Forged Fittings 45 Degree Socket

Weld Elbow (ASME B16.11)

Table of Content

- Uses of Socket Weld 45° Elbow

- Benefits of Forged Socket Weld 45° Elbow

- Features of Forged Socket Weld 45° Elbows

- Socket Weld 45 Elbow Specification

- Forged Socket Weld Elbow 45 Degree Material

- 45 Degree Socket Weld Elbow Types

- 45 Degree Socket Weld Elbow Dimensions

- 45° Short Radius Socket Weld Elbow 6000 LBS

- Forged Socket Weld 45° Elbow Applications

Socket Weld 45° Elbows are essential pipe fittings used to change the direction of fluid flow in a piping system by 45 degrees. They feature socket weld ends, which simplify installation and provide a secure connection.

Socket Weld 45° Elbows are compact in design and are used in various industries, including oil and gas, chemical processing, and power generation. They are particularly valuable in situations where precise directional changes are needed without extensive modifications to the piping.

Kaizen Steel Industries is a prominent supplier of a wide range of Socket Weld 45° Pipe Fittings to both global and domestic buyers. The company ensures high-quality production through rigorous stage-wise inspections, overseen by industry experts. Kaizen Steel Industries offers Forged Socket Weld 45° fittings at competitive rates, making us an attractive option for buyers seeking reliability and value.

Uses of Socket Weld 45° Elbow

Socket Weld 45° Elbows are designed to connect pipes or fittings at a 45-degree angle within a piping system. They are utilized in various applications where a smooth, gradual change in direction is needed, and are particularly valuable for:

- Water, Oil, and Gas Systems: They help in redirecting the flow in pipelines for these fluids.

- Steam Processes: Ideal for managing steam flow in power generation and industrial processes.

- Compact or Confined Spaces: Useful in systems where space is limited and a gradual change in direction is required without excessive modification.

Benefits of Forged Socket Weld 45° Elbow

Forged Socket Weld 45° Elbows offer several advantages due to their construction and design:

- Durability and Strength: Forged from high-quality materials, they are built to withstand demanding conditions and provide long-term performance.

- Leak-Free Connection: The socket weld ends ensure a secure and reliable connection that minimizes the risk of leaks.

- Efficient Flow: The 45-degree angle aids in maintaining smooth fluid flow, reducing pressure drop and turbulence.

- Easy Installation and Maintenance: Their design allows for straightforward installation and upkeep, making them a convenient choice for various applications.

Best Price and Features of Forged Socket Weld 45° Elbows

Socket Weld 45° Elbows come in various materials and specifications, each tailored for different industrial needs. Here are some key options and their attributes:

- Duplex Steel 45° Socket Weld Elbow: Known for its high strength and resistance to corrosion, these elbows are ideal for challenging environments. They offer good price value given their durability.

- MSS SP-79 and MSS SP-83 Socket Weld 45° Elbow: These conform to industry standards and are used in high-pressure applications. They provide reliable performance and durability at competitive prices.

- 45 Degree Elbow 3000LB Socket Weld: Designed for high-pressure systems, these elbows offer exceptional strength and can handle significant stress.

- Inconel Forged Socket Weld 45° Elbow: Made from Inconel, a high-performance alloy, these elbows are highly resistant to oxidation, corrosion, and high temperatures.

- Stockholder of 45° Socket Weld Elbow: Provides a wide range of elbow types and sizes, catering to various industrial requirements at competitive rates.

- BS3799 Socket Weld 45° Elbow Wholesaler: Offers elbows that meet BS3799 standards, ensuring quality and reliability in demanding applications.

- Hastelloy C22 45° Pipe Elbow: Known for its superior resistance to corrosion and high-temperature performance, ideal for harsh chemical environments.

- Copper Nickel 45° Socket Weld Pipe Elbow Exporter: Provides excellent resistance to seawater corrosion and is suited for marine applications.

- Alloy 20 45° Elbow Traders in India: Offers elbows made from Alloy 20, which are known for their resistance to acids and oxidation, suitable for various industrial processes.

The Forged Socket Weld 45° Elbow resists corrosion, pitting, oxidation, stress corrosion cracking, and crevice corrosion. It is known for its strong tensile strength and precise dimensions. It can handle heavy loads and performs well in high-temperature environments.

Socket Weld 45 Elbow Specification

| 45 Degree Socket Weld Elbow Dimensions | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Street Elbow Asme B16.11 Size | 1/2″NB TO 4″NB IN |

| Carbon Steel 45 Degree Sw Elbow Class | 3000 LBS, 6000 LBS, 9000 LBS |

| B16.11 Socket Weld 45 Elbow Type | Socket Weld (S/W) & SCREWED (SCRD) – NPT, BSP, BSPT |

| 45 Degree Socket Weld Elbow Form | 45 Deg Socket Weld Elbow, Long Radius Socket Weld 45 Deg Elbow, Short Radius 45 Deg Socket Weld elbow |

| Value Added Services: | Hot Dipped Galvanizing, Epoxy & FBE Coating, Electro Polish, Sand Blasting, Threading, Soldering |

| Production Grades: | Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low temperature Steel, Carbon Steel, Cupro Nickel |

Forged Socket Weld Elbow 45 Degree Material

| Carbon Steel 45 Degree Sw Elbow |

|

| Stainless Steel Socket Weld 45 Deg. Elbow |

|

| Alloy Steel 45 Degree Socket Weld Elbow |

|

| Titanium 45 Degree Socket Weld Elbow |

|

| Inconel 45 3000lb Socket Weld |

|

| Copper 45 Degree Socket Weld Elbow | T1, T2, C10100, C10200, C10300, C10400, C10500, C10700, C10800, C10910,C10920, TP1, TP2, C10930, C11000, C11300, C11400, C11500, C11600, C12000,C12200, C12300, TU1, TU2, C12500, C14200, C14420, C14500, C14510, C14520, C14530, C17200, C19200, C21000, C23000, C26000, C27000, C27400, C28000, C33000, C33200, C37000, C44300, C44400, C44500, C60800, C63020, C68700, C70400, C70600, C70620, C71000, C71500, C71520, C71640, etc |

| Copper Nickel 3000lb Socket Weld | Copper Nickel 90/10 (C70600 ), Cupro Nickel 70/30 (C71500), UNS C71640 |

| Brass 45° Short Radius Socket Weld Elbow | 3602 / 2604 / H59 / H62 / etc. |

| Hastelloy 45° Short Radius Socket Weld Elbow | Hastelloy C276 (UNS N10276), C22 (UNS N06022), C4, C2000, B2, B3, X |

| Monel 45 Degree Socket Weld Elbow | Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500) |

| Alloy 20 45° Socket Weld Elbow | Carpenter® 20 Alloy, Alloy 20Cb-3 |

| Aluminium 45° Short Radius Socket Weld Elbow | 5052 /6061/ 6063 / 2017 / 7075 / etc. |

| Nickel 45° Socket Weld Elbow | Nickel 200 Forged, Nickel 201 Forged |

| Duplex | S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Super Duplex 45° Short Radius Socket Weld Elbow | S32750 / S32760 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Incoloy 45° Socket Weld Elbow | Incoloy 800, Incoloy 800H, Incoloy 800HT (UNS N08800), Incoloy 825 (UNS N08825) |

| 254 Smo 45° Short Radius Socket Weld Elbow | SMO 254/6Mo, UNS S31254, DIN 1.4547 |

| Nimonic | Nimonic 75, Nimonic 80A, Nimonic 90 |

| Other 45° Socket Weld Elbow material | Tin bronze, Alumunum bronze, Lead bronze |

45 Degree Socket Weld Elbow Types

Class 3000 elbow, 45 degree, socket weld

Class 6000 elbow, 45 degree, socket weld

Class 9000 elbow, 45 degree, socket weld

B16.11 socket weld 45 degree elbow

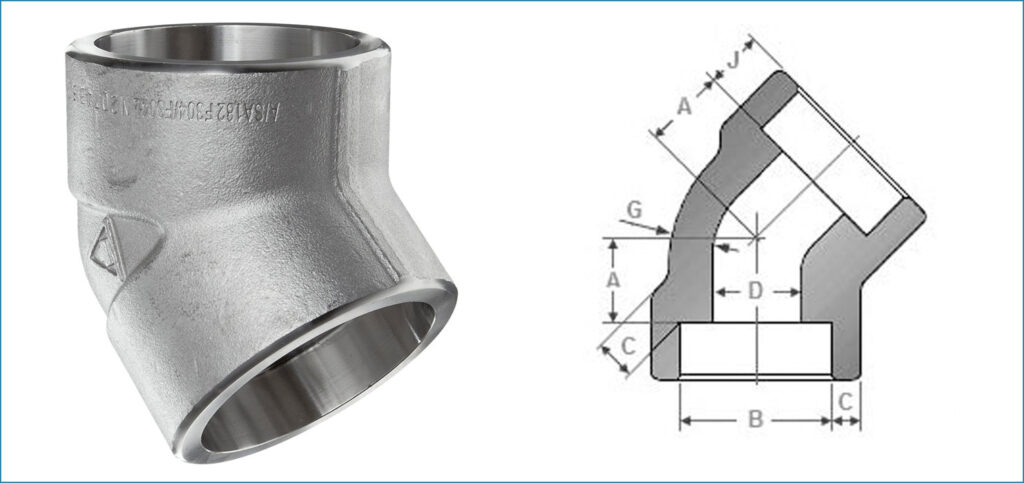

45 Degree Socket Weld Elbow Dimensions

| NPS | Socket Bore | Depth Socket | Bore diameter | Socket wall thickness | Body wall thickness | Center to bottom of socket A | |

| B | J | D | C | G | 45° | ||

| 1/2 | 21.95 21.70 | 10 | 16.6 15 | 4.65 4.10 | 3.75 | 11.5 | |

| 3/4 | 27.30 27.05 | 13 | 21.7 20.2 | 4.90 4.25 | 3.90 | 12.5 | |

| 1 | 34.05 33.80 | 13 | 27.4 25.9 | 5.70 5.00 | 4.55 | 14 | |

| 1¼ | 42.80 42.55 | 13 | 35.8 34.3 | 6.05 5.30 | 4.85 | 17 | |

| 1½ | 48.90 48.65 | 13 | 41.7 40.1 | 6.35 5.55 | 5.10 | 21 | |

| 2 | 61.35 61.10 | 16 | 53.5 51.7 | 6.95 6.05 | 5.55 | 25 | |

| 2½ | 74.20 73.80 | 16 | 64.2 61.2 | 8.75 7.65 | 7.00 | 29 | |

| 3 | 90.15 89.80 | 16 | 79.5 46.4 | 9.50 8.30 | 7.60 | 31.5 | |

| 4 | 115.80 115.45 | 19 | 103.8 100.7 | 10.70 9.35 | 8.55 | 41.5 | |

45° Short Radius Socket Weld Elbow 6000 LBS

| NPS | Socket Bore | Depth Socket | Bore diameter | Socket wall thickness | Body wall thickness | Center to bottom of socket A |

| B | J | D | C | G | 45° | |

| 1/2 | 21.95 21.70 | 10 | 12.5 11 | 5.95 5.20 | 4.80 | 12.5 |

| 3/4 | 27.30 27.05 | 13 | 16.3 14.8 | 6.95 6.05 | 5.55 | 14.5 |

| 1 | 34.05 33.80 | 13 | 21.5 19.9 | 7.90 6.95 | 6.35 | 17 |

| 1¼ | 42.80 42.55 | 13 | 30.2 28.7 | 7.90 6.95 | 6.35 | 21 |

| 1½ | 48.90 48.65 | 13 | 34.7 33.2 | 8.90 7.80 | 7.15 | 25 |

| 2 | 61.35 61.10 | 16 | 43.6 42.1 | 10.90 9.50 | 8.75 | 29 |

Forged Socket Weld 45° Elbow Applications

ASME B16.11 45° Socket Weld Pipe Fittings are designed to perform exceptionally well under various conditions. We provide a wide selection of these elbows through our global network of stock-keeping branches. They are used in different industries, including:

- Stainless Steel 45° Forged Elbow: For oil and gas pipelines

- 45° Forged Pipe Elbow: In the chemical industry

- Alloy Steel 45° Elbow: For plumbing applications

- Forged 45° Pipe Elbow: In heating systems

- 45° Forged Elbow: For water supply systems

- ANSI B16.9 Forged 45° Pipe Elbow: Used in power plants

- 45° Elbow: In the paper and pulp industry

- 45° Degree Elbow: For general-purpose applications

- Forged 45° Long Radius Elbow: In the fabrication industry

- 45° Forged Elbow: For food processing

- Forged 45° Short Radius Elbow: Used in structural piping

Kaizen Steel Industries Export to

Burundi, Comoros, Djibouti, Eritrea, Ethiopia, Kenya, Madagascar, Malawi, Mauritius, Mayotte, Mozambique, Reunion, Rwanda, Seychelles, Somalia, Tanzania, United Republic of Uganda, Zambia, Zimbabwe, Angola, Cameroon, Central African Republic, Chad, Congo (Brazzaville), Congo, Democratic Republic of the Equatorial Guinea, Gabon, Sao Tome and Principe, Algeria, Egypt, Libyan Arab Jamahiriya, Morroco, South Sudan, Sudan, Tunisia, Western Sahara, Botswana, Lesotho, Namibia, South Africa, Swaziland, Benin, Burkina Faso, Cape Verde, Cote d\\’Ivoire (Ivory Coast), Gambia, Ghana, Guinea, Guinea-Bissau, Liberia, Mali, Mauritania, Niger, Nigeria, Saint Helena, Senegal, Sierra Leone, Togo

Anguilla, Antigua and Barbuda, Aruba, Bahamas, Barbados, Bonaire, Saint Eustatius and Saba, British Virgin Islands, Cayman Islands, Cuba, Curaçao, Dominica, Dominican Republic, Grenada, Guadeloupe, Haiti, Jamaica, Martinique, Monserrat, Puerto Rico, Saint-Barthélemy, St. Kitts and Nevis, Saint Lucia, Saint Martin, Saint Vincent and the Grenadines, Sint Maarten, Trinidad and Tobago, Turks and Caicos Islands, Virgin Islands (US), Belize, Costa Rica, El Salvador, Guatemala, Honduras, Mexico, Nicaragua, Panama, Argentina, Bolivia, Brazil, Chile, Colombia, Ecuador, Falkland Islands (Malvinas), French Guiana, Guyana, Paraguay, Peru, Suriname, Uruguay, Venezuela, Bermuda, Canada, Greenland, Saint Pierre and Miquelon, United States

Afghanistan, Armenia, Azerbaijan, Bangladesh, Bhutan, Brunei Darussalam, Cambodia, China, Georgia, Hong Kong, India, Indonesia, Japan, Kazakhstan, South Korea, Kyrgyzstan, Laos, Macao, Malaysia, Maldives, Mongolia, Myanmar (ex-Burma), Nepal, Phillipines, Singapore, Sri Lanka (ex-Ceilan), Taiwan, Tajikistan, Thailand, Timor Leste (West), Turkmenistan, Uzbekistan, Vietnam

Albania, Andorra, Belarus, Bosnia, Croatia, European Union, Faroe Islands, Gibraltar, Guerney and Alderney, Iceland, Jersey, Kosovo, Liechtenstein, Macedonia, Man, Island of Moldova, Monaco, Montenegro, Norway, Russia, San Marino, Serbia, Svalbard and Jan Mayen Islands, Switzerland, Turkey, Ukraine, Vatican City State (Holy See)

Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, United Kingdom

Bahrain, Iraq, Iran, Israel, Jordan, Kuwait, Lebanon, Oman, Palestine, Qatar, Saudi Arabia, Syria, United Arab Emirates, Yemen

Request a Quote

Our Products

Related Products

SS Pipe Fittings Manufacturers

Know More

Carbon Steel Pipe Fittings

Know More

Stainless Steel Bends

Know More

Stainless Steel Equal Tee Elbow

Know More