

| 6 | 150 | 165.2 | 166.6 | 265 | 18 | 210 | 2 | 230 | 8 | 19 | ||||||||||||

| 7 | 175 | 190.7 | 192.1 | 300 | 18 | 235 | ±0.9 | 2 | 260 | ±0.6 | 8 | 23 | ||||||||||

| 8 | 200 | 216.3 | 218.0 | 320 | +1.5 -0 | 20 | 255 | 2 | 280 | 8 | 23 | |||||||||||

| 9 | 225 | 241.8 | 243.7 | 345 | 20 | 280 | 2 | 305 | 12 | 23 | ||||||||||||

| 10 | 250 | 267.4 | 269.5 | 385 | 22 | +1.5 -0 | 32 | 320 | 2 | 5 | 286 | 290 | 345 | 12 | 23 | |||||||

| 12 | 300 | 318.5 | 321.0 | 430 | 22 | 34 | 365 | 3 | 5 | 338 | 342 | 390 | 12 | 23 | ||||||||

| 14 | 350 | 355.6 | 358.1 | 480 | 24 | 36 | 405 | 3 | 5 | 378 | 382 | 435 | 12 | 25 | ||||||||

| 16 | 400 | 406.4 | 409.0 | +1.5 -0 | 540 | 24 | 36 | 465 | 3 | 5 | 432 | 436 | 495 | 16 | 25 | |||||||

| 18 | 450 | 457.2 | 460.0 | 605 | +2.0 -0 | 24 | 40 | 525 | 3 | 5 | 495 | 500 | 555 | ±0.8 | 16 | 25 | ||||||

| 20 | 500 | 508.0 | 511.0 | 655 | 24 | 40 | 575 | 3 | 5 | 546 | 552 | 605 | 20 | 25 | ||||||||

| 22 | 550 | 558.8 | 562.0 | 720 | 26 | 42 | 630 | 3 | 5 | 597 | 603 | 665 | 20 | 27 | ||||||||

| 24 | 600 | 609.6 | 613.0 | +2.0 -0 | 770 | 26 | 44 | 680 | ±1.0 | 3 | 5 | 648 | 654 | +2.5 -0 | 715 | 20 | 27 | |||||

| 26 | 650 | 660.4 | 664.0 | 825 | 26 | 48 | 735 | 3 | 5 | 702 | +2.5 -0 | 708 | 770 | 24 | 27 | |||||||

| 28 | 700 | 711.2 | 715.0 | 875 | 26 | 48 | 785 | 3 | 5 | 751 | 758 | 820 | 24 | 27 | ||||||||

| 30 | 750 | 762.0 | 766.0 | 945 | 28 | 52 | ±1.5 | 840 | 3 | 5 | 802 | 810 | 880 | 24 | 33 | |||||||

| 32 | 800 | 812.8 | 817.0 | +2.5 -0 | 995 | 28 | 52 | 890 | 3 | 5 | 854 | +3.0 -0 | 862 | +3.0 -0 | 930 | 24 | 33 | |||||

| 34 | 850 | 863.6 | 868.0 | 1045 | +2.5 -0 | 28 | 54 | 940 | 3 | 5 | 904 | 912 | 980 | ±1.0 | 24 | 33 | ||||||

| 36 | 900 | 914.4 | 919.0 | 1095 | 30 | 56 | 990 | 3 | 5 | 956 | 964 | 1030 | 24 | 33 | ||||||||

| 40 | 1000 | 1016.0 | 1021.0 | +3.0 -0 | 1195 | 32 | 60 | 1090 | ±1.2 | 3 | 5 | 1058 | +3.5 -0 | 1066 | +3.5 -0 | 1130 | 28 | 33 | ||||

| 44 | 1100 | 1117.6 | 1123.0 | 1305 | 32 | 1200 | 3 | 1240 | 28 | 33 | ||||||||||||

| 48 | 1200 | 1219.2 | 1224.0 | 1420 | 34 | 1305 | 3 | 1350 | 32 | 33 | ||||||||||||

| 54 | 1350 | 1371.6 | 1377.0 | 1575 | +3.0 -0 | 34 | 1460 | 3 | 1505 | ±1.5 | 32 | 33 | ||||||||||

| 60 | 1500 | 1524.0 | 1529.0 | 1730 | 36 | 1615 | 3 | 1660 | 36 | 33 | ||||||||||||

JIS 10K Blind Flange Dimensions

| Pipe | Pipe | Bo | D | t | T | G | f | r | H | X | C | Holes | Bolt Dia. | |||||||||

| inch | mm | |||||||||||||||||||||

| 3/8 | 10 | 17.3 | 17.8 | +0.5 -0 | 90 | +1.0 -0 | 12 | +1.0 | 16 | ±1.0 | 48 | ±0.8 | 1 | 4 | 26 | +1.0 -0 | 28 | +1.0 -0 | 65 | ±0.5 | 4 | 15 |

| 1/2 | 15 | 21.7 | 22.2 | 95 | 12 | 16 | 52 | 1 | 4 | 30 | 32 | 70 | 4 | 15 | ||||||||

| 3/4 | 20 | 27.2 | 27.7 | 100 | 14 | 20 | 58 | 1 | 4 | 38 | 42 | 75 | 4 | 15 | ||||||||

| 1 | 25 | 34.0 | 34.5 | 125 | 14 | 20 | 70 | 1 | 4 | 46 | 50 | 90 | 4 | 19 | ||||||||

| 1-1/4 | 32 | 42.7 | 43.2 | 135 | 16 | 22 | 80 | 2 | 5 | 56 | 60 | 100 | 4 | 19 | ||||||||

| 1-1/2 | 40 | 48.6 | 49.1 | 140 | 16 | 24 | 85 | 2 | 5 | 62 | 66 | 105 | 4 | 19 | ||||||||

| 2 | 50 | 60.5 | 61.1 | 155 | 16 | 24 | 100 | 2 | 5 | 76 | 80 | 120 | 8 | 19 | ||||||||

| 2-1/2 | 65 | 76.3 | 77.1 | 175 | 18 | 26 | 120 | 2 | 5 | 94 | 98 | 140 | 8 | 19 | ||||||||

| 3 | 80 | 89.1 | 90.0 | 200 | 20 | 28 | 135 | 2 | 6 | 108 | 112 | 160 | 8 | 23 | ||||||||

| 3-1/2 | 90 | 101.6 | 102.6 | +1.0 -0 | 210 | 20 | 30 | 145 | 2 | 6 | 120 | 124 | 170 | 8 | 23 | |||||||

| 4 | 100 | 114.3 | 115.4 | 225 | 22 | +1.5 -0 | 34 | 160 | 2 | 6 | 134 | 138 | 185 | 8 | 23 | |||||||

| 5 | 125 | 139.8 | 141.2 | 270 | 22 | 34 | 195 | 2 | 6 | 164 | 170 | 225 | 8 | 25 | ||||||||

| 6 | 150 | 165.2 | 166.6 | 305 | +1.5 -0 | 24 | 38 | 230 | ±0.9 | 2 | 6 | 196 | 202 | 260 | ±0.6 | 12 | 25 | |||||

| 7 | 175 | 190.7 | 192.1 | 325 | 26 | 40 | 250 | 2 | 6 | 216 | 222 | +1.5 -0 | 280 | 12 | 25 | |||||||

| 8 | 200 | 216.3 | 218.0 | 350 | 26 | 40 | 275 | 2 | 6 | 244 | +1.5 -0 | 252 | 305 | 12 | 25 | |||||||

| 9 | 225 | 241.8 | 243.7 | 385 | 26 | 40 | 325 | 2 | 6 | 266 | 272 | 335 | 12 | 27 | ||||||||

| 10 | 250 | 267.4 | 269.5 | 430 | 28 | 44 | 345 | 2 | 6 | 304 | 312 | 380 | 12 | 27 | ||||||||

| 12 | 300 | 318.5 | 321.0 | 480 | 30 | 48 | 395 | 3 | 8 | 354 | 364 | 430 | 16 | 27 | ||||||||

| 14 | 350 | 355.6 | 358.1 | 540 | 34 | 52 | ±1.5 | 440 | 3 | 8 | 398 | 408 | 480 | 16 | 33 | |||||||

| 16 | 400 | 406.4 | 409.0 | +1.5 -0 | 605 | +2.0 -0 | 38 | 60 | 495 | 3 | 10 | 446 | 456 | +2.0 -0 | 540 | 16 | 33 | |||||

| 18 | 450 | 457.2 | 460.0 | 675 | 40 | 64 | 560 | 3 | 10 | 504 | +2.0 -0 | 514 | 605 | ±0.8 | 20 | 33 | ||||||

| 20 | 500 | 508.0 | 511.0 | 730 | 42 | 68 | 615 | 3 | 10 | 558 | 568 | 660 | 20 | 33 | ||||||||

| 22 | 550 | 558.8 | 562.0 | 795 | 44 | 70 | 670 | ±1.0 | 3 | 10 | 612 | 622 | 720 | 20 | 39 | |||||||

| 24 | 600 | 609.6 | 613.0 | +2.0 -0 | 845 | 46 | 74 | 720 | 3 | 10 | 666 | +2.5 -0 | 676 | +2.5 -0 | 770 | 24 | 39 | |||||

| 26 | 650 | 660.4 | 664.0 | 895 | 48 | 77 | 770 | 5 | 10 | 704 | 726 | 820 | 24 | 39 | ||||||||

| 28 | 700 | 711.2 | 715.0 | 960 | 50 | 80 | 820 | 5 | 10 | 754 | 776 | 875 | 24 | 42 | ||||||||

| 30 | 750 | 762.0 | 766.0 | 1020 | +2.5 -0 | 52 | +2.0 -0 | 83 | 880 | 5 | 10 | 806 | 832 | 935 | 24 | 42 | ||||||

| 32 | 800 | 812.8 | 817.0 | +2.5 -0 | 1085 | 54 | 86 | 930 | 5 | 10 | 865 | +3.0 -0 | 885 | +3.0 -0 | 990 | ±1.0 | 24 | 48 | ||||

| 34 | 850 | 863.6 | 868.0 | 1135 | 56 | 89 | 980 | 5 | 10 | 916 | 936 | 1040 | 24 | 48 | ||||||||

| 36 | 900 | 914.4 | 919.0 | 1185 | 58 | 93 | 1030 | ±1.2 | 5 | 10 | 968 | 986 | 1090 | 28 | 48 | |||||||

| 40 | 1000 | 1016.0 | 1021.0 | +3.0 -0 | 1320 | 62 | 99 | 1140 | 5 | 12 | 1070 | +3.5 -0 | 1098 | +3.5 -0 | 1210 | 28 | 56 | |||||

| 44 | 1100 | 1117.6 | 1123.0 | 1420 | 66 | 105 | ±2.0 | 1240 | 5 | 12 | 1180 | 1200 | 1310 | 32 | 56 | |||||||

| 48 | 1200 | 1219.2 | 1225.0 | 1530 | +3.0 -0 | 70 | 112 | 1350 | 5 | 12 | 1282 | 1302 | 1420 | ±1.5 | 32 | 56 | ||||||

| 52 | 1300 | 1320.8 | 1326.0 | 1645 | 74 | 1450 | 5 | 1530 | 32 | 62 | ||||||||||||

| 54 | 1350 | 1371.6 | 1377.0 | 1700 | 76 | 1510 | 5 | 1590 | 32 | 62 | ||||||||||||

| 56 | 1400 | 1422.4 | 1428.0 | 1755 | 78 | 1560 | 5 | 1640 | 36 | 62 | ||||||||||||

| 60 | 1500 | 1524.0 | 1529.0 | 1865 | 80 | 1670 | 5 | 1750 | 36 | 62 | ||||||||||||

JIS 16K Blind Flange Dimensions

| Pipe | Pipe | Bo | D | t | T | G | f | r | H | X | C | Holes | Bolt Dia. | |||||||||

| inch | mm | |||||||||||||||||||||

| 3/8 | 10 | 17.3 | 17.8 | +0.5 -0 | 90 | +1.0 -0 | 12 | +1.0 -0 | ±1.0 | 48 | ±0.8 | 1 | +1.5 -0 | +1.5 -0 | 65 | ±0.5 | 4 | 15 | ||||

| 1/2 | 15 | 21.7 | 22.2 | 95 | 12 | 52 | 1 | 70 | 4 | 15 | ||||||||||||

| 3/4 | 20 | 27.2 | 27.7 | 100 | 14 | 58 | 1 | 75 | 4 | 15 | ||||||||||||

| 1 | 25 | 34.0 | 34.5 | 125 | 14 | 70 | 1 | 90 | 4 | 19 | ||||||||||||

| 1-1/4 | 32 | 42.7 | 43.2 | 135 | 16 | 80 | 2 | 100 | 4 | 19 | ||||||||||||

| 1-1/2 | 40 | 48.6 | 49.1 | 140 | 16 | 85 | 2 | 105 | 4 | 19 | ||||||||||||

| 2 | 50 | 60.5 | 61.1 | 155 | 16 | 100 | 2 | 120 | 4 | 19 | ||||||||||||

| 2-1/2 | 65 | 76.3 | 77.1 | 175 | 18 | 120 | 2 | 140 | 4 | 19 | ||||||||||||

| 3 | 80 | 89.1 | 90.0 | 185 | 18 | 130 | 2 | 150 | 8 | 19 | ||||||||||||

| 3-1/2 | 90 | 101.6 | 102.6 | +1.0 -0 | 195 | 18 | 140 | 2 | 160 | 8 | 19 | |||||||||||

| 4 | 100 | 114.3 | 115.4 | 210 | 18 | 155 | 2 | 175 | 8 | 19 | ||||||||||||

| 5 | 125 | 139.8 | 141.2 | 250 | 20 | 185 | 2 | 210 | 8 | 23 | ||||||||||||

| 6 | 150 | 165.2 | 166.6 | 280 | 22 | +1.5 -0 | 215 | 2 | 240 | 8 | 23 | |||||||||||

| 7 | 175 | 190.7 | 192.1 | 305 | +1.5 -0 | 22 | 32 | 240 | ±0.9 | 2 | 6 | 208 | 212 | 265 | ±0.6 | 12 | 23 | |||||

| 8 | 200 | 216.3 | 218.0 | 330 | 22 | 32 | 265 | 2 | 6 | 234 | 238 | 290 | 12 | 23 | ||||||||

| 9 | 225 | 241.8 | 243.7 | 350 | 22 | 34 | 285 | 2 | 6 | 260 | 264 | 310 | 12 | 23 | ||||||||

| 10 | 250 | 267.4 | 269.5 | 400 | 24 | 36 | 325 | 2 | 6 | 288 | 292 | 355 | 12 | 25 | ||||||||

| 12 | 300 | 318.5 | 321.0 | 445 | 24 | 38 | 370 | 3 | 6 | 340 | 346 | 400 | 16 | 25 | ||||||||

| 14 | 350 | 355.6 | 358.1 | 490 | 26 | 42 | 415 | 3 | 6 | 380 | 386 | 445 | 16 | 25 | ||||||||

| 16 | 400 | 406.4 | 409.0 | +1.5 -0 | 560 | 28 | 44 | 475 | 3 | 6 | 436 | 442 | 510 | 16 | 27 | |||||||

| 18 | 450 | 457.2 | 460.0 | 620 | +2.0 -0 | 30 | 48 | 530 | 3 | 6 | 496 | +2.0 -0 | 502 | +2.0 -0 | 565 | ±0.8 | 20 | 27 | ||||

| 20 | 500 | 508.0 | 511.0 | 675 | 30 | 48 | 585 | 3 | 6 | 548 | 554 | 620 | 20 | 27 | ||||||||

| 22 | 550 | 558.8 | 562.0 | 745 | 32 | 52 | ±1.5 | 640 | 3 | 6 | 604 | 610 | 680 | 20 | 33 | |||||||

| 24 | 600 | 609.6 | 613.0 | +2.0 -0 | 795 | 32 | 52 | 690 | ±1.0 | 3 | 6 | 656 | +2.5 -0 | 662 | +2.5 -0 | 730 | 24 | 33 | ||||

| 26 | 650 | 660.4 | 664.0 | 845 | 34 | 56 | 740 | 3 | 6 | 706 | 712 | 780 | 24 | 33 | ||||||||

| 28 | 700 | 711.2 | 715.0 | 905 | 34 | 58 | 800 | 3 | 6 | 762 | 770 | 840 | 24 | 33 | ||||||||

| 30 | 750 | 762.0 | 766.0 | 970 | 36 | 62 | 855 | 3 | 6 | 816 | 824 | 900 | 24 | 33 | ||||||||

| 32 | 800 | 812.8 | 817.0 | +2.5 -0 | 1020 | +2.5 -0 | 36 | 64 | 905 | 3 | 6 | 868 | +3.0 -0 | 876 | +3.0 -0 | 950 | 28 | 33 | ||||

| 34 | 850 | 863.6 | 868.0 | 1070 | 36 | 66 | 955 | 3 | 6 | 920 | 928 | 1000 | ±1.0 | 28 | 33 | |||||||

| 36 | 900 | 914.4 | 919.0 | 1120 | 38 | 70 | 1005 | ±1.2 | 3 | 6 | 971 | 979 | 1050 | 28 | 33 | |||||||

| 40 | 1000 | 1016.0 | 1021.0 | +3.0 -0 | 1235 | 40 | 74 | 1110 | 3 | 6 | 1073 | +3.5 -0 | 1081 | +3.5 -0 | 1160 | 28 | 39 | |||||

| 44 | 1100 | 1117.6 | 1123.0 | 1345 | 42 | 78 | 1220 | 3 | 8 | 1175 | 1185 | 1270 | 28 | 39 | ||||||||

| 48 | 1200 | 1219.2 | 1224.0 | 1465 | 44 | 82 | 1325 | 3 | 8 | 1278 | 1290 | 1380 | ±1.5 | 32 | 39 | |||||||

| 54 | 1350 | 1371.6 | 1377.0 | 1630 | +3.0 -0 | 48 | 88 | 1480 | 3 | 8 | 1432 | 1450 | 1540 | 36 | 45 | |||||||

| 60 | 1500 | 1524.0 | 1529.0 | 1795 | 50 | 90 | 1635 | 3 | 8 | 1585 | 1600 | 1700 | 40 | 45 | ||||||||

Blind Flange Weight & Blind Flange Pressure Ratings

| Blind Flange Weights by Pressure Class and Size | ||||||||||||||||||

| Pipe Size | 150 # | 300 # | 600 # | 900 # | 1500 # | 2500 # | ||||||||||||

| WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | |

| 1/2″ | 2 | 1 | 1 | 2 | 1 | 1 | 2 | 2 | 2 | SEE 1500 # WEIGHTS | 5 | 4 | 4 | 7 | 7 | 7 | ||

| 3/4″ | 2 | 2 | 2 | 3 | 3 | 3 | 4 | 3 | 3 | SEE 1500 # WEIGHTS | 6 | 5 | 6 | 8 | 8 | 8 | ||

| 1″ | 3 | 2 | 2 | 4 | 3 | 3 | 4 | 4 | 4 | SEE 1500 # WEIGHTS | 9 | 8 | 8 | 12 | 11 | 11 | ||

| 1 1/2″ | 4 | 3 | 3 | 7 | 6 | 6 | 8 | 7 | 8 | SEE 1500 # WEIGHTS | 13 | 12 | 13 | 25 | 22 | 23 | ||

| 2″ | 6 | 5 | 5 | 9 | 7 | 8 | 12 | 9 | 10 | SEE 1500 # WEIGHTS | 25 | 25 | 25 | 42 | 37 | 39 | ||

| 2 1/2″ | 8 | 7 | 7 | 12 | 10 | 12 | 18 | 13 | 15 | SEE 1500 # WEIGHTS | 36 | 36 | 35 | 52 | 55 | 56 | ||

| 3″ | 10 | 8 | 9 | 15 | 13 | 16 | 23 | 16 | 20 | 31 | 26 | 29 | 48 | 48 | 48 | 94 | 83 | 86 |

| 4″ | 15 | 13 | 17 | 25 | 22 | 27 | 42 | 37 | 41 | 53 | 53 | 54 | 73 | 73 | 73 | 145 | 125 | 130 |

| 5″ | 19 | 15 | 20 | 32 | 28 | 35 | 68 | 63 | 68 | 86 | 83 | 87 | 130 | 130 | 140 | 245 | 210 | 225 |

| 6″ | 24 | 19 | 26 | 42 | 39 | 50 | 81 | 80 | 86 | 110 | 110 | 115 | 165 | 165 | 160 | 380 | 325 | 345 |

| 8″ | 39 | 30 | 45 | 67 | 58 | 81 | 120 | 115 | 140 | 175 | 170 | 200 | 275 | 260 | 300 | 580 | 485 | 530 |

| 10″ | 52 | 43 | 70 | 91 | 81 | 124 | 190 | 170 | 230 | 260 | 245 | 290 | 455 | 435 | 510 | 1075 | 930 | 1025 |

| 12″ | 80 | 64 | 110 | 140 | 115 | 185 | 225 | 200 | 295 | 325 | 325 | 415 | 690 | 580 | 690 | 1525 | 1100 | 1300 |

| 14″ | 110 | 90 | 140 | 180 | 165 | 250 | 280 | 230 | 355 | 400 | 400 | 520 | 940 | NA | 975 | NA | NA | NA |

| 16″ | 140 | 98 | 180 | 250 | 190 | 295 | 390 | 330 | 495 | 495 | 425 | 600 | 1250 | NA | 1300 | NA | NA | NA |

| 18″ | 150 | 130 | 220 | 320 | 250 | 395 | 475 | 400 | 630 | 680 | 600 | 850 | 1625 | NA | 1750 | NA | NA | NA |

| 20″ | 180 | 165 | 285 | 400 | 315 | 505 | 590 | 510 | 810 | 830 | 730 | 1075 | 2050 | NA | 2225 | NA | NA | NA |

| 22″ | 225 | 185 | 355 | 465 | 370 | 640 | 720 | 590 | 1000 | NA | NA | NA | NA | NA | NA | NA | NA | NA |

| 24″ | 260 | 220 | 430 | 580 | 475 | 790 | 830 | 730 | 1250 | 1500 | 1400 | 2025 | 3325 | NA | 3625 | NA | NA | NA |

Dimensional Tolerances of ASME B16.5 Blind Flanges

| Outside Diameter ≤ 24 = 1.6 mm | > 24 = ± 3.2 mm |

Inside Diameter not applicable |

|---|---|

| Diameter of Contact Face 1.6 mm Raised Face = ± 0.8 mm 6.35 mm Raised Face, Tongue & Groove / Male-Female = ± 0.4 mm |

Outside Diameter of Hub ≤ 12 = + 2.4 mm / – 1.6 mm | ≥ 14 = ± 3.2 mm |

| Diameter of Counterbore not applicable |

Drilling Bolt Circle = 1.6 mm | Bolt Hole Spacing = ± 0.8 mm Eccentricity of Bolt Circle with Respect to Facing ≤ 2½ = 0.8 mm max. | ≥ 3 = 1.6 mm max. |

| Thickness ≤ 18 = + 3.2 mm / – 0 | ≥ 20 = + 4.8 mm / – 0 |

Length thru Hub ≤ 18 = + 3.2 mm / – 0.8 mm | ≥ 20 = + 4.8 mm / – 1.6 mm |

Applications and Uses of Blind Flanges

- Spectacle Blinds: Commonly used for transporting materials.

- Stainless Steel Spectacle Blinds: Used in the automotive industry.

- Spectacle Blinds: Applied in homes and buildings.

- SS Spectacle Blinds: Utilized in sewerage systems and industrial water lines.

- Carbon Steel Spectacle Blinds: Employed in heating and air-conditioning systems.

- Spectacle Blinds: Used in plumbing applications.

- Alloy Spectacle Blinds: Used in the food processing industry.

- Spectacle Blinds: Applied in the paper and pulp industry.

- Spectacle Blinds: Utilized in the food industry.

Kaizen Steel Industries Export to

Burundi, Comoros, Djibouti, Eritrea, Ethiopia, Kenya, Madagascar, Malawi, Mauritius, Mayotte, Mozambique, Reunion, Rwanda, Seychelles, Somalia, Tanzania, United Republic of Uganda, Zambia, Zimbabwe, Angola, Cameroon, Central African Republic, Chad, Congo (Brazzaville), Congo, Democratic Republic of the Equatorial Guinea, Gabon, Sao Tome and Principe, Algeria, Egypt, Libyan Arab Jamahiriya, Morroco, South Sudan, Sudan, Tunisia, Western Sahara, Botswana, Lesotho, Namibia, South Africa, Swaziland, Benin, Burkina Faso, Cape Verde, Cote d\\’Ivoire (Ivory Coast), Gambia, Ghana, Guinea, Guinea-Bissau, Liberia, Mali, Mauritania, Niger, Nigeria, Saint Helena, Senegal, Sierra Leone, Togo

Anguilla, Antigua and Barbuda, Aruba, Bahamas, Barbados, Bonaire, Saint Eustatius and Saba, British Virgin Islands, Cayman Islands, Cuba, Curaçao, Dominica, Dominican Republic, Grenada, Guadeloupe, Haiti, Jamaica, Martinique, Monserrat, Puerto Rico, Saint-Barthélemy, St. Kitts and Nevis, Saint Lucia, Saint Martin, Saint Vincent and the Grenadines, Sint Maarten, Trinidad and Tobago, Turks and Caicos Islands, Virgin Islands (US), Belize, Costa Rica, El Salvador, Guatemala, Honduras, Mexico, Nicaragua, Panama, Argentina, Bolivia, Brazil, Chile, Colombia, Ecuador, Falkland Islands (Malvinas), French Guiana, Guyana, Paraguay, Peru, Suriname, Uruguay, Venezuela, Bermuda, Canada, Greenland, Saint Pierre and Miquelon, United States

Afghanistan, Armenia, Azerbaijan, Bangladesh, Bhutan, Brunei Darussalam, Cambodia, China, Georgia, Hong Kong, India, Indonesia, Japan, Kazakhstan, South Korea, Kyrgyzstan, Laos, Macao, Malaysia, Maldives, Mongolia, Myanmar (ex-Burma), Nepal, Phillipines, Singapore, Sri Lanka (ex-Ceilan), Taiwan, Tajikistan, Thailand, Timor Leste (West), Turkmenistan, Uzbekistan, Vietnam

Albania, Andorra, Belarus, Bosnia, Croatia, European Union, Faroe Islands, Gibraltar, Guerney and Alderney, Iceland, Jersey, Kosovo, Liechtenstein, Macedonia, Man, Island of Moldova, Monaco, Montenegro, Norway, Russia, San Marino, Serbia, Svalbard and Jan Mayen Islands, Switzerland, Turkey, Ukraine, Vatican City State (Holy See)

Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, United Kingdom

Bahrain, Iraq, Iran, Israel, Jordan, Kuwait, Lebanon, Oman, Palestine, Qatar, Saudi Arabia, Syria, United Arab Emirates, Yemen