ANSI / ASME B16.11

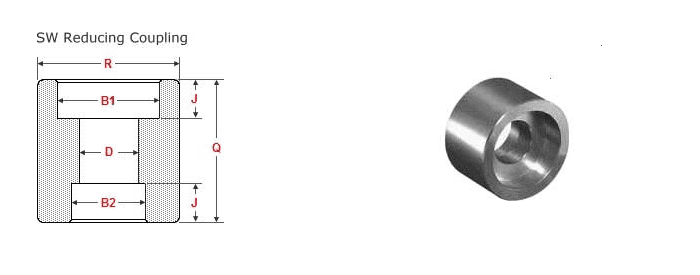

Socket Weld Reducing Coupling

A Socket Weld Reducing Coupling is a type of pipe connection where the pipe is inserted into a recessed area of a valve, fitting, or flange. Unlike buttweld fittings, Socket Weld Fittings are mostly used for smaller pipes, typically with a Nominal Diameter of NPS 2 or less.

To connect pipes to valves, fittings, or other pipe sections, fillet-type seal welds are used. Socket Welded Pipe Fittings Joints are a reliable choice when high leakage prevention and strong structural integrity are important factors.

Kaizen Steel Industries has over 10 years of experience in manufacturing forged fittings according to ASME B16.11 and MSS-SP-83 standards. The company is dedicated to providing high-quality products to customers at competitive prices by utilizing innovative production systems and processes.

An ASME B16.11 Coupling is a fitting used to connect two pipes. If the pipes are of different sizes, the 3000 Lb Socket Weld Coupling is called a reducer, reducing coupling, or adapter. There are two types of Socket Weld Couplings in Class 150: regular and slip.

A regular Carbon Steel Socket Weld Pipe Fittings has a small ridge or stop inside. This ridge helps prevent one pipe from being inserted too far, which could cause the other pipe segment to be inserted too little. This ensures a secure connection. On the other hand, a slip Forged Pipe Coupling, sometimes known as a repair coupling, doesn’t have this internal stop. This allows it to be easily slipped into tight spaces.

For example, a slip Socket Weld Coupling Class 3000 can be used to fix a pipe with a small leak caused by corrosion or freezing, or when a pipe has been temporarily cut. Since the stop is missing in this type of coupling, the installer needs to carefully measure and position the slip coupling correctly to ensure it is placed in the right spot.

Socket Weld Coupling Stainless Steel Pipe Fittings are forged products that can be classified by their pressure and temperature ratings. The dimensions of Socket Weld Forged Couplings range from NPS 1/8 inch to 4 inches. We have Socket Weld Half Coupling fittings in stock with three different pressure-temperature ratings.

These 3000 & 6000 class fittings are available in both Threaded and Socket Weld types, including the Socket Weld Coupling.

Kaizen Steel Industries is known as a leading manufacturer, exporter, and supplier of a wide range of Reducing Couplings, including Socket Weld Reducing Couplings.

Socket Weld Reducing Coupling Specification

| Reducing Coupling Specification | ASTM A182 / ASTM SA182, ASTM A105 / ASME SA105, ASTM A350 / ASME SA350, ASTM A694 / ASME SA694, ASTM B462 / ASME SB462 / ASTM B564 / ASME SB564, ASTM B151 / ASME SB151, ASTM B381 / ASME SB381 |

| Reducing Coupling Manufacturing Process | Forging / Socket / Threaded / Screwed |

| Reducing Coupling Available Other Grades | Stainless Steel – F304, F304L, F304H, F310s, F316, F316L, F317L, F321, F347, F904L, F410, F446 etc. Carbon Steel – 105N, LF2, F42, F46, F52, F56, F60, F65 etc. Alloy Steel – F5, F9, F11, F22, F91, 4140, Class 1, 2, 3 etc. Duplex and Super Duplex – F51, F53, F55, UNS N031803, UNS N032750, UNS N032760 etc. Inconel – 600, 601, 625, 718, UNS N06600, UNS N06601, UNS N06625, UNS N07718 etc. Incoloy – 800, 800H, 800HT, 825, UNS N08800, UNS N08810, UNS N08811, UNS N08825 etc. Monel – 400, UNS N04400 etc. Hastelloy – C276, C22, UNS N010276, UNS N06022 etc. Titanium – Grade 2, Grade 3, UNS R50400, UNS R56200 etc. Copper Nickel – 90/10, 70/30, UNS C71500, UNS C70600 etc. Other – Alloy 20, SMO 254, F44, 6 Moly, UNS N08020, UNS N031254 etc. |

| Reducing Coupling Outer Diameter | 1/8″ NB TO 4″ NB (DN6 to DN100) |

| Reducing Coupling Pressure Class | 2000 LBS, 3000 LBS, 6000 LBS ,9000 LBS or As Per Custom Requirement |

| Reducing Elbow Other Fittings Types | 45 Degree Elbow, 90 Degree Elbow, Lateral, Tee, Reducer Insert, Full Coupling, Half Coupling, Reducing Coupling, Cap, Union, Cross, Boss, Plug, Bushing etc. |

| Reducing Coupling Dimension | ASME 16.11 – Socket Welding and Threaded Forged Fittings MSS SP-79 – Socket Welding Reducer Inserts MSS SP-83 – Socket Weld Union MSS SP-95 – Swage(d) Nipples and Bull Plugs BS 3799 – Specification for Steel Pipe Fittings, Screwed and Socket-welding for the petroleum industry. |

| Reducing Coupling Other Testing | Tensile, Hardness Test, Chemical Analysis – Spectro Analysis, Positive Material Identification – PMI Testing, Flattening Test, Micro and Macro Test, Pitting Resistance Test, Flaring Test, Intergranular Corrosion (IGC) Test, NACE MR0175, Ultrasound Test, ASTM A262 Practice E, Charpy Impact Test, Grain Size, Dye Penetrant Test etc. |

| Reducing Coupling Packaging | Carrate / Wooden Pallet / Wooden box-a |

| Reducing Coupling Shipment & Transportation | By Road – Truck / Train Partial Load, Full Load, By Sea – Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air – Freighter Civil Passenger and Cargo Planes |

| Reducing Coupling Material Test Certificate | Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS, Bureau of Indian Standards BIS Approved ETC |

Reducing Coupling Material and Grades

| Material Type | Specifications |

|---|---|

| Stainless Steel Forged Reducing Coupling | ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F454L, ASTM A312/A403 TP304, TP304L, TP316, TP316L |

| Duplex & Super Duplex Forged Reducing Coupling | ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950 |

| Carbon Steel Forged Reducing Coupling | ASTM/ASME A 105, ASTM/ASME A 350 LF 2, ASTM/ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C, API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70, ASTM/ASME A 691 GR A, B & C |

| Alloy Steel Forged Reducing Coupling | ASTM/ASME A 182, ASTM/ASME A 335, ASTM/ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM/ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91 |

| Copper Alloy Forged Reducing Coupling | ASTM/ASME SB 111 UNS NO. C 10100, C 10200, C 10300, C 10800, C 12000, C 12200, C 70600, C 71500, ASTM/ASME SB 466 UNS NO. C 70600 (CU-NI-45/10), C 71500 (CU-NI-70/30) |

| Nickel Alloy Forged Reducing Coupling | ASTM/ASME SB 336, ASTM/ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200), UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400), UNS 8020 (ALLOY 20/20 CB 3), UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276) |

Manufacturing Standards of Pipe Coupling Socket Weld

| ASME B16.11 Coupling: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

ASME B16.11 Socket Weld Coupling Types

Class 3000 elbow, socket weld half coupling

Class 6000 elbow, socket weld half coupling

Class 9000 elbow, socket weld half coupling

B16.11 socket weld half coupling

Dimensions of Socket Weld Reducing Coupling ASME B16.11 - NPS 1/2 to 2 - Class 3000

| NPS | Socket Bore | Depth Socket J | Bore dia | ||||

| B1 | B2 | B1 | B2 | D | |||

| 3/4 | – | 1/2 | 27.30 27.05 | 21.95 21.70 | 13 | 10 | 16.6 15 |

| 1 | – | 3/4 | 34.05 33.80 | 27.30 27.05 | 13 | 13 | 21.7 20.2 |

| 1 | – | 1/2 | 34.05 33.80 | 21.95 21.70 | 13 | 10 | 16.6 15 |

| 1.1/4 | – | 1 | 42.80 42.55 | 34.05 33.80 | 13 | 13 | 27.4 25.9 |

| 1.1/2 | – | 1 | 48.90 48.65 | 34.05 33.80 | 13 | 13 | 27.4 25.9 |

| 1.1/2 | – | 3/4 | 48.90 48.65 | 27.30 27.05 | 13 | 13 | 21.7 20.2 |

| 1.1/2 | – | 1/2 | 48.90 48.65 | 21.95 21.70 | 13 | 10 | 16.6 15 |

| 2 | – | 1.1/2 | 61.35 61.10 | 48.90 48.65 | 16 | 13 | 41.7 40.1 |

| 2 | – | 1 | 74.20 73.80 | 34.05 33.80 | 16 | 13 | 27.4 25.9 |

| NPS | Length Coupling | Diameter Coupling | |||||

| Q | R | ||||||

| 3/4 | – | 1/2 | 35 | 36 | |||

| 1 | – | 3/4 | 38.1 | 45.2 | |||

| 1 | – | 1/2 | 38.1 | 45.2 | |||

| 1.1/4 | – | 1 | 38.1 | 55.1 | |||

| 1.1/2 | – | 1 | 38.1 | 60 | |||

| 1.1/2 | – | 3/4 | 38.1 | 60 | |||

| 1.1/2 | – | 1/2 | 38.1 | 60 | |||

| 2 | – | 1.1/2 | 51.3 | 74.9 | |||

| 2 | – | 1 | 51.3 | 74.9 | |||

Dimensions of Socket Weld Reducing Coupling ASME B16.11 - NPS 1/2 to 2 - Class 6000

| NPS | Socket Bore | Depth Socket J | Bore dia | ||||

| B1 | B2 | B1 | B2 | D | |||

| 3/4 | – | 1/2 | 27.30 27.05 | 21.95 21.70 | 13 | 10 | 12.5 11 |

| 1 | – | 3/4 | 34.05 33.80 | 27.30 27.05 | 13 | 13 | 16.3 14.8 |

| 1 | – | 1/2 | 34.05 33.80 | 21.95 21.70 | 13 | 10 | 12.5 11 |

| 1.1/4 | – | 1 | 42.80 42.55 | 34.05 33.80 | 13 | 13 | 21.5 19.9 |

| 1.1/2 | – | 1 | 48.90 48.65 | 34.05 33.80 | 13 | 13 | 21.5 19.9 |

| 1.1/2 | – | 3/4 | 48.90 48.65 | 27.30 27.05 | 13 | 13 | 16.3 14.8 |

| 1.1/2 | – | 1/2 | 48.90 48.65 | 21.95 21.70 | 13 | 10 | 12.5 11 |

| 2 | – | 1.1/2 | 61.35 61.10 | 48.90 48.65 | 16 | 13 | 34.7 33.2 |

| 2 | – | 1 | 74.20 73.80 | 34.05 33.80 | 16 | 13 | 21.5 19.9 |

| NPS | Length Coupling | Diameter Coupling | |||||

| Q | R | ||||||

| 3/4 | – | 1/2 | 35 | 40.1 | |||

| 1 | – | 3/4 | 38.1 | 50 | |||

| 1 | – | 1/2 | 38.1 | 50 | |||

| 1.1/4 | – | 1 | 38.1 | 57.9 | |||

| 1.1/2 | – | 1 | 38.1 | 65 | |||

| 1.1/2 | – | 3/4 | 38.1 | 65 | |||

| 1.1/2 | – | 1/2 | 38.1 | 65 | |||

| 2 | – | 1.1/2 | 51.3 | 82 | |||

| 2 | – | 1 | 51.3 | 82 | |||

Reducing Coupling Applications

- Oil and Gas Industries

- Food Processing Industries

- Equipment

- Pipelines

- Power Industries

- Shipbuilding Industries

- Paper Industries

- Cement Industries

- Chemical Industries

Kaizen Steel Industries Export to

Burundi, Comoros, Djibouti, Eritrea, Ethiopia, Kenya, Madagascar, Malawi, Mauritius, Mayotte, Mozambique, Reunion, Rwanda, Seychelles, Somalia, Tanzania, United Republic of Uganda, Zambia, Zimbabwe, Angola, Cameroon, Central African Republic, Chad, Congo (Brazzaville), Congo, Democratic Republic of the Equatorial Guinea, Gabon, Sao Tome and Principe, Algeria, Egypt, Libyan Arab Jamahiriya, Morroco, South Sudan, Sudan, Tunisia, Western Sahara, Botswana, Lesotho, Namibia, South Africa, Swaziland, Benin, Burkina Faso, Cape Verde, Cote d\\’Ivoire (Ivory Coast), Gambia, Ghana, Guinea, Guinea-Bissau, Liberia, Mali, Mauritania, Niger, Nigeria, Saint Helena, Senegal, Sierra Leone, Togo

Anguilla, Antigua and Barbuda, Aruba, Bahamas, Barbados, Bonaire, Saint Eustatius and Saba, British Virgin Islands, Cayman Islands, Cuba, Curaçao, Dominica, Dominican Republic, Grenada, Guadeloupe, Haiti, Jamaica, Martinique, Monserrat, Puerto Rico, Saint-Barthélemy, St. Kitts and Nevis, Saint Lucia, Saint Martin, Saint Vincent and the Grenadines, Sint Maarten, Trinidad and Tobago, Turks and Caicos Islands, Virgin Islands (US), Belize, Costa Rica, El Salvador, Guatemala, Honduras, Mexico, Nicaragua, Panama, Argentina, Bolivia, Brazil, Chile, Colombia, Ecuador, Falkland Islands (Malvinas), French Guiana, Guyana, Paraguay, Peru, Suriname, Uruguay, Venezuela, Bermuda, Canada, Greenland, Saint Pierre and Miquelon, United States

Afghanistan, Armenia, Azerbaijan, Bangladesh, Bhutan, Brunei Darussalam, Cambodia, China, Georgia, Hong Kong, India, Indonesia, Japan, Kazakhstan, South Korea, Kyrgyzstan, Laos, Macao, Malaysia, Maldives, Mongolia, Myanmar (ex-Burma), Nepal, Phillipines, Singapore, Sri Lanka (ex-Ceilan), Taiwan, Tajikistan, Thailand, Timor Leste (West), Turkmenistan, Uzbekistan, Vietnam

Albania, Andorra, Belarus, Bosnia, Croatia, European Union, Faroe Islands, Gibraltar, Guerney and Alderney, Iceland, Jersey, Kosovo, Liechtenstein, Macedonia, Man, Island of Moldova, Monaco, Montenegro, Norway, Russia, San Marino, Serbia, Svalbard and Jan Mayen Islands, Switzerland, Turkey, Ukraine, Vatican City State (Holy See)

Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, United Kingdom

Bahrain, Iraq, Iran, Israel, Jordan, Kuwait, Lebanon, Oman, Palestine, Qatar, Saudi Arabia, Syria, United Arab Emirates, Yemen

Request a Quote

Our Products

Related Products

SS Pipe Fittings Manufacturers

Know More

Carbon Steel Pipe Fittings

Know More

Stainless Steel Bends

Know More

Stainless Steel Equal Tee Elbow

Know More