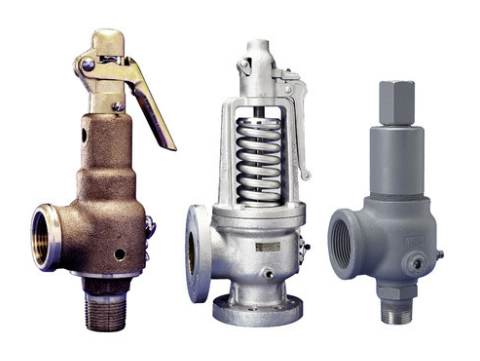

Safety Valve Supplier

Kaizen Steels is a leading supplier, stockist, exporter, and manufacturer of high-quality safety valves in India. Our safety valves are designed for various industries, including chemicals, steel, petrochemicals, fire protection, paper manufacturing, and shipping. Crafted using premium materials, our safety valves are built to meet international quality standards, ensuring reliability and durability.

We offer a wide range of safety valves that are engineered to control flow, pressure, temperature, and liquid levels. These valves operate by fully or partially opening or closing in response to signals from a controller. We also provide custom solutions to meet specific client needs.

Safety Valve Features

| Specification | Details |

|---|---|

| Size | 3/8″ – 10″ (10mm – 250mm) |

| Class | 150# – 1500# |

| Material of Construction (MOC) | CS / SS / Alloys / Monel / Hastelloy |

| Type | Open / Closed / Lever |

| Mechanism | Spring / Dead Weight |

| Nozzle Type | Semi Nozzle / Full Nozzle |

| Seat Type | Metal to Metal / Metal to Soft Seat |

Specialization Of Safety Valve

| Specification | Details |

|---|---|

| Design | ASME B16.34 / API 526 / API 520 |

| Face to End | API 526 |

| End to End | SW / SCR Type / Flanged End |

| End Flange | ASME B16.5 / DIN / BS / IS / JIS |

| SW End | ASME B16.11 |

| Test | API 527 |

| Set Pressure Test | As per Client Specification |

| Special | As per NACE MR-01-75 |

Key Terminology for Safety Valves

Overpressure: Pressure exceeding the safety valve’s set pressure.

Operating Pressure: The system’s normal working pressure during standard operation.

Set Pressure: The pressure point where the valve disc starts lifting to release pressure.

Lift: The distance the disc moves from its closed position to allow discharge.

Backpressure: The pressure at the valve outlet during discharge, consisting of built-up and superimposed back pressure.

Built-up Backpressure: The pressure at the outlet once the valve opens.

Superimposed Back Pressure: The pressure at the valve outlet when it’s still closed.

Maximum Allowable Working Pressure (MAWP): The highest pressure the system can safely handle at a given temperature, based on its weakest component.

Blowdown: The pressure difference between when the valve opens and when it closes, typically shown as a percentage.

Blow-off Capacity: The valve’s ability to release pressure at a specific rate.

Application of safety valves

Chemical plants

Oil and Gas

Petrochemical

Energy

LNG and PNG

Food Industries

Ship building

HVAC

Kaizen Steel Industries Export to

Burundi, Comoros, Djibouti, Eritrea, Ethiopia, Kenya, Madagascar, Malawi, Mauritius, Mayotte, Mozambique, Reunion, Rwanda, Seychelles, Somalia, Tanzania, United Republic of Uganda, Zambia, Zimbabwe, Angola, Cameroon, Central African Republic, Chad, Congo (Brazzaville), Congo, Democratic Republic of the Equatorial Guinea, Gabon, Sao Tome and Principe, Algeria, Egypt, Libyan Arab Jamahiriya, Morroco, South Sudan, Sudan, Tunisia, Western Sahara, Botswana, Lesotho, Namibia, South Africa, Swaziland, Benin, Burkina Faso, Cape Verde, Cote d\\’Ivoire (Ivory Coast), Gambia, Ghana, Guinea, Guinea-Bissau, Liberia, Mali, Mauritania, Niger, Nigeria, Saint Helena, Senegal, Sierra Leone, Togo

Anguilla, Antigua and Barbuda, Aruba, Bahamas, Barbados, Bonaire, Saint Eustatius and Saba, British Virgin Islands, Cayman Islands, Cuba, Curaçao, Dominica, Dominican Republic, Grenada, Guadeloupe, Haiti, Jamaica, Martinique, Monserrat, Puerto Rico, Saint-Barthélemy, St. Kitts and Nevis, Saint Lucia, Saint Martin, Saint Vincent and the Grenadines, Sint Maarten, Trinidad and Tobago, Turks and Caicos Islands, Virgin Islands (US), Belize, Costa Rica, El Salvador, Guatemala, Honduras, Mexico, Nicaragua, Panama, Argentina, Bolivia, Brazil, Chile, Colombia, Ecuador, Falkland Islands (Malvinas), French Guiana, Guyana, Paraguay, Peru, Suriname, Uruguay, Venezuela, Bermuda, Canada, Greenland, Saint Pierre and Miquelon, United States

Afghanistan, Armenia, Azerbaijan, Bangladesh, Bhutan, Brunei Darussalam, Cambodia, China, Georgia, Hong Kong, India, Indonesia, Japan, Kazakhstan, South Korea, Kyrgyzstan, Laos, Macao, Malaysia, Maldives, Mongolia, Myanmar (ex-Burma), Nepal, Phillipines, Singapore, Sri Lanka (ex-Ceilan), Taiwan, Tajikistan, Thailand, Timor Leste (West), Turkmenistan, Uzbekistan, Vietnam

Albania, Andorra, Belarus, Bosnia, Croatia, European Union, Faroe Islands, Gibraltar, Guerney and Alderney, Iceland, Jersey, Kosovo, Liechtenstein, Macedonia, Man, Island of Moldova, Monaco, Montenegro, Norway, Russia, San Marino, Serbia, Svalbard and Jan Mayen Islands, Switzerland, Turkey, Ukraine, Vatican City State (Holy See)

Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, United Kingdom

Bahrain, Iraq, Iran, Israel, Jordan, Kuwait, Lebanon, Oman, Palestine, Qatar, Saudi Arabia, Syria, United Arab Emirates, Yemen