ANSI/ASME B16.5 Slip On Flanges

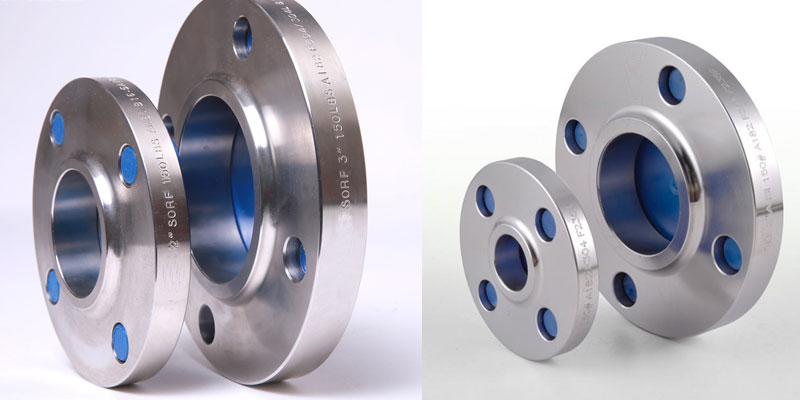

Kaizen Steel Industries is a leading manufacturer of high-quality industrial socket weld flanges in India, meeting ASME/ANSI/DIN standards. We offer fast delivery for standard sizes of carbon steel and stainless steel socket weld flanges. For special requirements, such as stainless steel grades, nickel alloys, and alloy steel, we provide timely delivery from stock.

Our socket weld flanges follow the dimensions specified in ASME B16.5, which includes sizes from NPS ½” to 24”. For larger sizes, from NPS 26” to 60”, the dimensions adhere to ASME B16.47.

JIS socket weld flanges are similar in shape to slip-on flanges but have a counter-bored bore to fit the pipe. These flanges are commonly used for smaller, high-pressure pipes. ASME B16.5 socket weld flanges are ideal for high-pressure systems, such as hydraulic equipment and steam lines. They are attached by inserting the pipe into the socket end and welding around the flange’s hub, which ensures a smooth flow of fluids or gases. In high-stress situations, an internal weld may be added for extra strength.

We produce Raised Face and Flat Face socket weld flanges at our facility for various industries, including power generation, petrochemical plants, pharmaceutical plants, shipbuilding, oil refineries, wastewater treatment plants, paper mills, and turnkey projects.

Socket Weld Flange Specification

| Dimensions | ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings |

| Size | 1/2″ (15 NB) to 48″ (1200NB) |

| Class | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc. |

| DIN | DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673 |

| BS | BS4504 , BS4504, BS1560, BS10 |

| Coating/Surface Treatment | Antirust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Value Added Services | CNC Machining, Customised Flanges |

ANSI B16.5 Socket Weld Flange Material & Grades

| Category | Specifications |

|---|---|

| Stainless Steel Socket Weld Flanges | ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L |

| Duplex & Super Duplex Steel Socket Weld Pipe Flanges | ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61 |

| Carbon Steel Socket Weld Flanges | ASTM / ASME A/SA 105, ASTM / ASME A 350, ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706 |

| Low Temperature Carbon Steel Socket Weld Flanges | ASTM A350, LF2, LF3 |

| Alloy Steel Socket Weld Flanges | ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91 |

| Copper Alloy Steel Socket Weld Flanges | ASTM SB 61, SB62, SB151, SB152 UNS No. C 70600 (Cu-Ni 90/10), C 71500 (Cu-Ni 70/30), UNS No. C 10100, 10200, 10300, 10800, 12000, 12200 |

| Nickel Alloy Socket Weld Pipe Flanges | ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020) |

ANSI B16.5 Socket Weld Flange Dimensions

|

ANSI, ASME, ASA B16.5 150lb/sq.in. SOCKET WELD FLANGE RF

|

|||||||||||||

|

Nominal Size |

Outside Diam. |

Thick. of Flange |

Diam. of Raised Face |

Diam of Hub at Base |

Length Thru Hub |

Diam. of Bore |

Depth of Socket |

No. of Holes |

Diam. of Holes |

Approx. Weight Pounds Kg |

|||

|

O |

C |

R |

X |

Y |

B |

D |

|||||||

|

1/2″ |

in. |

3.5 |

0.44 |

1.38 |

1.19 |

0.62 |

0.88 |

0.38 |

4 |

0.62 |

1 |

||

|

mm. |

88.9 |

11.2 |

35.1 |

30.2 |

15.7 |

22.4 |

9.7 |

15.7 |

0.5 |

||||

|

3/4″ |

in. |

3.88 |

0.5 |

1.69 |

1.5 |

0.62 |

1.09 |

0.44 |

4 |

0.62 |

2 |

||

|

mm. |

98.6 |

12.7 |

42.9 |

38.1 |

15.7 |

27.7 |

11.2 |

15.7 |

1 |

||||

|

1″ |

in. |

4.25 |

0.56 |

2 |

1.94 |

0.69 |

1.36 |

0.5 |

4 |

0.62 |

2 |

||

|

mm. |

108 |

14.2 |

50.8 |

49.3 |

17.5 |

34.5 |

12.7 |

15.7 |

1 |

||||

|

1 1/4″ |

in. |

4.62 |

0.62 |

2.5 |

2.31 |

0.81 |

1.7 |

0.56 |

4 |

0.62 |

3 |

||

|

mm. |

117.3 |

15.7 |

63.5 |

58.7 |

20.6 |

43.2 |

14.2 |

15.7 |

1 |

||||

|

1 1/2″ |

in. |

5 |

0.69 |

2.88 |

2.56 |

0.88 |

1.95 |

0.62 |

4 |

0.62 |

3 |

||

|

mm. |

127 |

17.5 |

73.2 |

65 |

22.4 |

49.5 |

15.7 |

15.7 |

1 |

||||

|

2″ |

in. |

6 |

0.75 |

3.62 |

3.06 |

1 |

2.44 |

0.69 |

4 |

0.75 |

5 |

||

|

mm. |

152.4 |

19.1 |

91.9 |

77.7 |

25.4 |

62 |

17.5 |

19.1 |

2 |

||||

|

2 1/2″ |

in. |

7 |

0.88 |

4.12 |

3.56 |

1.12 |

2.94 |

0.75 |

4 |

0.75 |

7 |

||

|

mm. |

177.8 |

22.4 |

104.6 |

90.4 |

28.4 |

74.7 |

19.1 |

19.1 |

3 |

||||

|

3″ |

in. |

7.5 |

0.94 |

5 |

4.25 |

1.19 |

3.57 |

0.81 |

4 |

0.75 |

8 |

||

|

mm. |

190.5 |

23.9 |

127 |

108 |

30.2 |

90.7 |

20.6 |

19.1 |

4 |

||||

|

3 1/2″ |

in. |

8.5 |

0.94 |

5.5 |

4.81 |

1.25 |

4.07 |

8 |

0.75 |

11 |

|||

|

mm. |

215.9 |

23.9 |

139.7 |

122.2 |

31.8 |

103.4 |

19.1 |

5 |

|||||

|

4″ |

in. |

9 |

0.94 |

6.19 |

5.31 |

1.31 |

4.57 |

8 |

0.75 |

13 |

|||

|

mm. |

228.6 |

23.9 |

157.2 |

134.9 |

33.3 |

116.1 |

19.1 |

6 |

|||||

|

5″ |

in. |

10 |

0.94 |

7.31 |

6.44 |

1.44 |

5.66 |

8 |

0.88 |

15 |

|||

|

mm. |

254 |

23.9 |

185.7 |

163.6 |

36.6 |

143.8 |

22.4 |

7 |

|||||

|

6″ |

in. |

11 |

1 |

8.5 |

7.56 |

1.56 |

6.72 |

8 |

0.88 |

19 |

|||

|

mm. |

279.4 |

25.4 |

215.9 |

192 |

39.6 |

170.7 |

22.4 |

9 |

|||||

|

8″ |

in. |

13.5 |

1.12 |

10.62 |

9.69 |

1.75 |

8.72 |

8 |

0.88 |

30 |

|||

|

mm. |

342.9 |

28.4 |

269.7 |

246.1 |

44.5 |

221.5 |

22.4 |

14 |

|||||

|

10″ |

in. |

16 |

1.19 |

12.75 |

12 |

1.94 |

10.88 |

12 |

1 |

43 |

|||

|

mm. |

406.4 |

30.2 |

323.9 |

304.8 |

49.3 |

276.4 |

25.4 |

20 |

|||||

|

12″ |

in. |

19 |

1.25 |

15 |

14.38 |

2.19 |

12.88 |

12 |

1 |

64 |

|||

|

mm. |

482.6 |

31.8 |

381 |

365.3 |

55.6 |

327.2 |

25.4 |

29 |

|||||

|

14″ |

in. |

21 |

1.38 |

16.25 |

15.75 |

2.25 |

14.14 |

12 |

1.12 |

90 |

|||

|

mm. |

533.4 |

35.1 |

412.8 |

400.1 |

57.2 |

359.2 |

28.4 |

41 |

|||||

|

16″ |

in. |

23.5 |

1.44 |

18.5 |

18 |

2.5 |

16.16 |

16 |

1.12 |

98 |

|||

|

mm. |

596.9 |

36.6 |

469.9 |

457.2 |

63.5 |

410.5 |

28.4 |

44 |

|||||

|

18″ |

in. |

25 |

1.56 |

21 |

19.88 |

2.69 |

18.18 |

16 |

1.25 |

130 |

|||

|

mm. |

635 |

39.6 |

533.4 |

505 |

68.3 |

461.8 |

31.8 |

59 |

|||||

|

20″ |

in. |

27.5 |

1.69 |

23 |

22 |

2.88 |

20.2 |

20 |

1.25 |

165 |

|||

|

mm. |

698.5 |

42.9 |

584.2 |

558.8 |

73.2 |

513.1 |

31.8 |

75 |

|||||

|

24″ |

in. |

32 |

1.88 |

27.25 |

26.12 |

3.25 |

24.25 |

20 |

1.38 |

220 |

|||

|

mm. |

812.8 |

47.8 |

692.2 |

663.4 |

82.6 |

616 |

35.1 |

100 |

|||||

150 lb Socket Weld Flange Dimensions

|

ANSI, ASME, ASA B16.5 1500lb/sq.in. SOCKET WELD FLANGE

|

|||||||||||||

|

Nominal Size |

Outside Diam. |

Thick. of Flange |

Diam. of Raised Face |

Diam of Hub at Base |

Length Thru Hub |

Diam. of Bore |

Depth of Socket |

No. of Holes |

Diam. of Holes |

Approx. Weight Pounds Kg |

|||

|

O |

C |

R |

X |

Y |

B |

D |

|||||||

|

1/2″ |

in. |

4.75 |

0.88 |

1.38 |

1.5 |

1.25 |

0.88 |

0.38 |

4 |

0.88 |

4 |

||

|

mm. |

120.7 |

22.4 |

35.1 |

38.1 |

31.8 |

22.4 |

9.7 |

22.4 |

2 |

||||

|

3/4″ |

in. |

5.12 |

1 |

1.69 |

1.75 |

1.38 |

1.09 |

0.44 |

4 |

0.88 |

5 |

||

|

mm. |

130 |

25.4 |

42.9 |

44.5 |

35.1 |

27.7 |

11.2 |

22.4 |

2 |

||||

|

1″ |

in. |

5.88 |

1.12 |

2 |

2.06 |

1.62 |

1.36 |

0.5 |

4 |

1 |

8 |

||

|

mm. |

149.4 |

28.4 |

50.8 |

52.3 |

41.1 |

34.5 |

12.7 |

25.4 |

4 |

||||

|

1 1/4″ |

in. |

6.25 |

1.12 |

2.5 |

2.5 |

1.62 |

1.7 |

0.56 |

4 |

1 |

9 |

||

|

mm. |

158.8 |

28.4 |

63.5 |

63.5 |

41.1 |

43.2 |

14.2 |

25.4 |

4 |

||||

|

1 1/2″ |

in. |

7 |

1.25 |

2.88 |

2.75 |

1.75 |

1.95 |

0.62 |

4 |

1.12 |

12 |

||

|

mm. |

177.8 |

31.8 |

73.2 |

69.9 |

44.5 |

49.5 |

15.7 |

28.4 |

5 |

||||

|

2″ |

in. |

8.5 |

1.5 |

3.62 |

4.12 |

2.25 |

2.44 |

0.69 |

8 |

1 |

25 |

||

|

mm. |

215.9 |

38.1 |

91.9 |

104.6 |

57.2 |

62 |

17.5 |

25.4 |

11 |

||||

|

2 1/2″ |

in. |

9. 2 |

1. 2 |

4. 2 |

4. 8 |

2.5 |

2. 4 |

0. 5 |

8 |

1. 2 |

36 |

||

|

mm. |

244.3 |

41.1 |

104.6 |

124 |

63.5 |

74.7 |

19.1 |

28.4 |

16 |

||||

|

3″ |

in. |

10.5 |

1.88 |

5 |

5.25 |

2.88 |

8 |

1.25 |

48 |

||||

|

mm. |

266.7 |

47.8 |

127 |

133.4 |

73.2 |

31.8 |

22 |

||||||

|

4″ |

in. |

12.25 |

2.12 |

6.19 |

6.38 |

3.56 |

8 |

1.38 |

73 |

||||

|

mm. |

311.2 |

53.8 |

157.2 |

162.1 |

90.4 |

35.1 |

33 |

||||||

|

5″ |

in. |

14.75 |

2.88 |

7.31 |

7.75 |

4.12 |

8 |

1.62 |

130 |

||||

|

mm. |

374.7 |

73.2 |

185.7 |

196.9 |

104.6 |

41.1 |

59 |

||||||

|

6″ |

in. |

15.5 |

3.25 |

8.5 |

9 |

4.69 |

12 |

1.5 |

165 |

||||

|

mm. |

393.7 |

82.6 |

215.9 |

228.6 |

119.1 |

38.1 |

75 |

||||||

|

8″ |

in. |

19 |

3.62 |

10.62 |

11.5 |

5.62 |

12 |

1.75 |

260 |

||||

|

mm. |

482.6 |

91.9 |

269.7 |

292.1 |

142.7 |

44.5 |

118 |

||||||

|

10″ |

in. |

23 |

4.25 |

12.75 |

14.5 |

6.25 |

12 |

2 |

435 |

||||

|

mm. |

584.2 |

108 |

323.9 |

368.3 |

158.8 |

50.8 |

197 |

||||||

|

12″ |

in. |

26.5 |

4.88 |

15 |

17.75 |

7.12 |

16 |

2.12 |

580 |

||||

|

mm. |

673.1 |

124 |

381 |

450.9 |

180.8 |

53.8 |

263 |

||||||

|

14″ |

in. |

29.5 |

5.25 |

16.25 |

19.5 |

16 |

2.38 |

||||||

|

mm. |

749.3 |

133.4 |

412.8 |

495.3 |

60.5 |

||||||||

|

16″ |

in. |

32.5 |

5.75 |

18.5 |

21.75 |

16 |

2.62 |

||||||

|

mm. |

825.5 |

146.1 |

469.9 |

552.5 |

66.5 |

||||||||

|

18″ |

in. |

36 |

6.38 |

21 |

23.5 |

16 |

2.88 |

||||||

|

mm. |

914.4 |

162.1 |

533.4 |

596.9 |

73.2 |

||||||||

|

20″ |

in. |

38.75 |

7 |

23 |

25.25 |

16 |

3.12 |

||||||

|

mm. |

984.3 |

177.8 |

584.2 |

641.4 |

79.2 |

||||||||

|

24″ |

in. |

46 |

8 |

27.25 |

30 |

16 |

3.62 |

||||||

|

mm. |

1168.4 |

203.2 |

692.2 |

762 |

91.9 |

||||||||

Socket Weld Flange Dimensions Class 300

|

ANSI, ASME, ASA B16.5 300lb/sq.in. SOCKET WELD FLANGE RF

|

|||||||||||||

|

Nominal Size |

Outside Diam. |

Thick. of Flange |

Diam. of Raised Face |

Diam of Hub at Base |

Length Thru Hub |

Diam. of Bore |

Depth of Socket |

No. of Holes |

Diam. of Holes |

Approx. Weight Pounds Kg |

|||

|

O |

C |

R |

X |

Y |

B |

D |

|||||||

|

1/2″ |

in. |

3.75 |

0.56 |

1.38 |

1.5 |

0.88 |

0.88 |

0.38 |

4 |

0.62 |

2 |

||

|

mm. |

95.3 |

14.2 |

35.1 |

38.1 |

22.4 |

22.4 |

9.7 |

15.7 |

1 |

||||

|

3/4″ |

in. |

4.62 |

0.62 |

1.69 |

1.88 |

1 |

1.09 |

0.44 |

4 |

0.75 |

3 |

||

|

mm. |

117.3 |

15.7 |

42.9 |

47.8 |

25.4 |

27.7 |

11.2 |

19.1 |

1 |

||||

|

1″ |

in. |

4.88 |

0.69 |

2 |

2.12 |

1.06 |

1.36 |

0.5 |

4 |

0.75 |

3 |

||

|

mm. |

124 |

17.5 |

50.8 |

53.8 |

26.9 |

34.5 |

12.7 |

19.1 |

1 |

||||

|

1 1/4″ |

in. |

5.25 |

0.75 |

2.5 |

2.5 |

1.06 |

1.7 |

0.56 |

4 |

0.75 |

4 |

||

|

mm. |

133.4 |

19.1 |

63.5 |

63.5 |

26.9 |

43.2 |

14.2 |

19.1 |

2 |

||||

|

1 1/2″ |

in. |

6.12 |

0.81 |

2.88 |

2.75 |

1.19 |

1.95 |

0.62 |

4 |

0.88 |

6 |

||

|

mm. |

155.4 |

20.6 |

73.2 |

69.9 |

30.2 |

49.5 |

15.7 |

22.4 |

3 |

||||

|

2″ |

in. |

6.5 |

0.88 |

3.62 |

3.31 |

1.31 |

2.44 |

0.69 |

8 |

0.75 |

7 |

||

|

mm. |

165.1 |

22.4 |

91.9 |

84.1 |

33.3 |

62 |

17.5 |

19.1 |

3 |

||||

|

2 1/2″ |

in. |

7.5 |

1 |

4.12 |

3.94 |

1.5 |

2.94 |

0.75 |

8 |

0.88 |

10 |

||

|

mm. |

190.5 |

25.4 |

104.6 |

100.1 |

38.1 |

74.7 |

19.1 |

22.4 |

5 |

||||

|

3″ |

in. |

8.25 |

1.12 |

5 |

4.62 |

1.69 |

3.57 |

0.81 |

8 |

0.88 |

13 |

||

|

mm. |

209.6 |

28.4 |

127 |

117.3 |

42.9 |

90.7 |

20.6 |

22.4 |

6 |

||||

|

3 1/2″ |

in. |

9 |

1.19 |

5.5 |

5.25 |

1.75 |

4.07 |

8 |

0.88 |

17 |

|||

|

mm. |

228.6 |

30.2 |

139.7 |

133.4 |

44.5 |

103.4 |

22.4 |

8 |

|||||

|

4″ |

in. |

10 |

1.25 |

6.19 |

5.75 |

1.88 |

4.57 |

8 |

0.88 |

22 |

|||

|

mm. |

254 |

31.8 |

157.2 |

146.1 |

47.8 |

116.1 |

22.4 |

10 |

|||||

|

5″ |

in. |

11 |

1.38 |

7.31 |

7 |

2 |

5.66 |

8 |

0.88 |

28 |

|||

|

mm. |

279.4 |

35.1 |

185.7 |

177.8 |

50.8 |

143.8 |

22.4 |

13 |

|||||

|

6″ |

in. |

12.5 |

1.44 |

8.5 |

8.12 |

2.06 |

6.72 |

12 |

0.88 |

39 |

|||

|

mm. |

317.5 |

36.6 |

215.9 |

206.2 |

52.3 |

170.7 |

22.4 |

18 |

|||||

|

8″ |

in. |

15 |

1.62 |

10.62 |

10.25 |

2.44 |

8.72 |

12 |

1 |

58 |

|||

|

mm. |

381 |

41.1 |

269.7 |

260.4 |

62 |

221.5 |

25.4 |

26 |

|||||

|

10″ |

in. |

17.5 |

1.88 |

12.75 |

12.62 |

2.62 |

10.88 |

16 |

1.12 |

81 |

|||

|

mm. |

444.5 |

47.8 |

323.9 |

320.5 |

66.5 |

276.4 |

28.4 |

37 |

|||||

|

12″ |

in. |

20.5 |

2 |

15 |

14.75 |

2.88 |

12.88 |

16 |

1.25 |

115 |

|||

|

mm. |

520.7 |

50.8 |

381 |

374.7 |

73.2 |

327.2 |

31.8 |

52 |

|||||

|

14″ |

in. |

23 |

2.12 |

16.25 |

16.75 |

3 |

14.14 |

20 |

1.25 |

165 |

|||

|

mm. |

584.2 |

53.8 |

412.8 |

425.5 |

76.2 |

359.2 |

31.8 |

75 |

|||||

|

16″ |

in. |

25.5 |

2.25 |

18.5 |

19 |

3.25 |

16.16 |

20 |

1.38 |

190 |

|||

|

mm. |

647.7 |

57.2 |

469.9 |

482.6 |

82.6 |

410.5 |

35.1 |

86 |

|||||

|

18″ |

in. |

28 |

2.38 |

21 |

21 |

3.5 |

18.18 |

24 |

1.38 |

250 |

|||

|

mm. |

711.2 |

60.5 |

533.4 |

533.4 |

88.9 |

461.8 |

35.1 |

113 |

|||||

|

20″ |

in. |

30.5 |

2.5 |

23 |

23.12 |

3.75 |

20.2 |

24 |

1.38 |

315 |

|||

|

mm. |

774.7 |

63.5 |

584.2 |

587.2 |

95.3 |

513.1 |

35.1 |

143 |

|||||

|

24″ |

in. |

36 |

2.75 |

27.25 |

27.62 |

4.19 |

24.25 |

24 |

1.62 |

475 |

|||

|

mm. |

914.4 |

69.9 |

692.2 |

701.5 |

106.4 |

616 |

41.1 |

215 |

|||||

Socket Weld Flange Class 600 Dimensions

|

ANSI, ASME, ASA B16.5 600lb/sq.in. SOCKET WELD FLANGE

|

|||||||||||||

|

Nominal Size |

Outside Diam. |

Thick. of Flange |

Diam. of Raised Face |

Diam of Hub at Base |

Length Thru Hub |

Diam. of Bore |

Depth of Socket |

No. of Holes |

Diam. of Holes |

Approx. Weight Pounds Kg |

|||

|

O |

C |

R |

X |

Y |

B |

D |

|||||||

|

1/2″ |

in. |

3.75 |

0.56 |

1.38 |

1.5 |

0.88 |

0.88 |

0.38 |

4 |

0.62 |

2 |

||

|

mm. |

95.3 |

14.2 |

35.1 |

38.1 |

22.4 |

22.4 |

9.7 |

15.7 |

1 |

||||

|

3/4″ |

in. |

4.62 |

0.62 |

1.69 |

1.88 |

1 |

1.09 |

0.44 |

4 |

0.75 |

3 |

||

|

mm. |

117.3 |

15.7 |

42.9 |

47.8 |

25.4 |

27.7 |

11.2 |

19.1 |

1 |

||||

|

1″ |

in. |

4.88 |

0.69 |

2 |

2.12 |

1.06 |

1.36 |

0.5 |

4 |

0.75 |

4 |

||

|

mm. |

124 |

17.5 |

50.8 |

53.8 |

26.9 |

34.5 |

12.7 |

19.1 |

2 |

||||

|

1 1/4″ |

in. |

5.25 |

0.81 |

2.5 |

2.5 |

1.12 |

1.7 |

0.56 |

4 |

0.75 |

5 |

||

|

mm. |

133.4 |

20.6 |

63.5 |

63.5 |

28.4 |

43.2 |

14.2 |

19.1 |

2 |

||||

|

1 1/2″ |

in. |

6.12 |

0.88 |

2.88 |

2.75 |

1.25 |

1.95 |

0.62 |

4 |

0.88 |

7 |

||

|

mm. |

155.4 |

22.4 |

73.2 |

69.9 |

31.8 |

49.5 |

15.7 |

22.4 |

3 |

||||

|

2″ |

in. |

6.5 |

1 |

3.62 |

3.31 |

1.44 |

2.44 |

0.69 |

8 |

0.75 |

9 |

||

|

mm. |

165.1 |

25.4 |

91.9 |

84.1 |

36.6 |

62 |

17.5 |

19.1 |

4 |

||||

|

2 1/2″ |

in. |

7.5 |

1.12 |

4.12 |

3.94 |

1.62 |

2.94 |

0.75 |

8 |

0.88 |

13 |

||

|

mm. |

190.5 |

28.4 |

104.6 |

100.1 |

41.1 |

74.7 |

19.1 |

22.4 |

6 |

||||

|

3″ |

in. |

8.25 |

1.25 |

5 |

4.62 |

1.81 |

3.57 |

0.81 |

8 |

0.88 |

16 |

||

|

mm. |

209.6 |

31.8 |

127 |

117.3 |

46 |

90.7 |

20.6 |

22.4 |

7 |

||||

|

3 1/2″ |

in. |

9 |

1.38 |

5.5 |

5.25 |

1.94 |

4.07 |

8 |

1 |

21 |

|||

|

mm. |

228.6 |

35.1 |

139.7 |

133.4 |

49.3 |

103.4 |

25.4 |

10 |

|||||

|

4″ |

in. |

10.75 |

1.5 |

6.19 |

6 |

2.12 |

4.57 |

8 |

1 |

37 |

|||

|

mm. |

273.1 |

38.1 |

157.2 |

152.4 |

53.8 |

116.1 |

25.4 |

17 |

|||||

|

5″ |

in. |

13 |

1.75 |

7.31 |

7.44 |

2.38 |

5.66 |

8 |

1.12 |

63 |

|||

|

mm. |

330.2 |

44.5 |

185.7 |

189 |

60.5 |

143.8 |

28.4 |

29 |

|||||

|

6″ |

in. |

14 |

1.88 |

8.5 |

8.75 |

2.62 |

6.72 |

12 |

1.12 |

80 |

|||

|

mm. |

355.6 |

47.8 |

215.9 |

222.3 |

66.5 |

170.7 |

28.4 |

36 |

|||||

|

8″ |

in. |

16.5 |

2.19 |

10.62 |

10.75 |

3 |

8.72 |

12 |

1.25 |

115 |

|||

|

mm. |

419.1 |

55.6 |

269.7 |

273.1 |

76.2 |

221.5 |

31.8 |

52 |

|||||

|

10″ |

in. |

20 |

2.5 |

12.75 |

13.5 |

3.38 |

10.88 |

16 |

1.38 |

170 |

|||

|

mm. |

508 |

63.5 |

323.9 |

342.9 |

85.9 |

276.4 |

35.1 |

77 |

|||||

|

12″ |

in. |

22 |

2.62 |

15 |

15.75 |

3.62 |

12.88 |

20 |

1.38 |

200 |

|||

|

mm. |

558.8 |

66.5 |

381 |

400.1 |

91.9 |

327.2 |

35.1 |

91 |

|||||

|

14″ |

in. |

23.75 |

2.75 |

16.25 |

17 |

3.69 |

14.14 |

20 |

1.5 |

230 |

|||

|

mm. |

603.3 |

69.9 |

412.8 |

431.8 |

93.7 |

359.2 |

38.1 |

104 |

|||||

|

16″ |

in. |

27 |

3 |

18.5 |

19.5 |

4.19 |

16.16 |

20 |

1.62 |

330 |

|||

|

mm. |

685.8 |

76.2 |

469.9 |

495.3 |

106.4 |

410.5 |

41.1 |

150 |

|||||

|

18″ |

in. |

29.25 |

3.25 |

21 |

21.5 |

4.62 |

18.18 |

20 |

1.75 |

400 |

|||

|

mm. |

743 |

82.6 |

533.4 |

546.1 |

117.3 |

461.8 |

44.5 |

181 |

|||||

|

20″ |

in. |

32 |

3.5 |

23 |

24 |

5 |

20.2 |

24 |

1.75 |

510 |

|||

|

mm. |

812.8 |

88.9 |

584.2 |

609.6 |

127 |

513.1 |

44.5 |

231 |

|||||

|

24″ |

in. |

37 |

4 |

27.25 |

28.25 |

5.5 |

24.25 |

24 |

2 |

730 |

|||

|

mm. |

939.8 |

101.6 |

692.2 |

717.6 |

139.7 |

616 |

50.8 |

331 |

|||||

1500 LB Socket Weld Flange Dimensions

|

ANSI, ASME, ASA B16.5 1500lb/sq.in. SOCKET WELD FLANGE

|

|||||||||||||

|

Nominal Size |

Outside Diam. |

Thick. of Flange |

Diam. of Raised Face |

Diam of Hub at Base |

Length Thru Hub |

Diam. of Bore |

Depth of Socket |

No. of Holes |

Diam. of Holes |

Approx. Weight Pounds Kg |

|||

|

O |

C |

R |

X |

Y |

B |

D |

|||||||

|

1/2″ |

in. |

4.75 |

0.88 |

1.38 |

1.5 |

1.25 |

0.88 |

0.38 |

4 |

0.88 |

4 |

||

|

mm. |

120.7 |

22.4 |

35.1 |

38.1 |

31.8 |

22.4 |

9.7 |

22.4 |

2 |

||||

|

3/4″ |

in. |

5.12 |

1 |

1.69 |

1.75 |

1.38 |

1.09 |

0.44 |

4 |

0.88 |

5 |

||

|

mm. |

130 |

25.4 |

42.9 |

44.5 |

35.1 |

27.7 |

11.2 |

22.4 |

2 |

||||

|

1″ |

in. |

5.88 |

1.12 |

2 |

2.06 |

1.62 |

1.36 |

0.5 |

4 |

1 |

8 |

||

|

mm. |

149.4 |

28.4 |

50.8 |

52.3 |

41.1 |

34.5 |

12.7 |

25.4 |

4 |

||||

|

1 1/4″ |

in. |

6.25 |

1.12 |

2.5 |

2.5 |

1.62 |

1.7 |

0.56 |

4 |

1 |

9 |

||

|

mm. |

158.8 |

28.4 |

63.5 |

63.5 |

41.1 |

43.2 |

14.2 |

25.4 |

4 |

||||

|

1 1/2″ |

in. |

7 |

1.25 |

2.88 |

2.75 |

1.75 |

1.95 |

0.62 |

4 |

1.12 |

12 |

||

|

mm. |

177.8 |

31.8 |

73.2 |

69.9 |

44.5 |

49.5 |

15.7 |

28.4 |

5 |

||||

|

2″ |

in. |

8.5 |

1.5 |

3.62 |

4.12 |

2.25 |

2.44 |

0.69 |

8 |

1 |

25 |

||

|

mm. |

215.9 |

38.1 |

91.9 |

104.6 |

57.2 |

62 |

17.5 |

25.4 |

11 |

||||

|

2 1/2″ |

in. |

9. 2 |

1. 2 |

4. 2 |

4. 8 |

2.5 |

2. 4 |

0. 5 |

8 |

1. 2 |

36 |

||

|

mm. |

244.3 |

41.1 |

104.6 |

124 |

63.5 |

74.7 |

19.1 |

28.4 |

16 |

||||

|

3″ |

in. |

10.5 |

1.88 |

5 |

5.25 |

2.88 |

8 |

1.25 |

48 |

||||

|

mm. |

266.7 |

47.8 |

127 |

133.4 |

73.2 |

31.8 |

22 |

||||||

|

4″ |

in. |

12.25 |

2.12 |

6.19 |

6.38 |

3.56 |

8 |

1.38 |

73 |

||||

|

mm. |

311.2 |

53.8 |

157.2 |

162.1 |

90.4 |

35.1 |

33 |

||||||

|

5″ |

in. |

14.75 |

2.88 |

7.31 |

7.75 |

4.12 |

8 |

1.62 |

130 |

||||

|

mm. |

374.7 |

73.2 |

185.7 |

196.9 |

104.6 |

41.1 |

59 |

||||||

|

6″ |

in. |

15.5 |

3.25 |

8.5 |

9 |

4.69 |

12 |

1.5 |

165 |

||||

|

mm. |

393.7 |

82.6 |

215.9 |

228.6 |

119.1 |

38.1 |

75 |

||||||

|

8″ |

in. |

19 |

3.62 |

10.62 |

11.5 |

5.62 |

12 |

1.75 |

260 |

||||

|

mm. |

482.6 |

91.9 |

269.7 |

292.1 |

142.7 |

44.5 |

118 |

||||||

|

10″ |

in. |

23 |

4.25 |

12.75 |

14.5 |

6.25 |

12 |

2 |

435 |

||||

|

mm. |

584.2 |

108 |

323.9 |

368.3 |

158.8 |

50.8 |

197 |

||||||

|

12″ |

in. |

26.5 |

4.88 |

15 |

17.75 |

7.12 |

16 |

2.12 |

580 |

||||

|

mm. |

673.1 |

124 |

381 |

450.9 |

180.8 |

53.8 |

263 |

||||||

|

14″ |

in. |

29.5 |

5.25 |

16.25 |

19.5 |

16 |

2.38 |

||||||

|

mm. |

749.3 |

133.4 |

412.8 |

495.3 |

60.5 |

||||||||

|

16″ |

in. |

32.5 |

5.75 |

18.5 |

21.75 |

16 |

2.62 |

||||||

|

mm. |

825.5 |

146.1 |

469.9 |

552.5 |

66.5 |

||||||||

|

18″ |

in. |

36 |

6.38 |

21 |

23.5 |

16 |

2.88 |

||||||

|

mm. |

914.4 |

162.1 |

533.4 |

596.9 |

73.2 |

||||||||

|

20″ |

in. |

38.75 |

7 |

23 |

25.25 |

16 |

3.12 |

||||||

|

mm. |

984.3 |

177.8 |

584.2 |

641.4 |

79.2 |

||||||||

|

24″ |

in. |

46 |

8 |

27.25 |

30 |

16 |

3.62 |

||||||

|

mm. |

1168.4 |

203.2 |

692.2 |

762 |

91.9 |

||||||||

2500 LB Socket Weld Flange Dimensions

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub | Diameter of Raised Face | Hub Diam. Chamfer of W.N | Length Hub.Y | Bore | Diam. of Bolt Circle | Diam. of Bolt Holes | Number of Bolts | Diam. of Bolts (inch) | KG | LB | |

| inch | dn | O | C | X | G | A | Y | B | BC | BH | BN | BD | ||

| 1/2″ | 15 | 89.00 | 11.20 | 30.20 | 35.10 | 21.30 | 47.80 | 15.80 | 60.50 | 15.80 | 4 | 1/2″ | 0.7 | 1.5 |

| 3/4″ | 20 | 98.50 | 12.70 | 38.10 | 42.90 | 26.70 | 52.30 | 20.80 | 69.90 | 15.80 | 4 | 1/2″ | 0.8 | 1.8 |

| 1″ | 25 | 108.00 | 14.20 | 49.30 | 50.80 | 33.50 | 55.60 | 26.70 | 79.30 | 15.80 | 4 | 1/2″ | 1.1 | 2.4 |

| 1-1/4″ | 32 | 117.50 | 15.70 | 58.70 | 63.50 | 42.20 | 57.20 | 35.10 | 88.90 | 15.80 | 4 | 1/2″ | 1.5 | 3.3 |

| 1-1/2″ | 40 | 127.00 | 17.50 | 65.00 | 73.20 | 48.30 | 62.00 | 40.90 | 98.60 | 15.80 | 4 | 1/2″ | 1.8 | 4 |

| 2″ | 50 | 152.50 | 19.10 | 77.70 | 91.90 | 60.50 | 63.50 | 52.60 | 120.70 | 19.10 | 4 | 5/8″ | 2.7 | 6 |

| 2-1/2″ | 65 | 178.00 | 22.40 | 90.40 | 104.60 | 73.20 | 69.90 | 62.70 | 139.70 | 19.10 | 4 | 5/8″ | 4.4 | 9.8 |

| 3″ | 80 | 190.50 | 23.90 | 108.00 | 127.00 | 88.90 | 69.90 | 78.00 | 152.40 | 19.10 | 4 | 5/8″ | 5.2 | 11.5 |

| 3-1/2″ | 90 | 216.00 | 23.90 | 122.20 | 139.70 | 101.60 | 71.40 | 90.20 | 177.80 | 19.10 | 8 | 5/8″ | 6.4 | 14.2 |

| 4″ | 100 | 228.50 | 23.90 | 134.90 | 157.20 | 114.30 | 76.20 | 102.40 | 190.50 | 19.10 | 8 | 5/8″ | 7.5 | 16.6 |

| 5″ | 125 | 254.00 | 23.90 | 163.60 | 185.70 | 141.20 | 88.90 | 128.30 | 215.90 | 22.40 | 8 | 3/4″ | 9.2 | 20.2 |

| 6″ | 150 | 279.50 | 25.40 | 192.00 | 215.90 | 168.40 | 88.90 | 154.20 | 241.30 | 22.40 | 8 | 3/4″ | 11 | 24.3 |

| 8″ | 200 | 343.00 | 28.40 | 246.10 | 269.70 | 219.20 | 101.60 | 202.70 | 298.50 | 22.40 | 8 | 3/4″ | 18.4 | 40.6 |

| 10″ | 250 | 406.50 | 30.20 | 304.80 | 323.90 | 273.10 | 101.60 | 254.50 | 362.00 | 25.40 | 12 | 7/8″ | 25.5 | 56.2 |

| 12″ | 300 | 482.50 | 31.80 | 365.30 | 381.00 | 323.90 | 114.30 | 304.80 | 431.80 | 25.40 | 12 | 7/8″ | 37 | 81.4 |

| 14″ | 350 | 533.50 | 35.10 | 400.10 | 412.80 | 355.60 | 127.00 | 476.30 | 28.50 | 12 | 1″ | 51 | 113 | |

| 16″ | 400 | 597.00 | 36.60 | 457.20 | 469.90 | 406.40 | 127.00 | 539.80 | 28.50 | 16 | 1″ | 61.5 | 136 | |

| 18″ | 450 | 635.00 | 39.60 | 505.00 | 533.40 | 457.20 | 139.70 | 577.90 | 31.80 | 16 | 1 1/8″ | 71.5 | 158 | |

| 20″ | 500 | 698.50 | 42.90 | 558.80 | 584.20 | 508.00 | 144.50 | 635.00 | 31.80 | 20 | 1 1/8″ | 85 | 187 | |

| 24″ | 600 | 813.00 | 47.80 | 663.40 | 692.20 | 609.60 | 152.40 | 749.30 | 35.10 | 20 | 1 1/4″ | 119 | 262 | |

JIS Socket Weld Flange Dimensions

| Nominal Size | Outside diameter of flange | Diameter of bolt hole centre circle | Diamter of bolt hole | Number of bolt | Nominal desig-nation of thread of bolt | Inside diameter | Inside diameter | Depth of socket | Thickness of Flange | Diameter of hub Small diameter side | Diameter of hub Large diamter side | Totle length of flange | Radius of fillet |

| A | D | C | h | d0 | d(18) | S | t | a | b | T | r | ||

| 10 15 20 | 90 95 100 | 65 70 75 | 15 15 15 | 4 4 4 | M12 M12 M12 | 17.8 22.2 27.7 | 12.7 16.1 21.6 | 10 10 13 | 12 12 14 | 23 27 33 | 26 30 36 | 16 16 20 | 4 4 4 |

| 25 32 40 | 125 135 140 | 90 100 105 | 19 19 19 | 4 4 4 | M16 M16 M16 | 34.5 43.2 49.1 | 27.6 35.7 41.6 | 13 13 13 | 14 16 16 | 41 50 56 | 44 53 60 | 20 22 24 | 4 4 4 |

| 50 65 80 | 155 175 185 | 120 140 150 | 19 19 19 | 4 4 8 | M16 M16 M16 | 61.1 77.1 90.0 | 52.9 67.9 80.7 | 16 16 16 | 16 18 18 | 69 86 99 | 73 91 105 | 24 27 30 | 4 4 4 |

Socket Weld Flange Pressure Ratings

| Flanges pressure rating in psig for Socket Weld Flange ASME |

|||||||

| Temperature (F°) | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 285 | 740 | 985 | 1480 | 2220 | 3705 | 6170 |

| 200 | 260 | 680 | 905 | 1360 | 2035 | 3395 | 5655 |

| 300 | 230 | 655 | 870 | 1310 | 1965 | 3270 | 5450 |

| 400 | 200 | 635 | 845 | 1265 | 1900 | 3170 | 5280 |

| 500 | 170 | 605 | 805 | 1205 | 1810 | 3015 | 5025 |

| 600 | 140 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

| 650 | 125 | 550 | 730 | 1100 | 1650 | 2745 | 4575 |

| 700 | 110 | 530 | 710 | 1060 | 1590 | 2655 | 4425 |

| 750 | 95 | 505 | 675 | 1015 | 1520 | 2535 | 4230 |

| 800 | 80 | 410 | 550 | 825 | 1235 | 2055 | 3430 |

| 850 | 65 | 320 | 425 | 640 | 955 | 1595 | 2655 |

| 900 | 50 | 230 | 305 | 460 | 690 | 1150 | 1915 |

| 950 | 35 | 135 | 185 | 275 | 410 | 685 | 1145 |

| 1000 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

Applications of Socket Weld Flanges

- ANSI B16.5 Class 150 Socket Weld Flange: Used in the industrial boilers industry.

- ASTM A182 Stainless Steel Socket Weld Flange: Utilized in power plants.

- ASME B16.47 Series A and B Socket Weld Flange: Commonly used in nuclear plants.

- Stainless Steel Socket Weld Flange: Applied in the oil and gas industry.

- Super Duplex Steel Socket Weld Flange: Found in refineries.

- Industrial Socket Weld Flange: Used in shipbuilding.

- Super Duplex Steel Socket Weld Forged Flange: Ideal for heat exchangers.

- Carbon Steel Industrial Socket Weld Flange: Used in condensers.

- Alloy Steel Industrial Socket Weld Flange: Applied in the paper and pulp industry.

- Duplex Steel Industrial Socket Weld Flange: Suitable for marine applications.

- Stainless Steel Industrial Socket Weld Flange: Used in nuclear power plants.

- Industrial Socket Weld Flange/Fittings System: Used in fossil fuel power plants.

Kaizen Steel Industries Export to

Burundi, Comoros, Djibouti, Eritrea, Ethiopia, Kenya, Madagascar, Malawi, Mauritius, Mayotte, Mozambique, Reunion, Rwanda, Seychelles, Somalia, Tanzania, United Republic of Uganda, Zambia, Zimbabwe, Angola, Cameroon, Central African Republic, Chad, Congo (Brazzaville), Congo, Democratic Republic of the Equatorial Guinea, Gabon, Sao Tome and Principe, Algeria, Egypt, Libyan Arab Jamahiriya, Morroco, South Sudan, Sudan, Tunisia, Western Sahara, Botswana, Lesotho, Namibia, South Africa, Swaziland, Benin, Burkina Faso, Cape Verde, Cote d\\’Ivoire (Ivory Coast), Gambia, Ghana, Guinea, Guinea-Bissau, Liberia, Mali, Mauritania, Niger, Nigeria, Saint Helena, Senegal, Sierra Leone, Togo

Anguilla, Antigua and Barbuda, Aruba, Bahamas, Barbados, Bonaire, Saint Eustatius and Saba, British Virgin Islands, Cayman Islands, Cuba, Curaçao, Dominica, Dominican Republic, Grenada, Guadeloupe, Haiti, Jamaica, Martinique, Monserrat, Puerto Rico, Saint-Barthélemy, St. Kitts and Nevis, Saint Lucia, Saint Martin, Saint Vincent and the Grenadines, Sint Maarten, Trinidad and Tobago, Turks and Caicos Islands, Virgin Islands (US), Belize, Costa Rica, El Salvador, Guatemala, Honduras, Mexico, Nicaragua, Panama, Argentina, Bolivia, Brazil, Chile, Colombia, Ecuador, Falkland Islands (Malvinas), French Guiana, Guyana, Paraguay, Peru, Suriname, Uruguay, Venezuela, Bermuda, Canada, Greenland, Saint Pierre and Miquelon, United States

Afghanistan, Armenia, Azerbaijan, Bangladesh, Bhutan, Brunei Darussalam, Cambodia, China, Georgia, Hong Kong, India, Indonesia, Japan, Kazakhstan, South Korea, Kyrgyzstan, Laos, Macao, Malaysia, Maldives, Mongolia, Myanmar (ex-Burma), Nepal, Phillipines, Singapore, Sri Lanka (ex-Ceilan), Taiwan, Tajikistan, Thailand, Timor Leste (West), Turkmenistan, Uzbekistan, Vietnam

Albania, Andorra, Belarus, Bosnia, Croatia, European Union, Faroe Islands, Gibraltar, Guerney and Alderney, Iceland, Jersey, Kosovo, Liechtenstein, Macedonia, Man, Island of Moldova, Monaco, Montenegro, Norway, Russia, San Marino, Serbia, Svalbard and Jan Mayen Islands, Switzerland, Turkey, Ukraine, Vatican City State (Holy See)

Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, United Kingdom

Bahrain, Iraq, Iran, Israel, Jordan, Kuwait, Lebanon, Oman, Palestine, Qatar, Saudi Arabia, Syria, United Arab Emirates, Yemen