ANSI / ASME B16.5 Tongue and Groove Flanges

Table of Content

- Tongue & Groove Flanges Specification

- Tongue and Groove Flange Material & Grades

- Type of ASME B16.5 Tongue & Groove Flanges

- ASME B16.5 Tongue And Groove Flanges Dimensions

- ANSI B16.5 Class 150 Tongue & Groove Flanges Dimensions

- ANSI B16.5 Class 300 Tongue & Groove Flanges Dimensions

- Applications of Tongue & Groove Flanges Boss

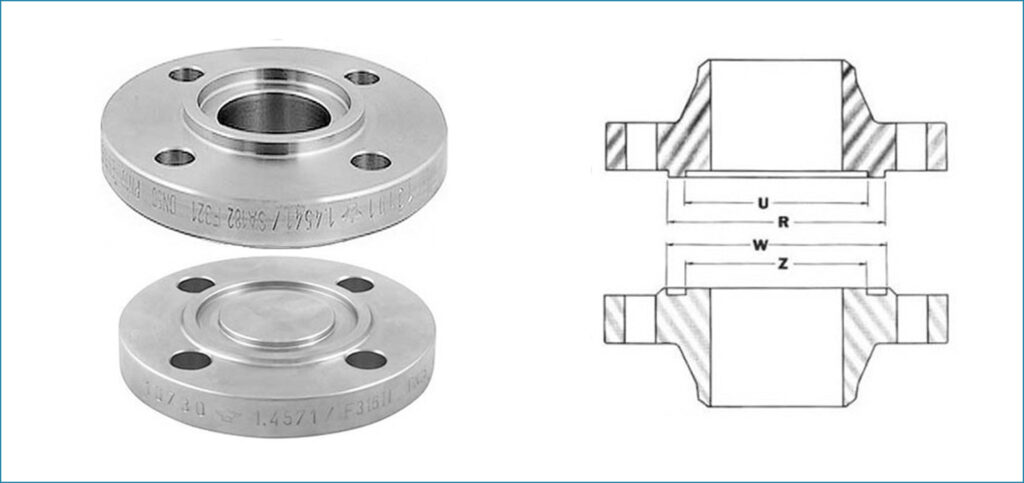

Kaizen Steel Industries is a manufacturer, supplier, and exporter of Tongue & Groove Flanges, known for their precision and quality. In Stainless Steel Tongue & Groove Flanges, the Tongue Flange has a raised ring on its surface, while the Groove Flange features a matching depression. For a watertight connection, it is essential to align these flange faces properly.

Alloy 20 Groove & Tongue Flanges align on their own, and they do not come into contact with the fluid or gas inside the pipe, preventing corrosion. Nickel Tongue & Groove Flanges are commonly used in the chemical, petroleum, and crude oil extraction industries.

The ANSI B16.5 standard for Tongue & Groove Flanges covers several key aspects, including pressure-temperature ratings, materials, tolerances, marking, and testing for pipe flanges in sizes ranging from NPS 26 to NPS 60. Additionally, the specification outlines the dimensions for Tongue & Groove Flanges. The ANSI B16.5 Class 150 Tongue & Groove Flanges also includes flanges with pressure ratings for classes 75, 150, 300, 400, 600, and 900. The requirements in the ASME B16.5 standard are provided in both Metric (SI) and U.S. Customary units, with bolt and bolt hole diameters expressed in inches.

The Hastelloy C22 Tongue & Groove Flange, also known as Groove & Tongue or Tongue, is similar in shape to a slip-on flange, but the bore is designed with a Groove & Tongue configuration. This allows the flange to be assembled without welding. The threads in the Tongue & Groove Flanges are tapered, creating a seal between the flange and the pipe as the tapers match in diameter.

The ASTM A182 SS Tongue & Groove Flange specification covers forged low alloy and stainless steel components used in pressure systems. This specification includes flanges like Tongue & Groove Flanges, fittings, valves, and other parts with specific dimensions or standards.

DIN86029 PN10 Tongue & Groove Flanges are designed for special conditions. A key benefit of using Copper Nickel Tongue & Groove Flanges is that they can be attached to the pipe without welding. Surface treatment for Carbon Steel large tongue and groove flanges can be done using various methods, such as applying anti-rust paint, yellow transparent coating, oil black paint, zinc plating, or hot and cold dip galvanizing.

The face types for Alloy 20 Tongue & Groove Flanges include Flat Face (FF), Raised Face (RF), and Ring Type Joint (RTJ). Class 300 Tongue & Groove Flanges are used in various industries, including water systems, shipbuilding, oil fields, offshore projects, natural gas, electric power, and pipe projects.

We are one of the largest manufacturers of tongue and groove flanges. We also supply, trade, and export Groove & Tongue Flanges. Click here to learn more about the price of Stainless Steel Tongue & Groove Flanges.

Tongue & Groove Flanges Specification

| Dimensions | ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings |

| Size | 1/2″ (15 NB) to 48″ (1200NB) |

| DIN | DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673 |

| BS | BS4504 , BS4504, BS1560, BS10 |

| Class | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Tongue and Groove Flange Material & Grades

| Stainless Steel Tongue and Groove Flange | ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L |

| Duplex & Super Duplex Steel Groove and Tongue Flange | ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61 |

| Carbon Steel Tongue and Groove Flange | ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706 |

| Low Temperature Carbon Steel Groove and Tongue Flange | ASTM A350, LF2, LF3 |

| Alloy Steel Groove and Tongue Flange | ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91 |

| Copper Alloy Steel Tongue and Groove Flange | ASTM SB 61 , SB62 , SB151 , SB152 UNS No. C 70600 (Cu-Ni 90/10), C 71500 (Cu-Ni 70/30), UNS No. C 10100, 10200, 10300, 10800, 12000, 12200 |

| Nickel Alloy Groove and Tongue Flange | ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020) |

Type of ASME B16.5 Tongue & Groove Flanges

ASME B16.5 Tongue and Groove Flanges

Class 6000 elbow, Threaded Union

ANSI B16.5 Tongue and Groove Type Flange

ASME B16.47 Series a Tongue and Groove Weld Neck Flange

ASME B16.47 Series b Tongue and Groove Face Flange

ANSI B16.5 Class 150 Tongue and Groove Blind Flange

ASME B16.5 Class 300 Tongue and Groove Flange Connection

Large Tongue and Groove Flange EN 1092-1 Type 02

EN 1092-2 PN16 Tongue and Groove In Flanges

Forged Tongue and Groove Face Flange

AWWA C207 Class d Small Tongue and Groove Flange

MSS SP-44 Tongue and Groove Flanges

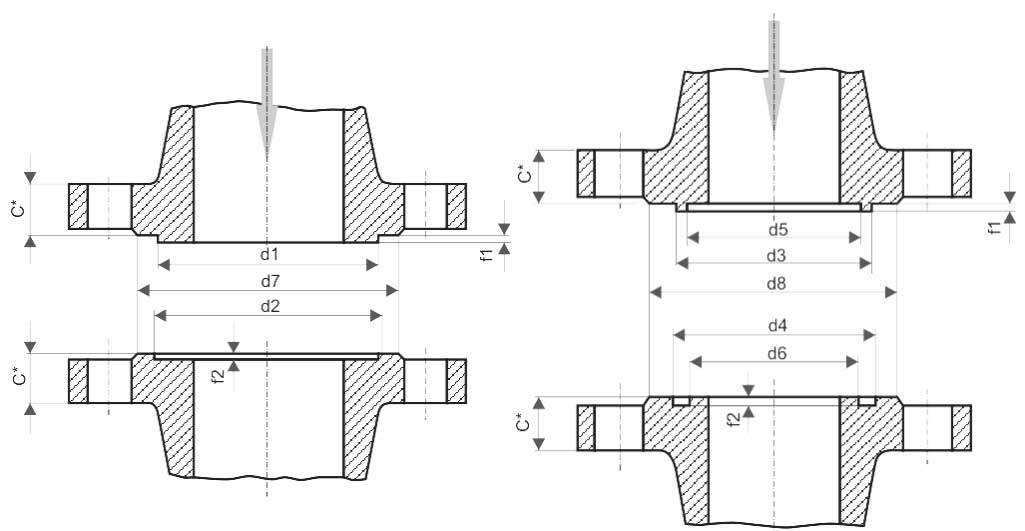

ASME B16.5 Tongue And Groove Flanges Dimensions

| DN | D1 | D2 | D3 | D4 | D5 | D6 | D7 | D8 | F1 | F2 |

|---|---|---|---|---|---|---|---|---|---|---|

| ½” | 1,38 (35,1) | 1,44 (36,6) | 1,38 (35,1) | 1,44 (36,6) | 1,00 (25,4) | 0,94 (23,9) | 1,81 (46,0) | 1,75 (44,5) | 0,25 (6,4) | 0,19 (4,8) |

| ¾” | 1,69 (42,9) | 1,75 (44,5) | 1,69 (42,9) | 1,75 (44,5) | 1,31 (33,3) | 1,25 (31,8) | 2,12 (53,8) | 2,06 (52,3) | 0,25 (6,4) | 0,19 (4,8) |

| 1″ | 2,00 (50,8) | 2,06 (52,3) | 1,88 (47,7) | 1,94 (49,3) | 1,50 (38,1) | 1,44 (36,6) | 2,44 (62,0) | 2,25 (57,2) | 0,25 (6,4) | 0,19 (4,8) |

| 1¼” | 2,50 (63,5) | 2,56 (65,0) | 2,25 (57,2) | 2,31 (58,7) | 1,88 (47,8) | 1,81 (46,0) | 2,94 (74,7) | 2,62 (66,6) | 0,25 (6,4) | 0,19 (4,8) |

| 1½” | 2,88 (73,2) | 2,94 (74,7) | 2,50 (63,5) | 2,56 (65,0) | 2,12 (53,8) | 2,06 (52,3) | 3,31 (84,1) | 2,88 (73,2) | 0,25 (6,4) | 0,19 (4,8) |

| 2″ | 3,62 (92,0) | 3,69 (93,7) | 3,25 (82,6) | 3,31 (84,1) | 2,88 (73,0) | 2,81 (71,4) | 4,06 (103,1) | 3,62 (92,0) | 0,25 (6,4) | 0,19 (4,8) |

| 2½” | 4,12 (104,6) | 4,19 (106,4) | 3,75 (95,2) | 3,81 (96,8) | 3,38 (85,8) | 3,31 (84,1) | 4,56 (115,8) | 4,12 (104,6) | 0,25 (6,4) | 0,19 (4,8) |

| 3″ | 5,00 (127,0) | 5,06 (128,5) | 4,62 (117,5) | 4,69 (119,1) | 4,25 (108,0) | 4,19 (106,4) | 5,44 (138,2) | 5,00 (127,0) | 0,25 (6,4) | 0,19 (4,8) |

| 4″ | 6,19 (157,2) | 6,25 (158,8) | 5,69 (144,5) | 5,75 (146,1) | 5,19 (131,8) | 5,12 (130,0) | 6,62 (168,1) | 6,19 (157,2) | 0,25 (6,4) | 0,19 (4,8) |

| 5″ | 7,31 (185,7) | 7,38 (187,5) | 6,81 (173,0) | 6,88 (174,8) | 6,31 (160,3) | 6,25 (158,8) | 7,75 (196,9) | 7,31 (185,7) | 0,25 (6,4) | 0,19 (4,8) |

| 6″ | 8,50 (215,9) | 8,56 (217,5) | 8,00 (203,2) | 8,06 (204,7) | 7,50 (190,5) | 7,44 (189,0) | 8,94 (227,0) | 8,50 (215,9) | 0,25 (6,4) | 0,19 (4,8) |

| 8″ | 10,62 (269,8) | 10,69 (271,5) | 10,00 (254,0) | 10,06 (255,5) | 9,38 (238,3) | 9,31 (236,5) | 11,06 (281,0) | 10,62 (269,8) | 0,25 (6,4) | 0,19 (4,8) |

| 10″ | 12,75 (323,5) | 12,81 (325,4) | 12,00 (304,8) | 12,06 (306,3) | 11,25 (285,8) | 11,19 (284,2) | 13,19 (335,0) | 12,75 (323,5) | 0,25 (6,4) | 0,19 (4,8) |

| 12″ | 15,00 (381,0) | 15,06 (382,5) | 14,25 (362,0) | 14,31 (363,5) | 13,50 (342,9) | 13,44 (341,4) | 15,44 (392,2) | 15,00 (381,0) | 0,25 (6,4) | 0,19 (4,8) |

| 14″ | 16,25 (412,8) | 16,31 (414,3) | 15,50 (393,7) | 15,56 (395,2) | 14,75 (374,7) | 14,69 (373,1) | 16,69 (423,9) | 16,25 (412,8) | 0,25 (6,4) | 0,19 (4,8) |

| 16″ | 18,50 (469,9) | 18,56 (471,5) | 17,62 (447,6) | 17,69 (449,3) | 16,75 (425,5) | 16,69 (423,9) | 18,94 (481,0) | 18,50 (469,9) | 0,25 (6,4) | 0,19 (4,8) |

| 18″ | 21,00 (533,4) | 21,06 (535,0) | 20,12 (511,0) | 20,19 (512,8) | 19,25 (489,0) | 19,19 (487,4) | 21,44 (544,6) | 21,00 (533,4) | 0,25 (6,4) | 0,19 (4,8) |

| 20″ | 23,00 (584,2) | 23,06 (585,8) | 22,00 (558,8) | 22,06 (560,3) | 21,00 (533,4) | 20,94 (531,9) | 23,44 (595,4) | 23,00 (584,2) | 0,25 (6,4) | 0,19 (4,8) |

| 24″ | 27,25 (692,2) | 27,31 (693,7) | 26,25 (666,8) | 26,31 (668,3) | 25,25 (641,4) | 25,19 (639,8) | 27,69 (703,3) | 27,25 (692,2) | 0,25 (6,4) | 0,19 (4,8) |

ANSI B16.5 Class 150 Tongue & Groove Flanges Dimensions

| Nominal | Large Tongue | Large Tongue | Gasket | Number | Size of | Bolt Torque | Comp Force | Max. Gasket | Internal | Min. Rec’d | Min. Rec’d | Max. Rec’d/Avail. | Preferred |

| Pipe Size | Contact I.D. | Contact O.D. | Contact Area | Of | Bolts | at 60ksi Stress | Per Bolt @ 60ksi | Stress Avail. | Pressure | Gasket Stress | Torque/Bolt | Gasket Stress | Torque/Bolt |

| (in) | (in) | (in) | (sq.in.) | Bolts | (in) | (ft.lbs.) | (psi) | (psi) | (psig) | (psi) | (ft.lbs.) | (psi) | (ft.lbs.) |

| 0.5 | 1.00 | 1.38 | 0.71 | 4 | 0.50 | 60 | 7560 | 42594 | <300 | 4800 | 7 | 10000 | 14 |

| 0.75 | 1.31 | 1.69 | 0.89 | 4 | 0.50 | 60 | 7560 | 33791 | <300 | 4800 | 9 | 10000 | 18 |

| 1 | 1.50 | 2.00 | 1.37 | 4 | 0.50 | 60 | 7560 | 22013 | <300 | 4800 | 13 | 10000 | 27 |

| 1.25 | 1.88 | 2.50 | 2.13 | 4 | 0.50 | 60 | 7560 | 14186 | <300 | 4800 | 20 | 10000 | 42 |

| 1.5 | 2.12 | 2.88 | 2.98 | 4 | 0.50 | 60 | 7560 | 10137 | <300 | 4800 | 28 | 10000 | 59 |

| 2 | 2.88 | 3.62 | 3.78 | 4 | 0.63 | 120 | 12120 | 12839 | <300 | 4800 | 45 | 10000 | 93 |

| 2.5 | 3.38 | 4.12 | 4.36 | 4 | 0.63 | 120 | 12120 | 11128 | <300 | 4800 | 52 | 10000 | 108 |

| 3 | 4.25 | 5.00 | 5.45 | 4 | 0.63 | 120 | 12120 | 8902 | <300 | 4800 | 65 | 8902 | 120 |

| 3.5 | 4.75 | 5.50 | 6.03 | 8 | 0.63 | 120 | 12120 | 16067 | <300 | 4800 | 36 | 10000 | 75 |

| 4 | 5.19 | 6.19 | 8.93 | 8 | 0.63 | 120 | 12120 | 10854 | <300 | 4800 | 53 | 10854 | 120 |

| 5 | 6.31 | 7.31 | 10.69 | 8 | 0.75 | 200 | 18120 | 13558 | <300 | 4800 | 71 | 13558 | 200 |

| 6 | 7.50 | 8.50 | 12.56 | 8 | 0.75 | 200 | 18120 | 11541 | <300 | 4800 | 83 | 11541 | 200 |

| 8 | 9.38 | 10.62 | 19.47 | 8 | 0.75 | 200 | 18120 | 7446 | <300 | 4800 | 129 | 7446 | 200 |

| 10 | 11.25 | 12.75 | 28.26 | 12 | 0.88 | 320 | 25140 | 10675 | <300 | 4800 | 144 | 10675 | 320 |

| 12 | 13.50 | 15.00 | 33.56 | 12 | 0.88 | 320 | 25140 | 8990 | <300 | 4800 | 171 | 8990 | 320 |

| 14 | 14.75 | 16.25 | 36.50 | 12 | 1.00 | 490 | 33060 | 10868 | <300 | 4800 | 216 | 10868 | 490 |

| 16 | 16.75 | 18.50 | 48.42 | 16 | 1.00 | 490 | 33060 | 10923 | <300 | 4800 | 215 | 10923 | 490 |

| 18 | 19.25 | 21.00 | 55.29 | 16 | 1.13 | 710 | 43680 | 12639 | <300 | 4800 | 270 | 12639 | 710 |

| 20 | 21.00 | 23.00 | 69.08 | 20 | 1.13 | 710 | 43680 | 12646 | <300 | 4800 | 269 | 12646 | 710 |

| 24 | 25.25 | 27.25 | 82.43 | 20 | 1.25 | 1000 | 55740 | 13525 | <300 | 4800 | 355 | 13525 | 1000 |

ANSI B16.5 Class 300 Tongue & Groove Flanges Dimensions

|

Nominal |

Large Tongue |

Large Tongue |

Gasket |

Number |

Size of |

Bolt Torque |

Comp Force |

Max. Gasket |

Internal |

Min. Rec’d |

Min. Rec’d |

Max. Rec’d/Avail. |

Preferred |

|

Pipe Size |

Contact I.D. |

Contact O.D. |

Contact Area |

Of |

Bolts |

at 60ksi Stress |

Per Bolt @ 60ksi |

Stress Avail. |

Pressure |

Gasket Stress |

Torque/Bolt |

Gasket Stress |

Torque/Bolt |

|

(in) |

(in) |

(in) |

(sq.in.) |

Bolts |

(in) |

(ft.lbs.) |

(psi) |

(psi) |

(psig) |

(psi) |

(ft.lbs.) |

(psi) |

(ft.lbs.) |

|

0.5 |

1.00 |

1.38 |

0.71 |

4 |

0.50 |

60 |

7560 |

42594 |

<800 |

6200 |

12 |

10000 |

14 |

|

0.75 |

1.31 |

1.69 |

0.89 |

4 |

0.63 |

120 |

12120 |

54174 |

<800 |

6200 |

21 |

10000 |

22 |

|

1 |

1.50 |

2.00 |

1.37 |

4 |

0.63 |

120 |

12120 |

35290 |

<800 |

6400 |

28 |

10000 |

34 |

|

1.25 |

1.88 |

2.50 |

2.13 |

4 |

0.63 |

120 |

12120 |

22742 |

<800 |

6400 |

43 |

10000 |

53 |

|

1.5 |

2.12 |

2.88 |

2.98 |

4 |

0.75 |

200 |

18120 |

24298 |

<800 |

6400 |

64 |

10000 |

82 |

|

2 |

2.88 |

3.62 |

3.78 |

8 |

0.63 |

120 |

12120 |

25679 |

<800 |

6400 |

46 |

10000 |

47 |

|

2.5 |

3.38 |

4.12 |

4.36 |

8 |

0.75 |

200 |

18120 |

33273 |

<800 |

6400 |

60 |

10000 |

60 |

|

3 |

4.25 |

5.00 |

5.45 |

8 |

0.75 |

200 |

18120 |

26618 |

<800 |

6400 |

88 |

10000 |

75 |

|

3.5 |

4.75 |

5.50 |

6.03 |

8 |

0.75 |

200 |

18120 |

24021 |

<800 |

6400 |

99 |

10000 |

83 |

|

4 |

5.19 |

6.19 |

8.93 |

8 |

0.75 |

200 |

18120 |

16227 |

<800 |

6400 |

125 |

10000 |

123 |

|

5 |

6.31 |

7.31 |

10.69 |

8 |

0.75 |

200 |

18120 |

13558 |

<800 |

6400 |

156 |

10000 |

148 |

|

6 |

7.50 |

8.50 |

12.56 |

12 |

0.75 |

200 |

18120 |

17312 |

<800 |

6400 |

131 |

10000 |

116 |

|

8 |

9.38 |

10.62 |

19.47 |

12 |

0.88 |

320 |

25140 |

15496 |

<800 |

6400 |

205 |

10000 |

207 |

|

10 |

11.25 |

12.75 |

28.26 |

16 |

1.00 |

490 |

33060 |

18718 |

<800 |

6400 |

219 |

10000 |

262 |

|

12 |

13.50 |

15.00 |

33.56 |

16 |

1.13 |

710 |

43680 |

20826 |

<800 |

6400 |

319 |

15000 |

511 |

|

14 |

14.75 |

16.25 |

36.50 |

20 |

1.13 |

710 |

43680 |

23933 |

<800 |

6600 |

287 |

15000 |

445 |

|

16 |

16.75 |

18.50 |

48.42 |

20 |

1.25 |

1000 |

55740 |

23021 |

<800 |

6600 |

401 |

15000 |

652 |

|

18 |

19.25 |

21.00 |

55.29 |

24 |

1.25 |

1000 |

55740 |

24194 |

<800 |

6400 |

439 |

15000 |

620 |

|

20 |

21.00 |

23.00 |

69.08 |

24 |

1.25 |

1000 |

55740 |

19365 |

<800 |

6400 |

484 |

15000 |

775 |

|

24 |

25.25 |

27.25 |

82.43 |

24 |

1.50 |

1600 |

84300 |

24546 |

<800 |

6400 |

662 |

15000 |

978 |

Applications of Tongue & Groove Flanges

ASME B16.5 Groove and Tongue Flanges are known for their excellent performance and are typically designed to meet specific needs. We offer a wide range of Tongue & Groove Flanges through our global network of branches. These flanges are used in various industrial applications, including:

- Chemical Industry

- Plumbing

- Power Plants

- Food Processing Industry

- Structural Pipe

- Oil and Gas Pipelines

- Heating Systems

- Water Supply Systems

- Paper & Pulp Industry

- General Purpose Applications

- Fabrication Industry

Kaizen Steel Industries Export to

Burundi, Comoros, Djibouti, Eritrea, Ethiopia, Kenya, Madagascar, Malawi, Mauritius, Mayotte, Mozambique, Reunion, Rwanda, Seychelles, Somalia, Tanzania, United Republic of Uganda, Zambia, Zimbabwe, Angola, Cameroon, Central African Republic, Chad, Congo (Brazzaville), Congo, Democratic Republic of the Equatorial Guinea, Gabon, Sao Tome and Principe, Algeria, Egypt, Libyan Arab Jamahiriya, Morroco, South Sudan, Sudan, Tunisia, Western Sahara, Botswana, Lesotho, Namibia, South Africa, Swaziland, Benin, Burkina Faso, Cape Verde, Cote d\\’Ivoire (Ivory Coast), Gambia, Ghana, Guinea, Guinea-Bissau, Liberia, Mali, Mauritania, Niger, Nigeria, Saint Helena, Senegal, Sierra Leone, Togo

Anguilla, Antigua and Barbuda, Aruba, Bahamas, Barbados, Bonaire, Saint Eustatius and Saba, British Virgin Islands, Cayman Islands, Cuba, Curaçao, Dominica, Dominican Republic, Grenada, Guadeloupe, Haiti, Jamaica, Martinique, Monserrat, Puerto Rico, Saint-Barthélemy, St. Kitts and Nevis, Saint Lucia, Saint Martin, Saint Vincent and the Grenadines, Sint Maarten, Trinidad and Tobago, Turks and Caicos Islands, Virgin Islands (US), Belize, Costa Rica, El Salvador, Guatemala, Honduras, Mexico, Nicaragua, Panama, Argentina, Bolivia, Brazil, Chile, Colombia, Ecuador, Falkland Islands (Malvinas), French Guiana, Guyana, Paraguay, Peru, Suriname, Uruguay, Venezuela, Bermuda, Canada, Greenland, Saint Pierre and Miquelon, United States

Afghanistan, Armenia, Azerbaijan, Bangladesh, Bhutan, Brunei Darussalam, Cambodia, China, Georgia, Hong Kong, India, Indonesia, Japan, Kazakhstan, South Korea, Kyrgyzstan, Laos, Macao, Malaysia, Maldives, Mongolia, Myanmar (ex-Burma), Nepal, Phillipines, Singapore, Sri Lanka (ex-Ceilan), Taiwan, Tajikistan, Thailand, Timor Leste (West), Turkmenistan, Uzbekistan, Vietnam

Albania, Andorra, Belarus, Bosnia, Croatia, European Union, Faroe Islands, Gibraltar, Guerney and Alderney, Iceland, Jersey, Kosovo, Liechtenstein, Macedonia, Man, Island of Moldova, Monaco, Montenegro, Norway, Russia, San Marino, Serbia, Svalbard and Jan Mayen Islands, Switzerland, Turkey, Ukraine, Vatican City State (Holy See)

Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, United Kingdom

Bahrain, Iraq, Iran, Israel, Jordan, Kuwait, Lebanon, Oman, Palestine, Qatar, Saudi Arabia, Syria, United Arab Emirates, Yemen