ASME B16.9 Eccentric Reducer Supplier

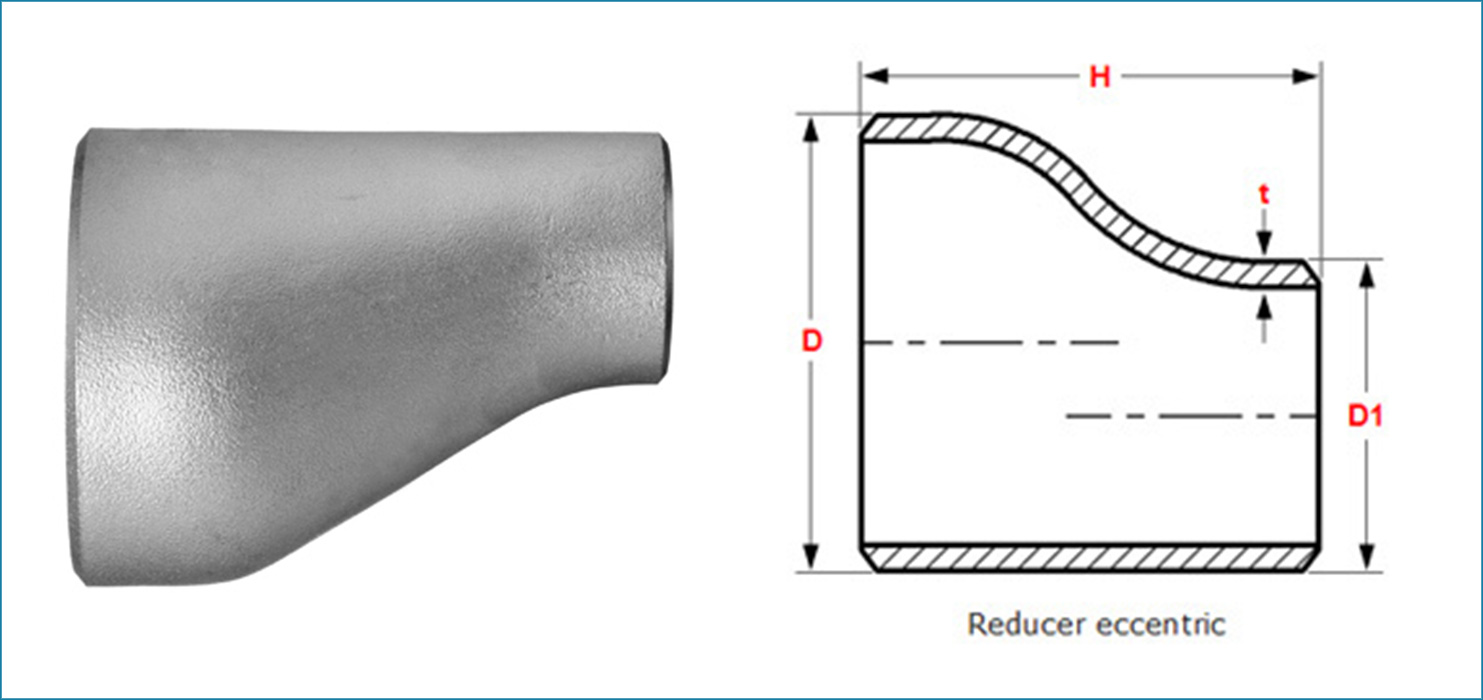

Eccentric reducers are essential components used to connect pipes of differing diameters in horizontal piping systems, featuring a flat bottom face on one side to ensure a smooth and consistent flow.

Our eccentric reducers are available in a range of materials including stainless steel, carbon steel, alloy steel, high-performance nickel alloys, and duplex steel. Stainless steel reducers, particularly those made from grade 316, offer exceptional resistance to corrosion and are ideal for marine environments and high-temperature applications. Carbon steel reducers provide robust performance for general applications, while alloy steel reducers excel in extreme conditions.

We manufacture our eccentric reducers in accordance with international standards such as ANSI / ASME B16.9. For more information on dimensions, pricing, and available stock, please contact us or request a quote.

At our factory, we manufacture a variety of Eccentric Reducers adhering to different dimensions and standards including ANSI / ASME B16.9, ASME B16.28, MSS-SP-43, DIN 2650, 2615, 2616, 2617, JIS B2311, B2312, B2313, EN 10253-1, and EN 10253-2. Our SS Eccentric Reducers are available in multiple wall thicknesses or schedules, such as SCH5, SCH10, SCH20, SCH30, SCH STD, SCH40, SCH60, SCH XS, SCH80, SCH100, SCH120, SCH140, SCH160, and XXS. We offer a range of types including Seamless, Welded, and Fabricated.

The ASME B16.9 Eccentric Reducers we produce offer numerous benefits including high tensile strength, dimensional accuracy, durability, resistance to temperature extremes, and a superior finish. Eccentric reducers made from duplex stainless steel or nickel-based alloys like Monel and Inconel exhibit excellent resistance to chloride-ion stress corrosion cracking. Carbon Steel Eccentric Reducers also show good resistance to oxidizing environments, while Incoloy reducers are highly resistant to oxidation and chemical corrosion. Additionally, most reducers in our stock have a low creep rate under high stress at elevated temperatures, and those processed with suitable heat treatments have high stress-rupture effectiveness.

As a leading manufacturer, distributor, and supplier of high-quality steel products, including various sizes and shapes of Eccentric Reducers, we ensure that our products meet ASTM, ASME, DIN, and other international standards. For special cases, we can tailor orders to meet customized requirements.

- Seamless pipes: Outside diameter from ½” (21.34 mm) to 24″ (609.60 mm)

- Welded pipes: Outside diameter from 26″ (660.00 mm) to 72″ (1829.00 mm)

B16.9 Eccentric Reducer Specification

| Specifications | ASME B16.9 Eccentric Reducer |

|---|---|

| Eccentric Reducer Schedule 80 Pipe Fittings size | Seamless Butt Weld Fittings: 1/2″ – 10″ Welded Butt Weld Fittings: 1/2″ – 48″ |

| Eccentric Buttweld Reducer Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Eccentric Reducer b16.9 Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Eccentric Pipe Reducer Types | Seamless / ERW / Welded / Fabricated Pipe Fittings |

| Eccentric Reducer Schedule 40 Type | DN15-DN1200 |

| Connection | Welding |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom Pipe Fittings |

| Stainless Steel Eccentric Reducer B16.9 Size Range | ½” NB to 24″ NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) |

| Eccentric Buttweld Reducer Fittings | Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D, 5D, 6D, 7D-40D. Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO |

| Manufacturing process for CS Eccentric Reducer | Push, Press, Forge, Cast, etc. |

| Eccentric Pipe Reducer Fittings Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Origin & Mills For Carbon Steel Eccentric Reducer Material | Japanese, Indian, USA, Korean, European, Ukraine, Russian |

| Key markets and industries for SS Eccentric Reducer |

|

| Eccentric Reducer Schedule 40 Application |

|

| Eccentric Reducer Material & Grades |

|

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

ASME B16.9 Eccentric Reducer Types

ASME B16.9 Eccentric Reducer SCH 10 ANSI B16.9 ASTM A234 WPB Eccentric Reducer Pipe Fitting

Eccentric Reducer Schedule 40 ANSI B16.9, BW, ASTM A234 WP5 Seamless Eccentric Reducer

SS Eccentric Reducer Sch 80 A234 WPB, ANSI B16.9, Black Reducer, Eccentric, 10 X 6 Inch, BW

ASME B16.9 CS Eccentric Reducer 8×4 Inch, SCH 40, SS A403 WP304 Eccentric Reducer, BW

MSS SP43 MS Eccentric Reducer ASTM A234 WPB, Butt Weld ECC Reducer, ASME B16.9

Buttweld Eccentric Reducer Schedule 40 Buttweld, ASTM A234 WP11 Eccentric Reducer

Eccentric Reducer Dimensions

| Code RCD REISO | Ø BIG | Ø SMALL | HEIGHT H mm | THEORETICAL WEIGHT KG | ||||

|---|---|---|---|---|---|---|---|---|

| DN | D mm | Thickness S mm | DN | d mm | Thickness s mm | |||

| 27 21 | 3/4 | 26.9 | 2.3 | 1/2 | 21.3 | 2.0 | 38 | 0.08 |

| 33 21 | 1 | 33.7 | 2.6 | 1/2 | 21.3 | 2.0 | 50 | 0.09 |

| 33 27 | 3/4 | 26.9 | 2.3 | 0.09 | ||||

| 42 21 | 1″1/4 | 42.4 | 2.6 | 1/2 | 21.3 | 2.0 | 50 | 0.12 |

| 42 27 | 3/4 | 26.9 | 2.3 | 0.13 | ||||

| 42 33 | 1 | 33.7 | 2.6 | 0.14 | ||||

| *48 21 | 1″1/2 | 48.3 | 2.6 | 1/2 | 21.3 | 2.0 | 64 | 0.18 |

| 48 27 | 3/4 | 26.9 | 2.3 | 0.19 | ||||

| 48 33 | 1 | 33.7 | 2.6 | 0.20 | ||||

| 48 42 | 1″1/4 | 42.4 | 2.6 | 0.20 | ||||

| 60 27 | 2 | 60.3 | 2.9 | 3/4 | 26.9 | 2.3 | 76 | 0.30 |

| 60 33 | 1 | 33.7 | 2.6 | 0.31 | ||||

| 60 42 | 1″1/4 | 42.4 | 2.6 | 0.32 | ||||

| 60 48 | 1″1/2 | 48.3 | 2.6 | 0.33 | ||||

| 76 33 | 2″1/2 | 76.1 | 2.9 | 1 | 33.7 | 2.6 | 90 | 0.40 |

| 76 42 | 1″1/4 | 42.4 | 2.6 | 0.47 | ||||

| 76 48 | 1″1/2 | 48.3 | 2.6 | 0.48 | ||||

| 76 60 | 2 | 60.3 | 2.6 | 0.49 | ||||

| 89 42 | 3 | 88.9 | 3.2 | 1″1/4 | 42.4 | 2.6 | 90 | 0.55 |

| 89 48 | 1″1/2 | 48.3 | 2.6 | 0.61 | ||||

| 89 60 | 2 | 60.3 | 2.9 | 0.62 | ||||

| 89 76 | 2″1/2 | 76.1 | 2.9 | 0.63 | ||||

| 114 48 | 4 | 114.3 | 3.6 | 1″1/2 | 48.3 | 2.6 | 100 | 0.85 |

| 114 60 | 2 | 60.3 | 2.9 | 0.98 | ||||

| 114 76 | 2″1/2 | 76.1 | 2.9 | 1.00 | ||||

| 114 89 | 3 | 88.9 | 3.2 | 1.02 | ||||

| 139 60 | 5 | 139.7 | 4.0 | 2 | 60.3 | 2.9 | 127 | 1.60 |

| 139 76 | 2″1/2 | 76.1 | 2.9 | 1.70 | ||||

| 139 89 | 3 | 88.9 | 3.2 | 1.74 | ||||

| 139 114 | 4 | 114.3 | 3.6 | 1.76 | ||||

| *168 76 | 6 | 168.3 | 4.5 | 2″1/2 | 76.1 | 2.9 | 140 | 2.60 |

| 168 89 | 3 | 88.9 | 3.2 | 2.70 | ||||

| 168 114 | 4 | 114.3 | 3.6 | 2.82 | ||||

| 168 139 | 5 | 139.7 | 4.0 | 2.94 | ||||

| 219 114 | 8 | 219.1 | 6.3 | 4 | 114.3 | 3.6 | 152 | 5.03 |

| 219 139 | 5 | 139.7 | 4.0 | 5.12 | ||||

| 219 168 | 6 | 168.3 | 4.5 | 5.18 | ||||

| *273 114 | 10 | 273.0 | 6.3 | 4 | 114.3 | 3.6 | 178 | 7.00 |

| *273 139 | 5 | 139.7 | 4.0 | 7.20 | ||||

| 273 168 | 6 | 168.3 | 4.5 | 7.40 | ||||

| 273 219 | 8 | 219.1 | 6.3 | 7.55 | ||||

| 323 168 | 12 | 323.9 | 7.1 | 6 | 168.3 | 4.5 | 203 | 11.00 |

| 323 219 | 8 | 219.1 | 6.3 | 11.10 | ||||

| 323 273 | 10 | 273 | 6.3 | 11.20 | ||||

Eccentric Reducer Weight Chart

Nominal Diameter | Outside Diameter | End to End | ||

| D1*D2 | ||||

| DN | NPS | Series A | Series B | H |

| 20*15 | 3/4*1/2 | 26.9*21.3 | 25*18 | 38 |

| 20*10 | 3/4*3/8 | 26.9*17.3 | 25*14 | 38 |

| 25*20 | 1*3/4 | 33.7*26.9 | 32*25 | 51 |

| 25*15 | 1*1/2 | 33.7*21.3 | 32*18 | 51 |

| 32*25 | 1.1/4*1 | 42.4*33.7 | 38*32 | 51 |

| 32*20 | 1.1/4*3/4 | 42.4*26.9 | 38*25 | 51 |

| 32*15 | 1.1/4*1/2 | 42.4*21.3 | 38*18 | 51 |

| 40*32 | 1.1/2*1.1/4 | 48.3*42.4 | 45*38 | 64 |

| 40*25 | 1.1/2*1 | 48.3*33.7 | 45*32 | 64 |

| 40*20 | 1.1/2*3/4 | 48.3*26.9 | 45*25 | 64 |

| 40*15 | 1.1/2*1/2 | 48.3*21.3 | 45*18 | 64 |

| 50*40 | 2*1.1/2 | 60.3*48.3 | 57*45 | 76 |

| 50*32 | 2*1.1/4 | 60.3*42.4 | 57*38 | 76 |

| 50*25 | 2*1 | 60.3*33.7 | 57*32 | 76 |

| 50*20 | 2*3/4 | 60.3*26.9 | 57*25 | 76 |

| 65*50 | 2.1/2*2 | 73.0*60.3 | 76*57 | 89 |

| 65*40 | 2.1/2*1.1/2 | 73.0*48.3 | 76*45 | 89 |

| 65*32 | 2.1/2*1.1/4 | 73.0*42.4 | 76*38 | 89 |

| 65*25 | 2.1/2*1 | 73.0*33.7 | 76*32 | 89 |

| 80*65 | 3*2.1/2 | 88.9*73.0 | 89*76 | 89 |

| 80*50 | 3*2 | 88.9*60.3 | 89*57 | 89 |

| 80*40 | 3*1.1/2 | 88.9*48.3 | 89*45 | 89 |

| 80*32 | 3*1.1/4 | 88.9*42.4 | 89*38 | 89 |

| 90*80 | 3.1/2*3 | 101.6*88.9 | – | 102 |

| 90*65 | 3.1/2*2.1/2 | 101.6*73.0 | – | 102 |

| 90*50 | 3.1/2*2 | 101.6*60.3 | – | 102 |

| 90*40 | 3.1/2*1.1/2 | 101.6*48.3 | – | 102 |

| 90*32 | 3.1/2*1.1/4 | 101.6*42.4 | – | 102 |

| 100*90 | 4*3.1/2 | 114.3*101.6 | – | 102 |

| 100*80 | 4*3 | 114.3*88.9 | 108*89 | 102 |

| 100*65 | 4*2.1/2 | 114.3*73.0 | 108*76 | 102 |

| 100*50 | 4*2 | 114.3*60.3 | 108*57 | 102 |

| 100*40 | 4*1.1/2 | 114.3*48.3 | 108*45 | 102 |

| 125*100 | 5*4 | 141.3*114.3 | 133*108 | 127 |

| 125*90 | 5*3.1/2 | 141.3*101.6 | – | 127 |

| 125*80 | 5*3 | 141.3*88.9 | 133*89 | 127 |

| 125*65 | 5*2.1/2 | 141.3*73.0 | 133*76 | 127 |

| 125*50 | 5*2 | 141.3*60.3 | 133*57 | 127 |

| 150*125 | 6*5 | 168.3*141.3 | 159*133 | 140 |

| 150*100 | 6*5 | 168.3*114.3 | 159*108 | 140 |

| 150*90 | 6*3.1/2 | 168.3*101.6 | – | 140 |

| 150*80 | 6*3 | 168.3*88.9 | 159*89 | 140 |

| 150*65 | 6*2.1/2 | 168.3*73.0 | 159*76 | 140 |

| 200*150 | 8*6 | 219.1*168.3 | 219*159 | 152 |

| 200*125 | 8*5 | 219.1*141.3 | 219*133 | 152 |

| 200*100 | 8*4 | 219.1*114.3 | 219*108 | 152 |

| 200*90 | 8*3.1/2 | 219.1*101.6 | – | 152 |

| 250*200 | 10*8 | 273.0*219.1 | 273*219 | 178 |

| 250*150 | 10*6 | 273.0*168.3 | 273*159 | 178 |

| 250*125 | 10*5 | 273.0*141.3 | 273*133 | 178 |

| 250*100 | 10*4 | 273.0*114.3 | 273*108 | 178 |

| 300*250 | 12*10 | 323.9*273.1 | 325*273 | 203 |

| 300*200 | 12*8 | 323.9*219.1 | 325*219 | 203 |

| 300*150 | 12*6 | 323.9*168.3 | 325*159 | 203 |

| 300*125 | 12*5 | 323.9*141.3 | 325*133 | 203 |

| 350*300 | 14*12 | 355.6*323.9 | 377*325 | 330 |

| 350*250 | 14*10 | 355.6*273.0 | 377*273 | 330 |

| 350*200 | 14*8 | 355.6*219.1 | 377*219 | 330 |

| 350*150 | 14*6 | 355.6*168.3 | 377*159 | 330 |

| 400*350 | 16*14 | 406.4*355.6 | 426*377 | 356 |

| 400*300 | 16*12 | 406.4*323.9 | 426*325 | 356 |

| 400*250 | 16*10 | 406.4*273.0 | 426*273 | 356 |

| 400*200 | 16*8 | 406.4*219.1 | 426*219 | 356 |

| 450*400 | 18*16 | 457*406.4 | 478*426 | 381 |

| 450*350 | 18*14 | 457*355.6 | 478*377 | 381 |

| 450*300 | 18*12 | 457*323.9 | 478*325 | 381 |

| 450*250 | 18*10 | 457*273.0 | 478*273 | 381 |

| 500*450 | 20*18 | 508*457 | 529*478 | 508 |

| 500*400 | 20*16 | 508*406.4 | 529*426 | 508 |

| 500*350 | 20*14 | 508*355.6 | 529*377 | 508 |

| 500*300 | 20*12 | 508*323.9 | 529*325 | 508 |

| 550*500 | 22*20 | 559*508 | – | 508 |

| 550*450 | 22*18 | 559*457 | – | 508 |

| 550*400 | 22*16 | 559×406.4 | – | 508 |

| 550*350 | 22*14 | 559*355.6 | – | 508 |

| 600*550 | 24*22 | 610*559 | – | 508 |

| 600*500 | 24*20 | 610*508 | 630*529 | 508 |

| 600*450 | 24*18 | 610*457 | 630*478 | 508 |

| 600*400 | 24*22 | 610*406.4 | 630*426 | 508 |

| 650*600 | 26*24 | 660*610 | – | 610 |

| 650*550 | 26*22 | 660*559 | – | 610 |

| 650*500 | 26*20 | 660*508 | – | 610 |

| 650*450 | 26*18 | 660*457 | – | 610 |

| 700*650 | 28*26 | 711*660 | – | 610 |

| 700*600 | 28*24 | 711*610 | 720*630 | 610 |

| 700*550 | 28*22 | 711*559 | – | 610 |

| 700*500 | 28*20 | 711*508 | 720*530 | 610 |

| 750*700 | 30*28 | 762*711 | – | 610 |

| 750*650 | 30*26 | 762*660 | – | 610 |

| 750*600 | 30*24 | 762*610 | – | 610 |

| 750*550 | 30*22 | 762*559 | – | 610 |

| 800*750 | 32*30 | 813*762 | – | 610 |

| 800*700 | 32*28 | 813*711 | 820*720 | 610 |

| 800*650 | 32*26 | 813*660 | – | 610 |

| 800*600 | 32*24 | 813*610 | 820*630 | 610 |

| 850*800 | 34*32 | 864*813 | – | 610 |

| 850*750 | 34*30 | 864*762 | – | 610 |

| 850*700 | 34*28 | 864*711 | – | 610 |

| 850*650 | 34*26 | 864*660 | – | 610 |

| 900*850 | 36*34 | 914*864 | – | 610 |

| 900*800 | 36*32 | 914*813 | 920*820 | 610 |

| 900*750 | 36*30 | 914*762 | – | 610 |

| 900*700 | 36*28 | 914*711 | 920*720 | 610 |

| 950*900 | 38*36 | 965*914 | – | 610 |

| 950*850 | 38*34 | 965*864 | – | 610 |

| 950*800 | 38*32 | 965*813 | – | 610 |

| 950*750 | 38*30 | 965*762 | – | 610 |

| 1000*950 | 40*38 | 1016*965 | – | 610 |

| 1000*900 | 40*36 | 1016*914 | 1020*920 | 610 |

| 1000*850 | 40*34 | 1016*864 | – | 610 |

| 1000*800 | 40*32 | 1016*813 | 1020*820 | 610 |

| 1050*1000 | 42*40 | 1067*1016 | – | 610 |

| 1050*950 | 42*38 | 1067*965 | – | 610 |

| 1050*900 | 42*36 | 1067*914 | – | 610 |

| 1050*850 | 42*34 | 1067*864 | – | 610 |

| 1100*1050 | 44*42 | 1118*1067 | – | 610 |

| 1100*1000 | 44*40 | 1118*1016 | 1120*1020 | 610 |

| 1100*950 | 44*38 | 1118*965 | – | 610 |

| 1100*900 | 44*36 | 1118*914 | 1220*920 | 610 |

| 1150*1100 | 46*44 | 1168*1118 | – | 711 |

| 1150*1050 | 46*42 | 1168*1067 | – | 711 |

| 1150*1000 | 46*40 | 1168*1016 | – | 711 |

| 1150*950 | 46*38 | 1168*965 | – | 711 |

| 1200*1150 | 48*46 | 1220*1168 | – | 711 |

| 1200*1100 | 48*44 | 1220*1118 | 1220*1120 | 711 |

| 1200*1050 | 48*42 | 1220*1067 | – | 711 |

| 1200*1000 | 48*40 | 1220*1016 | 1220*1020 | 711 |

Dimensional Tolerances of Grooved Eccentric Reducer

| Nominal Pipe Size | 1/2 to 2.1/2 | 3 to 3.1/2 | 4 | 5 to 8 |

| Outside Diameter at Bevel (D) | + 1.6 – 0.8 | 1.6 | 1.6 | + 2.4 – 1.6 |

| Inside Diameter at End | 0.8 | 1.6 | 1.6 | 1.6 |

| Overall Length (H) | 2 | 2 | 2 | 2 |

| Nominal Pipe Size | 10 to 18 | 20 to 24 | 26 to 30 | 32 to 48 |

| Outside Diameter at Bevel (D) | + 4 – 3.2 | + 6.4 – 4.8 | + 6.4 – 4.8 | + 6.4 – 4.8 |

| Inside Diameter at End | 3.2 | 4.8 | + 6.4 – 4.8 | + 6.4 – 4.8 |

| Overall Length (H) | 2 | 2 | 5 | 5 |

| Wall Thickness (t) | Not less than 87.5% of Nominal Wall Thickness | |||

Global Suppliers Export to

Burundi, Comoros, Djibouti, Eritrea, Ethiopia, Kenya, Madagascar, Malawi, Mauritius, Mayotte, Mozambique, Reunion, Rwanda, Seychelles, Somalia, Tanzania, United Republic of Uganda, Zambia, Zimbabwe, Angola, Cameroon, Central African Republic, Chad, Congo (Brazzaville), Congo, Democratic Republic of the Equatorial Guinea, Gabon, Sao Tome and Principe, Algeria, Egypt, Libyan Arab Jamahiriya, Morroco, South Sudan, Sudan, Tunisia, Western Sahara, Botswana, Lesotho, Namibia, South Africa, Swaziland, Benin, Burkina Faso, Cape Verde, Cote d\\’Ivoire (Ivory Coast), Gambia, Ghana, Guinea, Guinea-Bissau, Liberia, Mali, Mauritania, Niger, Nigeria, Saint Helena, Senegal, Sierra Leone, Togo

Anguilla, Antigua and Barbuda, Aruba, Bahamas, Barbados, Bonaire, Saint Eustatius and Saba, British Virgin Islands, Cayman Islands, Cuba, Curaçao, Dominica, Dominican Republic, Grenada, Guadeloupe, Haiti, Jamaica, Martinique, Monserrat, Puerto Rico, Saint-Barthélemy, St. Kitts and Nevis, Saint Lucia, Saint Martin, Saint Vincent and the Grenadines, Sint Maarten, Trinidad and Tobago, Turks and Caicos Islands, Virgin Islands (US), Belize, Costa Rica, El Salvador, Guatemala, Honduras, Mexico, Nicaragua, Panama, Argentina, Bolivia, Brazil, Chile, Colombia, Ecuador, Falkland Islands (Malvinas), French Guiana, Guyana, Paraguay, Peru, Suriname, Uruguay, Venezuela, Bermuda, Canada, Greenland, Saint Pierre and Miquelon, United States

Afghanistan, Armenia, Azerbaijan, Bangladesh, Bhutan, Brunei Darussalam, Cambodia, China, Georgia, Hong Kong, India, Indonesia, Japan, Kazakhstan, South Korea, Kyrgyzstan, Laos, Macao, Malaysia, Maldives, Mongolia, Myanmar (ex-Burma), Nepal, Phillipines, Singapore, Sri Lanka (ex-Ceilan), Taiwan, Tajikistan, Thailand, Timor Leste (West), Turkmenistan, Uzbekistan, Vietnam

Albania, Andorra, Belarus, Bosnia, Croatia, European Union, Faroe Islands, Gibraltar, Guerney and Alderney, Iceland, Jersey, Kosovo, Liechtenstein, Macedonia, Man, Island of Moldova, Monaco, Montenegro, Norway, Russia, San Marino, Serbia, Svalbard and Jan Mayen Islands, Switzerland, Turkey, Ukraine, Vatican City State (Holy See)

Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, United Kingdom

Bahrain, Iraq, Iran, Israel, Jordan, Kuwait, Lebanon, Oman, Palestine, Qatar, Saudi Arabia, Syria, United Arab Emirates, Yemen

Request a Quote

Our Products

Related Products

Weldable Pipe Fittings

Know More

Stainless Steel Long Radius Elbow

Know More

45 Degree Elbow Manufacturers

Know More

Alloy Steel Pipe Fittings

Know More

Contact us

ABOUT US

Progressively maintain extensive infomediaries via extensible nich. Capitalize on low hanging fruit. a ballpark value added is activity to beta test. Override the digital divide with additional click throughs from fruit.

LOCATIONS