Forged Fittings ASME B16.11

Threaded Equal Tee Fittings

Kaizen Steel Industries is a renowned manufacturer of ASME B16.11 Threaded Tees, known for their resistance to chemical corrosion and oxidation. These tees offer high stress-rupture effectiveness and low creep rates at elevated temperatures after suitable heat treatment. The Threaded Equal Tee is designed to either combine or split fluid flow and features uniform inlet and outlet sizes.

Our Threaded Tee Fittings are utilized across various industries, including chemical processing, oil refineries, petrochemical, and more. We provide Forged Threaded Tees in customized sizes as per customer requirements and adhere to ASME B16.11 and BS 3799 standards. This standard covers pressure-temperature ratings, dimensions, marking, tolerances, and material requirements.

Threaded Tee Fittings are among the most commonly used pipe fittings, designed to combine or divide fluid flow efficiently. Our ASTM A182 SS Threaded Tees come with options including female thread sockets, solvent-weld sockets, opposed solvent-weld sockets, and a female-threaded side outlet.

The Threaded Equal Tee can connect pipes of varying diameters or change the direction of a pipe run, making it versatile for various applications. At Kaizen Steel Industries, we offer a diverse stock of Forged Threaded Tees produced in different materials, sizes, and finishes to meet your specific needs.

Our inventory includes Alloy Steel Forged Screwed Tees, which are also suitable for transporting two-fluid mixtures. Tees are categorized into equal or unequal sizes based on their three connections, with equal tees being the most commonly produced.

We specialize in supplying Threaded Equal Tees in three pressure ratings: Class 2000, Class 3000, and Class 6000, all available at competitive prices in China. For detailed dimensions, refer to the Threaded Pipe Tee Dimensions Chart before purchasing.

Threaded Tee Specification

| Dimensions | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Size | 1/8″~4″ (DN6~DN100) |

| Class | 3000 LBS, 6000 LBS, 9000 LBS |

| Type | Socket Weld (S/W) & SCREWED (SCRD) – NPT, BSP, BSPT |

| Form | Threaded Tee, Threaded Pipe Tee, Threaded Equal Tee |

| Value Added Services: | Hot Dipped Galvanizing, Epoxy & FBE Coating, Electro Polish, Sand Blasting, Threading, Soldering |

| Production Grades: | Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low temperature Steel, Carbon Steel, Cupro Nickel |

Manufacturing Standards of Threaded Equal Tee

| ASME: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

ASME B16.11 Threaded Tee Material Grades

| Material Type | Specifications |

|---|---|

| Stainless Steel Forged Threaded Tee | ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F904L, ASTM A312/A403 TP304, TP304L, TP316, TP316L |

| Duplex & Super Duplex Steel Forged Threaded Equal Tee | ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950 |

| Carbon Steel Forged Threaded Tee | ASTM/ASME A 105, ASTM/ASME A 350 LF 2, ASTM/ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C, API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70, ASTM/ASME A 691 GR A, B & C |

| Alloy Steel Forged Threaded Equal Tee | ASTM/ASME A 182, ASTM/ASME A 335, ASTM/ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM/ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91 |

| Copper Alloy Steel Forged Threaded Tee | ASTM/ASME SB 111 UNS NO. C 10100, C 10200, C 10300, C 10800, C 12000, C 12200, C 70600, C 71500, ASTM/ASME SB 466 UNS NO. C 70600 (CU-NI-90/10), C 71500 (CU-NI-70/30) |

| Nickel Alloy Forged Threaded Equal Tee | ASTM/ASME SB 336, ASTM/ASME SB 564/160/163/472, UNS 2200 (Nickel 200), UNS 2201 (Nickel 201), UNS 4400 (Monel 400), UNS 8020 (Alloy 20/20 CB 3), UNS 8825 (Inconel 825), UNS 6600 (Inconel 600), UNS 6601 (Inconel 601), UNS 6625 (Inconel 625), UNS 10276 (Hastelloy C 276) |

ASME B16.11 Threaded Tee Types

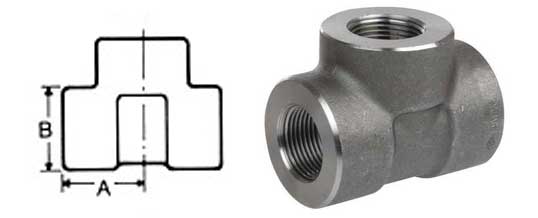

Class 3000 elbow, Threaded Tee

Class 6000 elbow, Threaded Tee

Class 9000 elbow, Threaded Tee

B16.11 Threaded Tee

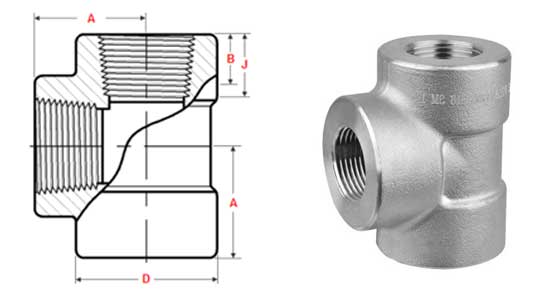

Threaded Tee Dimensions

| NPS | Min Length of Thread | Outside Dia of Band D | Center to End A | Min WT | |

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 33 | 28 | 3.18 |

| 3/4 | 12.7 | 13.9 | 38 | 33 | 3.18 |

| 1 | 14.7 | 17.3 | 46 | 38 | 3.68 |

| 1.1/4 | 17 | 18 | 56 | 44 | 3.89 |

| 1.1/2 | 17.8 | 18.4 | 62 | 51 | 4.01 |

| 2 | 19 | 19.2 | 75 | 60 | 4.27 |

| 2.1/2 | 23.6 | 28.9 | 92 | 76 | 5.61 |

| 3 | 25.9 | 30.5 | 109 | 86 | 5.99 |

| 4 | 27.7 | 33 | 146 | 106 | 6.55 |

ASME B16.11 Threaded Tee Weight Chart

| Class 2000 | Nominal Pipe Size | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| B | – | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/16 | 4 5/16 | 5 3/4 | |

| F | – | 3/4 | 3/4 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 2 1/16 | 2 1/2 | 3 1/8 | |

| Wt | – | 0.188 | 0.236 | 0.435 | 0.74 | 1.058 | 1.375 | 1.74 | 2.883 | 7.75 | 11.313 | 19.125 | |

| Class 3000 | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | |

| B | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 6 | |

| F | 3/4 | 3/4 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 1 3/4 | 2 1/16 | 2 1/2 | 3 1/8 | |

| Wt | 0.25 | 0.29 | 0.5 | 0.75 | 1.188 | 1.988 | 2.235 | 3 | 4.93 | 7.375 | 13.588 | 19.063 | |

| Class 6000 | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | |

| B | 1 1/6 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 5 3/4 | – | |

| F | 3月4日 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 1 3/4 | 2 1/16 | 2 1/2 | 3 1/8 | – | |

| Wt | 0.25 | 0.64 | 0.5 | 1.438 | 2.188 | 2.785 | 4.688 | 5.75 | 9.5 | 15 | 30.563 | – | |

Reducing Tee Socket Weld Class 3000 Weight

| (Normal Pipe Size) NPS | B | L1 | C | G | D | A | Weight In KG |

|---|---|---|---|---|---|---|---|

| inch | mm | socket weld | mm | mm | mm | mm | ~kg/pce |

| 1/4 3/8 1/2 3/4 | 14.20 17.60 21.80 27.20 | 9.53 9.53 9.53 12.50 | 3.30 3.51 4.09 4.27 | 3.02 3.20 3.73 3.91 | 8.86 12.14 15.42 20.55 | 11.11 13.49 15.88 19.05 | 0.11 0.16 0.34 0.41 |

| 1 1¼ 1½ 2 | 33.90 42.70 48.80 61.20 | 12.50 12.50 12.50 16.00 | 4.98 5.28 5.54 6.05 | 4.55 4.85 5.08 5.54 | 26.26 34.67 40.51 52.12 | 22.23 26.99 31.75 38.10 | 0.65 0.95 1.33 2.20 |

Applications of ASME B16.11 Forged Threaded/Screwed Equal Tee

- Oil & Gas Pipelines: Stainless Steel for reliable connections.

- Chemical Industry: Efficient fluid and chemical transport.

- Plumbing: Alloy Steel for durability.

- Heating Systems: Forged Screwed for robust performance.

- Water Supply Systems: Ensures system integrity.

- Power Plants: ANSI B16.11 for various components.

- Paper & Pulp Industry: Supports material transport.

- General Purpose: Versatile industrial use.

- Fabrication Industry: Essential for structural integrity.

- Food Processing: Sanitary transport of food products.

- Structural Pipes: Reliable connections for strong structures.

Kaizen Steel Industries Export to

Burundi, Comoros, Djibouti, Eritrea, Ethiopia, Kenya, Madagascar, Malawi, Mauritius, Mayotte, Mozambique, Reunion, Rwanda, Seychelles, Somalia, Tanzania, United Republic of Uganda, Zambia, Zimbabwe, Angola, Cameroon, Central African Republic, Chad, Congo (Brazzaville), Congo, Democratic Republic of the Equatorial Guinea, Gabon, Sao Tome and Principe, Algeria, Egypt, Libyan Arab Jamahiriya, Morroco, South Sudan, Sudan, Tunisia, Western Sahara, Botswana, Lesotho, Namibia, South Africa, Swaziland, Benin, Burkina Faso, Cape Verde, Cote d\\’Ivoire (Ivory Coast), Gambia, Ghana, Guinea, Guinea-Bissau, Liberia, Mali, Mauritania, Niger, Nigeria, Saint Helena, Senegal, Sierra Leone, Togo

Anguilla, Antigua and Barbuda, Aruba, Bahamas, Barbados, Bonaire, Saint Eustatius and Saba, British Virgin Islands, Cayman Islands, Cuba, Curaçao, Dominica, Dominican Republic, Grenada, Guadeloupe, Haiti, Jamaica, Martinique, Monserrat, Puerto Rico, Saint-Barthélemy, St. Kitts and Nevis, Saint Lucia, Saint Martin, Saint Vincent and the Grenadines, Sint Maarten, Trinidad and Tobago, Turks and Caicos Islands, Virgin Islands (US), Belize, Costa Rica, El Salvador, Guatemala, Honduras, Mexico, Nicaragua, Panama, Argentina, Bolivia, Brazil, Chile, Colombia, Ecuador, Falkland Islands (Malvinas), French Guiana, Guyana, Paraguay, Peru, Suriname, Uruguay, Venezuela, Bermuda, Canada, Greenland, Saint Pierre and Miquelon, United States

Afghanistan, Armenia, Azerbaijan, Bangladesh, Bhutan, Brunei Darussalam, Cambodia, China, Georgia, Hong Kong, India, Indonesia, Japan, Kazakhstan, South Korea, Kyrgyzstan, Laos, Macao, Malaysia, Maldives, Mongolia, Myanmar (ex-Burma), Nepal, Phillipines, Singapore, Sri Lanka (ex-Ceilan), Taiwan, Tajikistan, Thailand, Timor Leste (West), Turkmenistan, Uzbekistan, Vietnam

Albania, Andorra, Belarus, Bosnia, Croatia, European Union, Faroe Islands, Gibraltar, Guerney and Alderney, Iceland, Jersey, Kosovo, Liechtenstein, Macedonia, Man, Island of Moldova, Monaco, Montenegro, Norway, Russia, San Marino, Serbia, Svalbard and Jan Mayen Islands, Switzerland, Turkey, Ukraine, Vatican City State (Holy See)

Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, United Kingdom

Bahrain, Iraq, Iran, Israel, Jordan, Kuwait, Lebanon, Oman, Palestine, Qatar, Saudi Arabia, Syria, United Arab Emirates, Yemen

Request a Quote

Our Products

Related Products

SS Pipe Fittings Manufacturers

Know More

Carbon Steel Pipe Fittings

Know More

Stainless Steel Bends

Know More

Stainless Steel Equal Tee Elbow

Know More