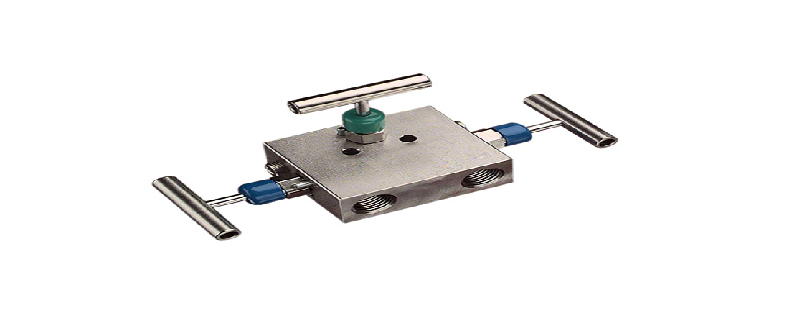

Manifold Valves

Chrome Moly Manifold Valves, Alloy Steel 2 Way Manifold Valve, Alloy Steel Manifold Valve, Chromium Molybdenum Valve Manifold, Cr-Mo Instrument Manifold Valves Suppliers, Alloy Steel 3 Way Manifold Valves, Alloy Steel Manifold Valves, Alloy Steel 5 Way Manifold Valves Manufacturers in Mumbai, India.

Kaizensteels is a leading supplier, exporter, and reliable manufacturer of high-quality Alloy Steel Manifold Valves. We proudly introduce our top-tier products to buyers worldwide, specializing in producing valves using advanced technology and modern machinery. Our team of trained professionals ensures rigorous quality checks at every stage of manufacturing to maintain high standards.

Customers globally prefer our valves for their unique features, including excellent finishing, precise dimensions, and high performance. We also offer customized valves in various sizes, shapes, and thicknesses to meet specific customer requirements. The raw materials we use are sourced from trusted vendors and undergo strict quality testing by our skilled team. Our products are continually updated to align with customer demands and market trends.

Alloy steel is our primary choice for manufacturing these valves due to its superior strength, durability, and reliability. This type of steel contains alloying elements like manganese, silicon, titanium, copper, chromium, and aluminum, which enhance its mechanical properties. The result is valves that can withstand high pressure and temperature conditions, offering exceptional tensile strength, yield strength, and resistance to corrosion, pitting, and stress cracking.

To ensure the valves’ quality is preserved during transportation, we pack them in sturdy wooden crates and boxes, wrapped in poly bags for added protection. We also provide relevant shipping documents to assure buyers of the product’s condition upon delivery.

We conduct various material tests to guarantee the valves’ strict quality and efficiency. These tests include mechanical tests, hardness tests, pitting resistance tests, PMI tests, IGC tests, and flaring tests. Additionally, we provide clients with necessary test certifications, such as MTC reports in accordance with EN 10204, radiography test reports, raw material reports, and other essential certifications.

Specification of Manifold Valve

| Product Name: | Manifold Valves / SS304/ 316L Manifold Valves |

| SS304/ 316L Manifold Valves Design: | Forged Body with Inline/Straight or Angle Pattern, Integral Bonnet Design |

| SS304/ 316L Manifold Valves available Size: | 1/8 to 1”, Custom Sizes available on request |

| Connection | Thread, Weld or Tube End |

| Flow Pattern: | Straight/ Angle |

| Power: | Manual |

| Working Pressure: | Up to 6000 PSIG, Manifold Valve Manufacturer in india are also available that can handle higher pressure

|

| Testing: | 100% Factory Tested |

| Manifold Valves Material: | SS 316, SS 304, C.S, F11, Hastelloy, Monel 400 |

| Stem: | Vee Steam is standard for pressure tightness even at elevated temperatures. Regulating Stem and Soft-seat Stem are optional |

| Temperature Rating: |

|

| Packing: | PTFE, Grafoil, PEEK/ PCTFE |

| End Connection: | Male and Female NPT, BSPT, Socket Weld (SW) or Dual Ferrule Tube Connections, Male to Female, Female to Female |

| Testing and Inspection: | Manufacturer Test Certificate as per EN 10204 / 3.1, Raw Materials Certificate, Third Party Inspection, Buyer Inspection |

Features of Manifold Valve Manufacturers in India

Here are some common features offered by manifold valve manufacturers in India:

- Material Variety: Available in a range of materials to suit different applications and environments.

- Low Operating Torques: Designed for ease of operation with minimal effort.

- High Pressure Rating: Capable of withstanding pressures up to 15,000 psi, making them suitable for demanding applications.

- Compact Design: Engineered with a space-saving design without compromising on performance.

- Versatile End Connections: Offers a variety of end connections, including Male/Female NPT, BSPT, and BSPP, to fit different piping requirements.

- Dust Cap Provided: Equipped with dust caps to protect the valves from contaminants and ensure longevity.

- Factory Tested: Each valve undergoes rigorous testing at the factory to ensure reliable performance before delivery.

Product Range For Cast And Forged Swing Check Valves

| Valve Type | Class Rating | Size Range | Shell Material As Per Specification |

| Swing Check | 150# | 2″ to 36″ | ASTM A216 Gr. WCB ASTM A217 Gr. WC1 ASTM A217 Gr. WC6 ASTM A217 Gr. WC9 ASTM A217 Gr. C5 ASTM A217 Gr. C12 ASTM A351 Gr. F8 ASTM A351 Gr. F3 ASTM A351 Gr. F8M ASTM A351 Gr. CF3M ASTM A351 Gr. CN7M ASTM A351 Gr. CF8C ASTM A351 Gr. CD4Mcu ASTM A351 Gr. CK3MCuN ASTM A352 Gr. LCA ASTM A352 Gr. LCB ASTM A352 Gr. LCC ASTM A494 Gr. CW6MC ASTM A494 Gr. CW2M ASTM A494 Gr. CW2M ASTM A494 Gr. CY40 ASTM A494 Gr. CU5MCuC ASTM A995 Gr. 1A ASTM A995 Gr. 4A ASTM A995 Gr. 5A ASTM A995 Gr. 6A NACE malt. Grade to NACE MR0175/NACE MR |

| Swing Check | 300# | 2″ to 36″ | |

| Swing Check | 600# | 2″ to 32″ | |

| Swing Check | 800# | 1/2″ to 2″ | |

| Swing Check – PRESSURE SEA L | 900# | 1/2″ to 20″ | |

| SWING CHECK – PRESSURE SEA L | 1500# | 1/2″ to 20″ | |

Note :

| |||

Manifold Valves Standards

| Design Standard | BS 1868 |

| Testing Standard | BS EN 12266 – 1 |

| Face To Face | ASME B 16.10 |

| End Connection | Flanged End – ASME B 16.5 Butt Weld End – ASME B 16.25 |

| Pressure – Temperature Chart | ASME B 16.34 |

Manifold valves Material

| STRUCTURE | End Connection | Flanged End Raised Face, Butt Weld End, RTJ,. ETC |

| MATERIAL | Shell | WCB, WC1, WC6, WC9, LCB, LCC, LC3, C5, C12, CF8, CF8M, CF3, CF3M, CF8C, CN7M, CD4MCu, Hastelloy, Inconel, Duplex Stainless Steel |

| Trim | 13% Cr Steel, 304 , 304L, 316, 316L, 321, 347, F51, Monel |

Kaizen Steel Industries Export to

Burundi, Comoros, Djibouti, Eritrea, Ethiopia, Kenya, Madagascar, Malawi, Mauritius, Mayotte, Mozambique, Reunion, Rwanda, Seychelles, Somalia, Tanzania, United Republic of Uganda, Zambia, Zimbabwe, Angola, Cameroon, Central African Republic, Chad, Congo (Brazzaville), Congo, Democratic Republic of the Equatorial Guinea, Gabon, Sao Tome and Principe, Algeria, Egypt, Libyan Arab Jamahiriya, Morroco, South Sudan, Sudan, Tunisia, Western Sahara, Botswana, Lesotho, Namibia, South Africa, Swaziland, Benin, Burkina Faso, Cape Verde, Cote d\\’Ivoire (Ivory Coast), Gambia, Ghana, Guinea, Guinea-Bissau, Liberia, Mali, Mauritania, Niger, Nigeria, Saint Helena, Senegal, Sierra Leone, Togo

Anguilla, Antigua and Barbuda, Aruba, Bahamas, Barbados, Bonaire, Saint Eustatius and Saba, British Virgin Islands, Cayman Islands, Cuba, Curaçao, Dominica, Dominican Republic, Grenada, Guadeloupe, Haiti, Jamaica, Martinique, Monserrat, Puerto Rico, Saint-Barthélemy, St. Kitts and Nevis, Saint Lucia, Saint Martin, Saint Vincent and the Grenadines, Sint Maarten, Trinidad and Tobago, Turks and Caicos Islands, Virgin Islands (US), Belize, Costa Rica, El Salvador, Guatemala, Honduras, Mexico, Nicaragua, Panama, Argentina, Bolivia, Brazil, Chile, Colombia, Ecuador, Falkland Islands (Malvinas), French Guiana, Guyana, Paraguay, Peru, Suriname, Uruguay, Venezuela, Bermuda, Canada, Greenland, Saint Pierre and Miquelon, United States

Afghanistan, Armenia, Azerbaijan, Bangladesh, Bhutan, Brunei Darussalam, Cambodia, China, Georgia, Hong Kong, India, Indonesia, Japan, Kazakhstan, South Korea, Kyrgyzstan, Laos, Macao, Malaysia, Maldives, Mongolia, Myanmar (ex-Burma), Nepal, Phillipines, Singapore, Sri Lanka (ex-Ceilan), Taiwan, Tajikistan, Thailand, Timor Leste (West), Turkmenistan, Uzbekistan, Vietnam

Albania, Andorra, Belarus, Bosnia, Croatia, European Union, Faroe Islands, Gibraltar, Guerney and Alderney, Iceland, Jersey, Kosovo, Liechtenstein, Macedonia, Man, Island of Moldova, Monaco, Montenegro, Norway, Russia, San Marino, Serbia, Svalbard and Jan Mayen Islands, Switzerland, Turkey, Ukraine, Vatican City State (Holy See)

Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, United Kingdom

Bahrain, Iraq, Iran, Israel, Jordan, Kuwait, Lebanon, Oman, Palestine, Qatar, Saudi Arabia, Syria, United Arab Emirates, Yemen